Carrier for electrical component

A technology of electrical components and carriers, applied in the direction of electrical equipment structural parts, electrical components, electrical equipment shells/cabinets/drawers, etc., can solve problems such as high investment costs, high development costs of module shells, long manufacturing process time, etc., to achieve The effect of simplifying components, simplifying manufacturing, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

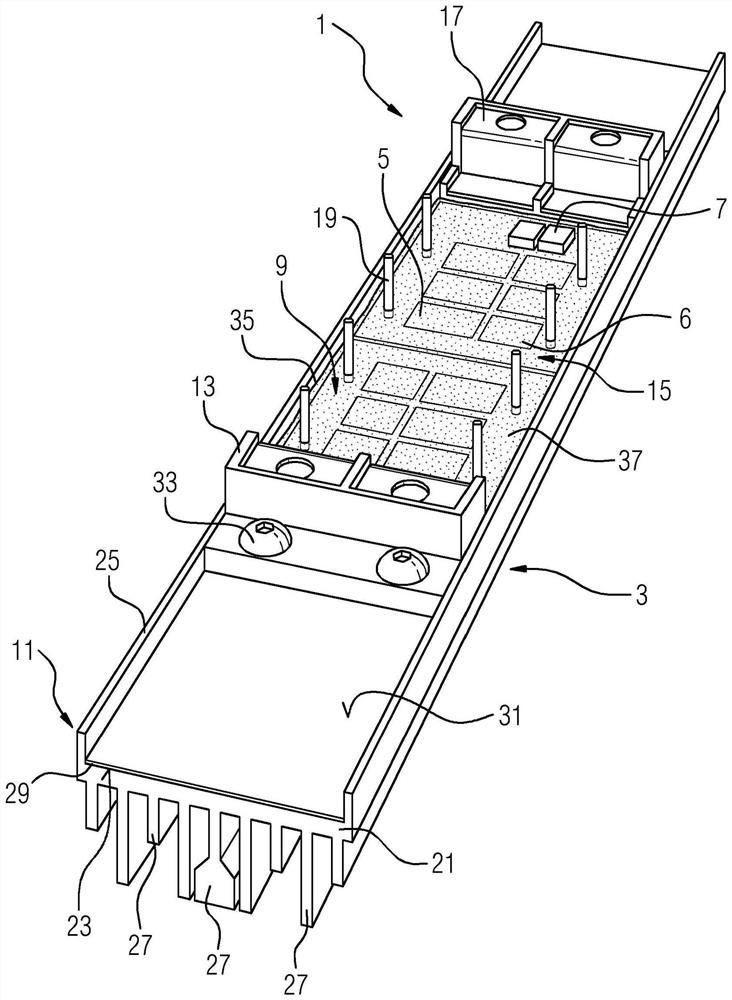

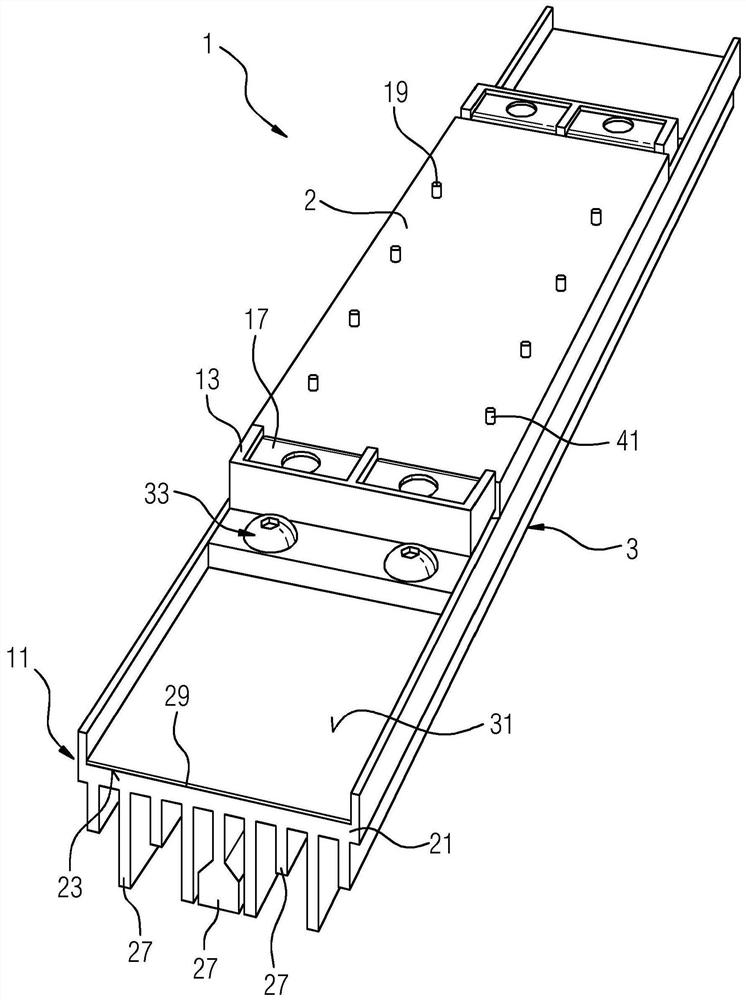

[0028] attached figure 1 And attached figure 2 ( figure 1 with figure 2 ) respectively show a perspective view of a first embodiment of the electronic module 1 according to the invention. here, figure 1 shows the electronics module 1 without the cover 2 and figure 2 Electronics module 1 with cover 2 is shown. Electronics module 1 comprises a carrier 3 according to the invention, electrical components 5 to 7 and a potting compound 9 .

[0029] The carrier 3 comprises a cover 2 , a heat sink 11 , two sealing blocks 13 , a carrier structure 15 , connecting webs 17 and pin-shaped connecting contacts 19 .

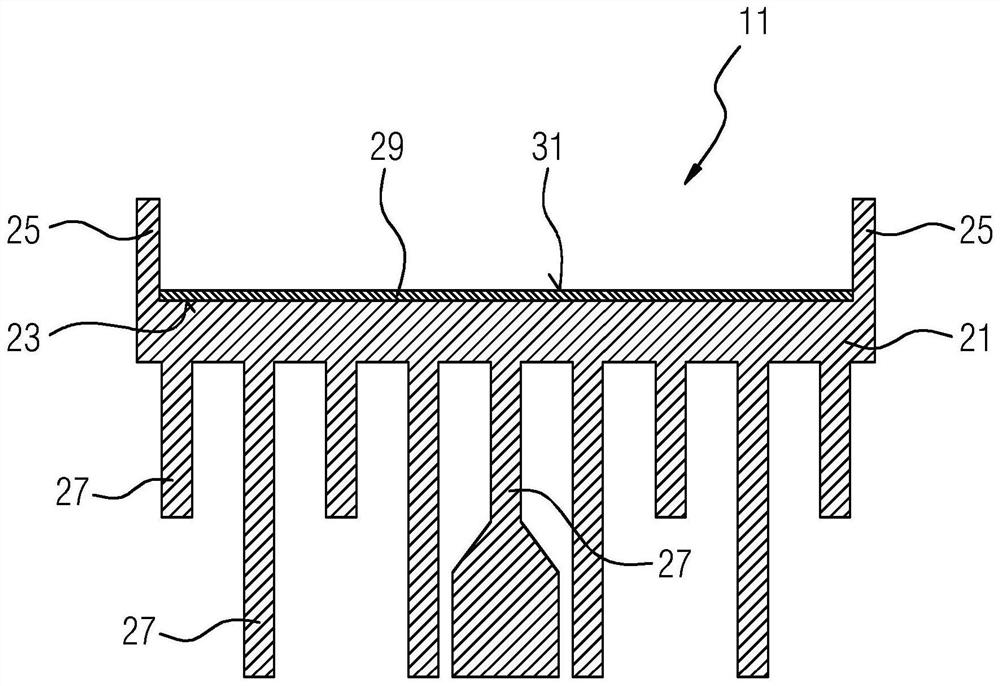

[0030] attached image 3 ( image 3) shows a cross-sectional view of the heat sink 11 . The heat sink 11 has a base body 21 with a planar base body surface 23 on the upper side and two opposite side walls 25 protruding from the base body surface 23 and a plurality of cooling fins 27 on the lower side. The base body surface 23 is coated with a heat dissipation layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com