Friction disks of clutch

A friction disc and clutch technology, applied in the field of friction discs, can solve the problem of increased inertia power loss of clutches, and achieve the effect of reducing the structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

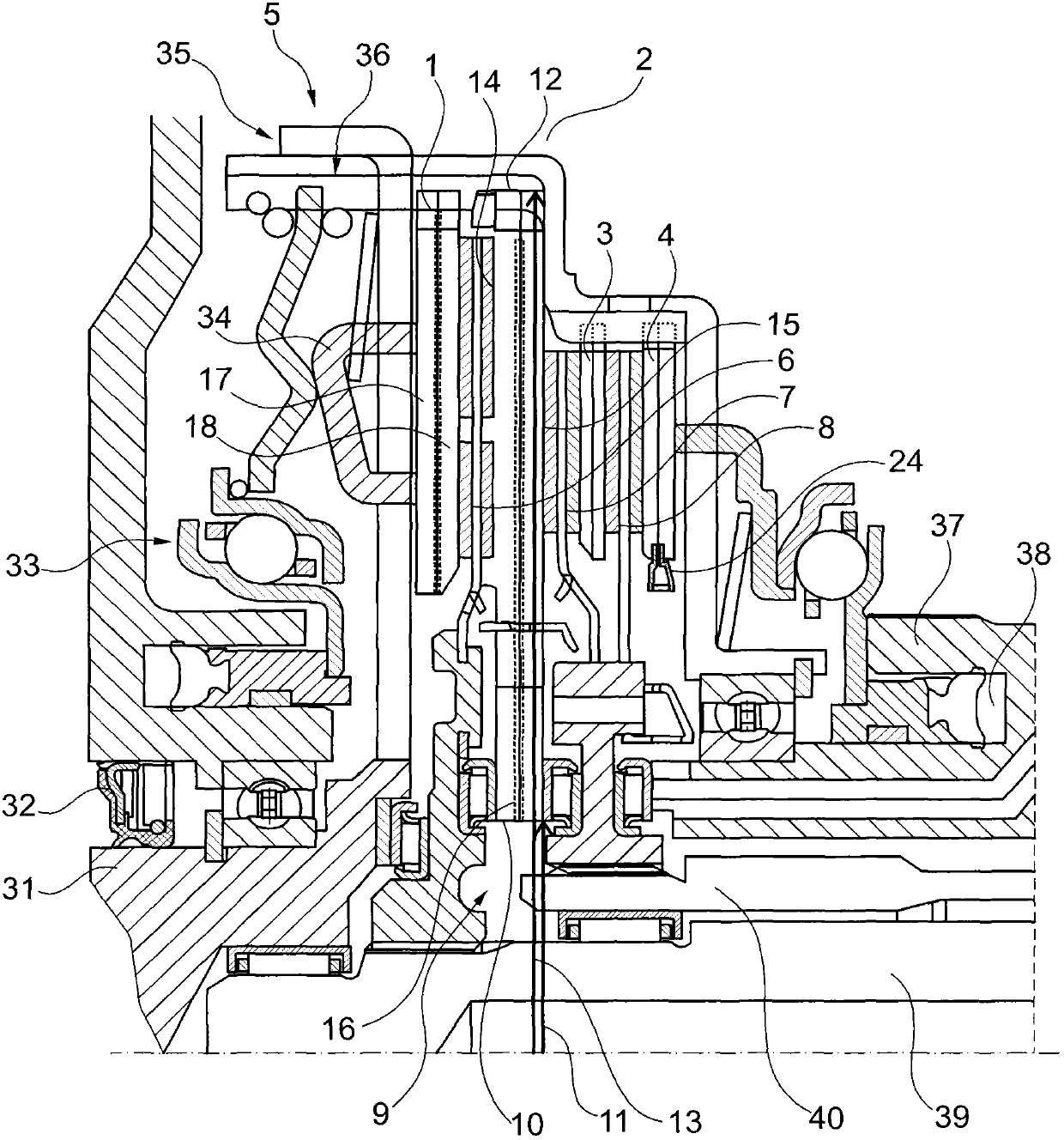

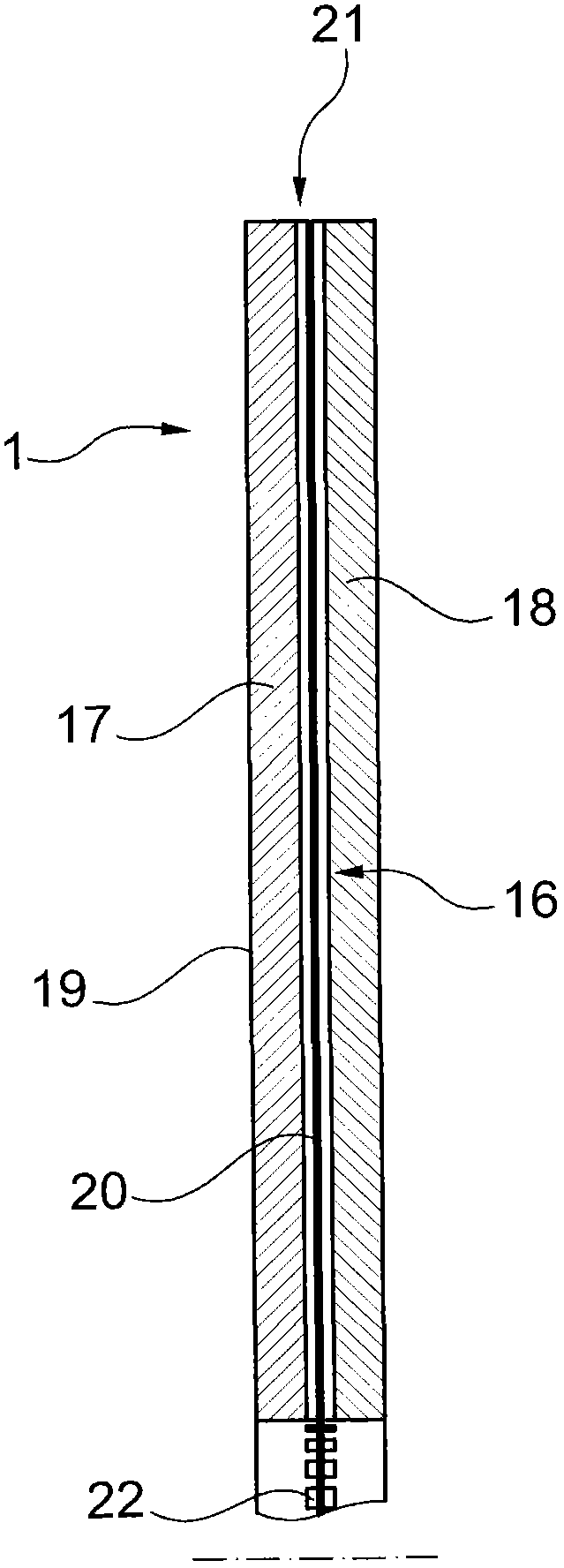

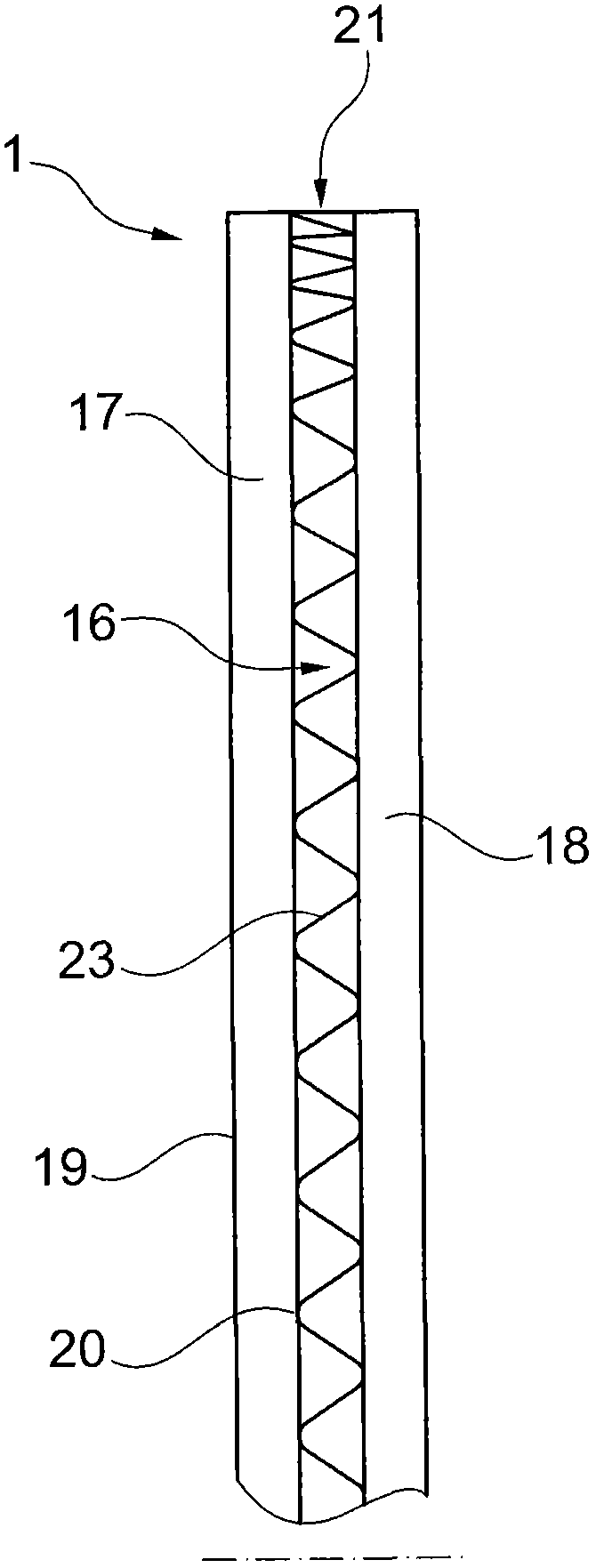

[0036] figure 1 The clutch 5 is shown here as a double clutch and has a central web 2 with internally cooled friction disks—here first pressure plate 1 , central web 2 , second pressure plate 3 and third pressure plate Compression plate 4. Arranged between the first pressure plate 1 and the central web 2 is a first clutch disc 6 , which is connected to a first transmission shaft 39 . A second clutch disk 7 is arranged between the second pressure plate 3 and the central web 2 , and a third clutch disk 8 is arranged between the third pressure plate 4 and the second pressure plate 3 . The second clutch disk 7 and the third clutch disk 8 are jointly connected to the second transmission shaft 40 . All friction disks shown have a through hole in the center 9 . An inner edge 10 with an inner diameter 11 is thus formed on the side directed toward the center 9 . An outer edge 12 with an outer diameter 13 is formed on the maximum radial extent of the friction disk. As an example, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com