Permanent shuttering cast-in-place extra light concrete self-insulation composite wall body and construction technology

A permanent formwork and composite wall technology, applied in thermal insulation, walls, building components, etc., can solve the problems of difficult control of construction quality, limited external finishing layer, complicated construction process, etc., and achieve easy engineering quality assurance and manufacturing price. Inexpensive, widely sourced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments are given below in conjunction with the accompanying drawings, and the permanent template cast-in-place ultra-lightweight concrete composite wall of the present invention and its construction technology are described in detail.

[0024] In an embodiment, the welded steel grid frame 3 is determined according to the building design and the thickness of the insulation layer, and according to the construction requirements.

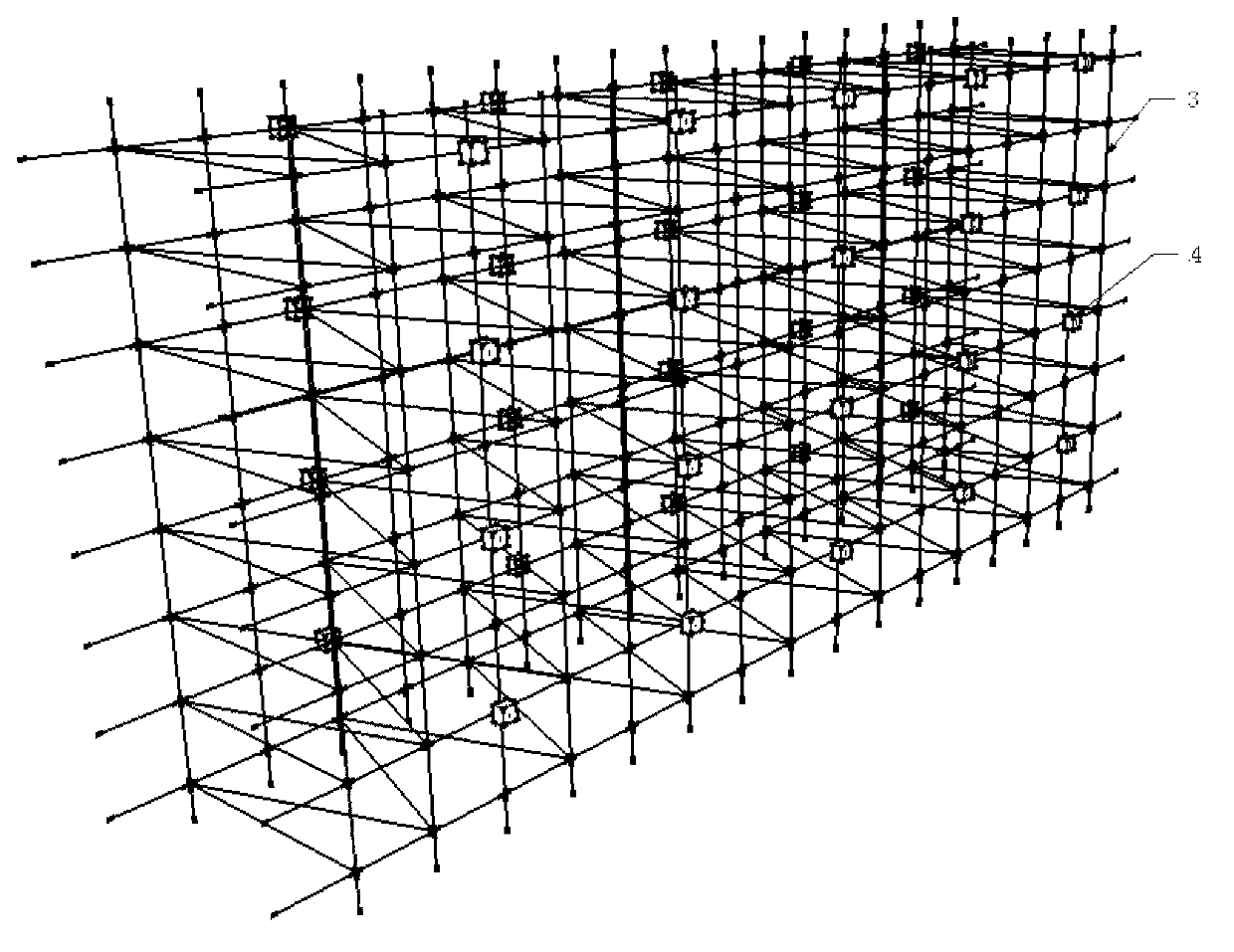

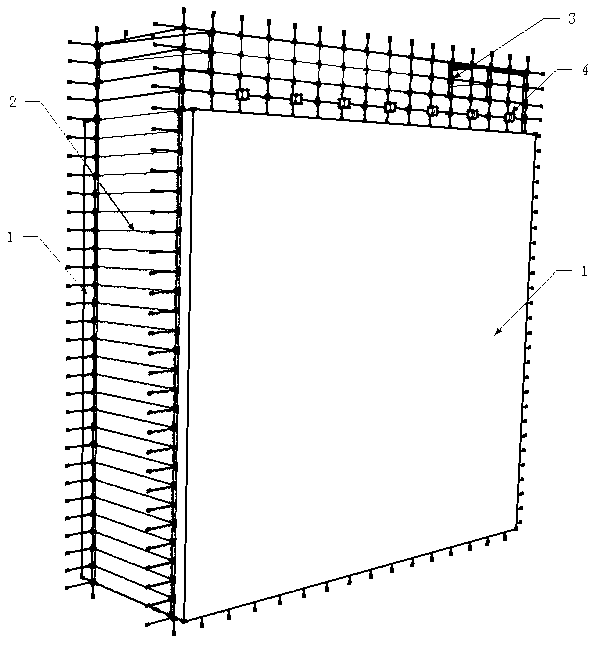

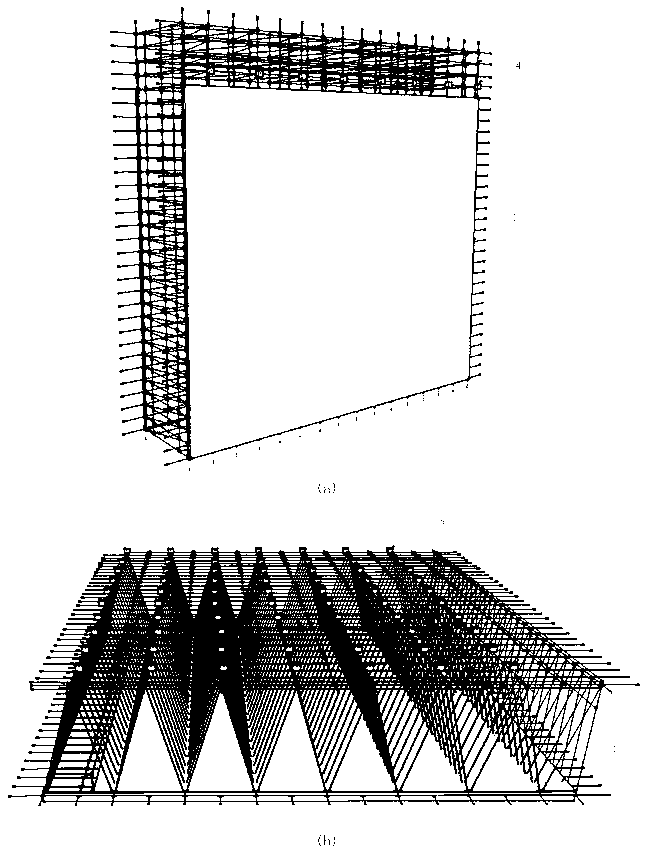

[0025] Fabrication of welded steel mesh frame 3 in the factory (see image 3 ), binding the prefabricated concrete protective layer block 4; paving high-performance concrete in the mold, then laying steel wire mesh or fiber mesh, and scraping to make fiber-reinforced high-performance concrete layer 1, that is, the inner permanent formwork; welding the steel mesh Rack 3 is pressed into the inner permanent formwork (see figure 2 ), conservation. The fiber-reinforced high-performance concrete layer 1 is made in another mold, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com