Static force hydroenergy water feeder

A water supply and static technology, applied in the direction of machines/engines, liquid variable displacement machines, piston pumps, etc., can solve the problems of low pressure, small suction height, small flow, etc., and achieve wide application fields and low production costs , The effect of pump pressure enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

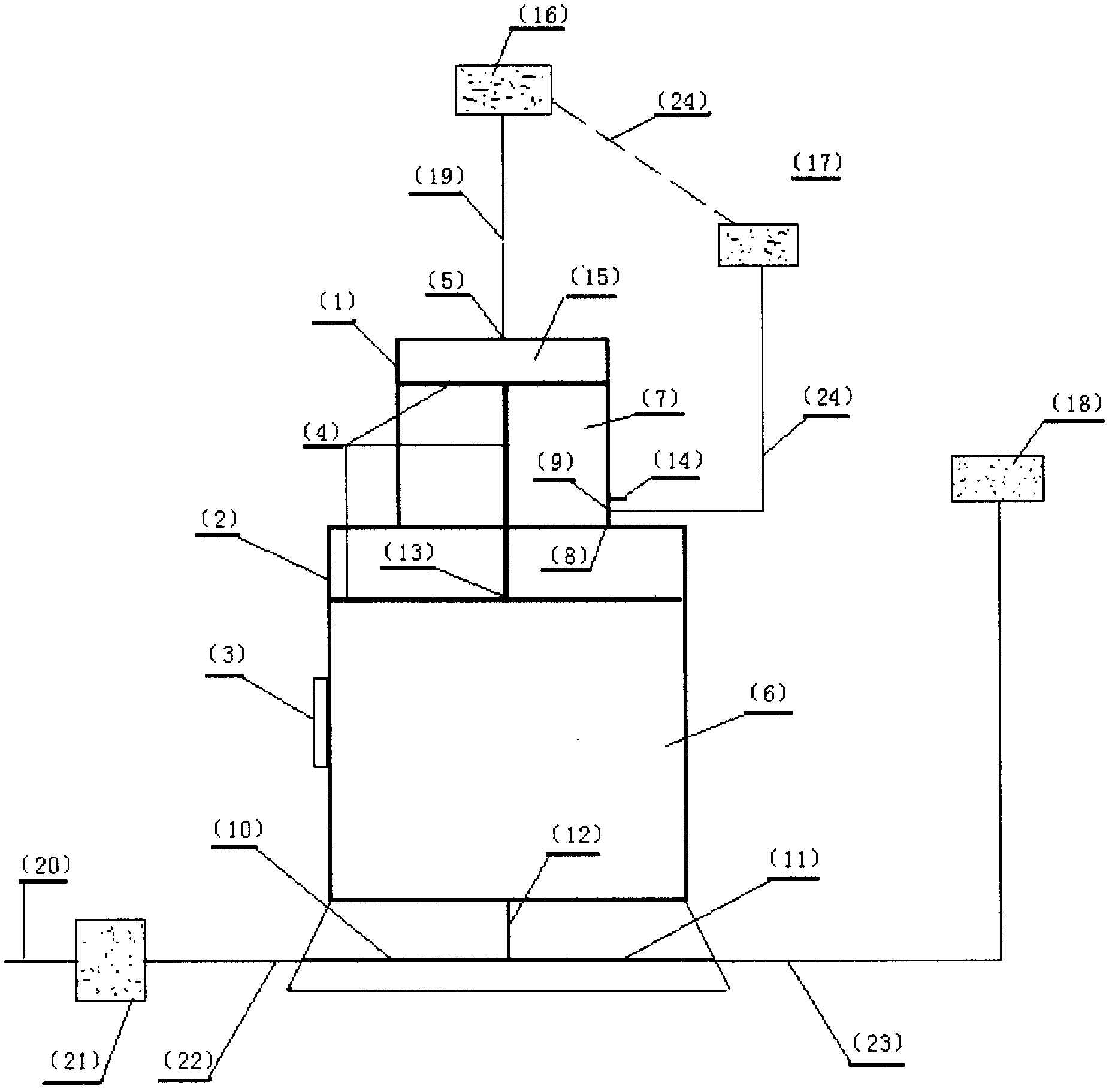

[0018] Example: refer to figure 1 : the present embodiment comprises upper pump cylinder (1), lower pump cylinder (2), electrical connection controller (3), piston assembly link rod (4), piston assembly water inlet valve (5), water storage cylinder ( 6), pump cylinder working chamber (7), piston travel switch (8), return water check valve (9), water inlet check valve (10), drain check valve (11), pump cylinder inlet and outlet pipes (12 ), piston assembly guide regulator (13), pump cylinder studio vacuum regulator (14), water storage tank (15), high platform (16) (namely mother water source), second high platform (17), high-rise water storage Pond (18), female water head (19), external water source (20), low level reservoir (21), water feeder inlet pipe (22), water feeder drain pipe (23), female water return pipe (24 ).

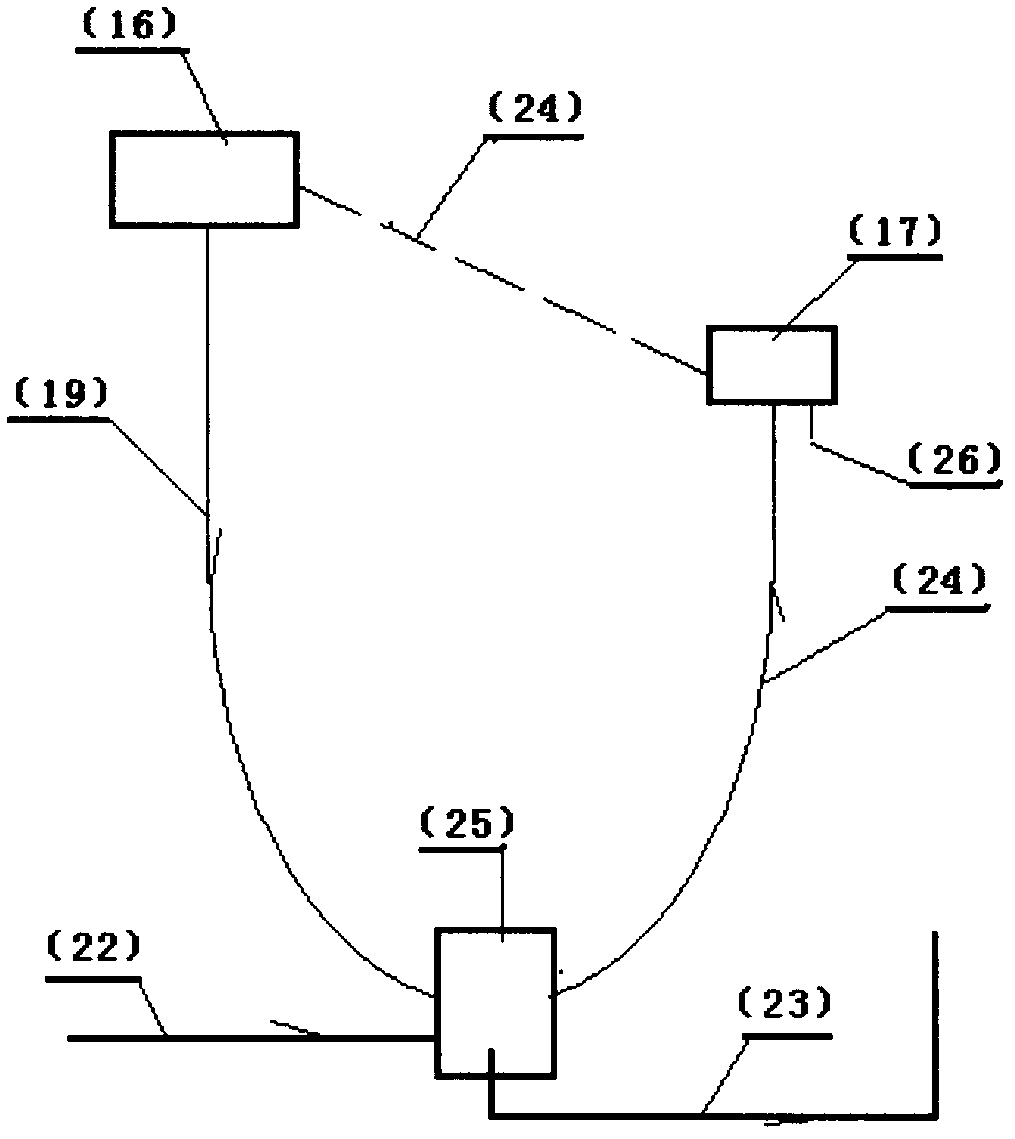

[0019] refer to figure 2 : high platform (16) (i.e. mother water source), sub-high platform (17), mother water head (19), water feeder inlet pipe (22), w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com