Dynamic triaxial testing machine servo-driven by electric cylinder

A dynamic three-axis test and servo-driven technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large footprint, insufficient precision, and large pollution, and achieve small footprint, high precision, and ease of use. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

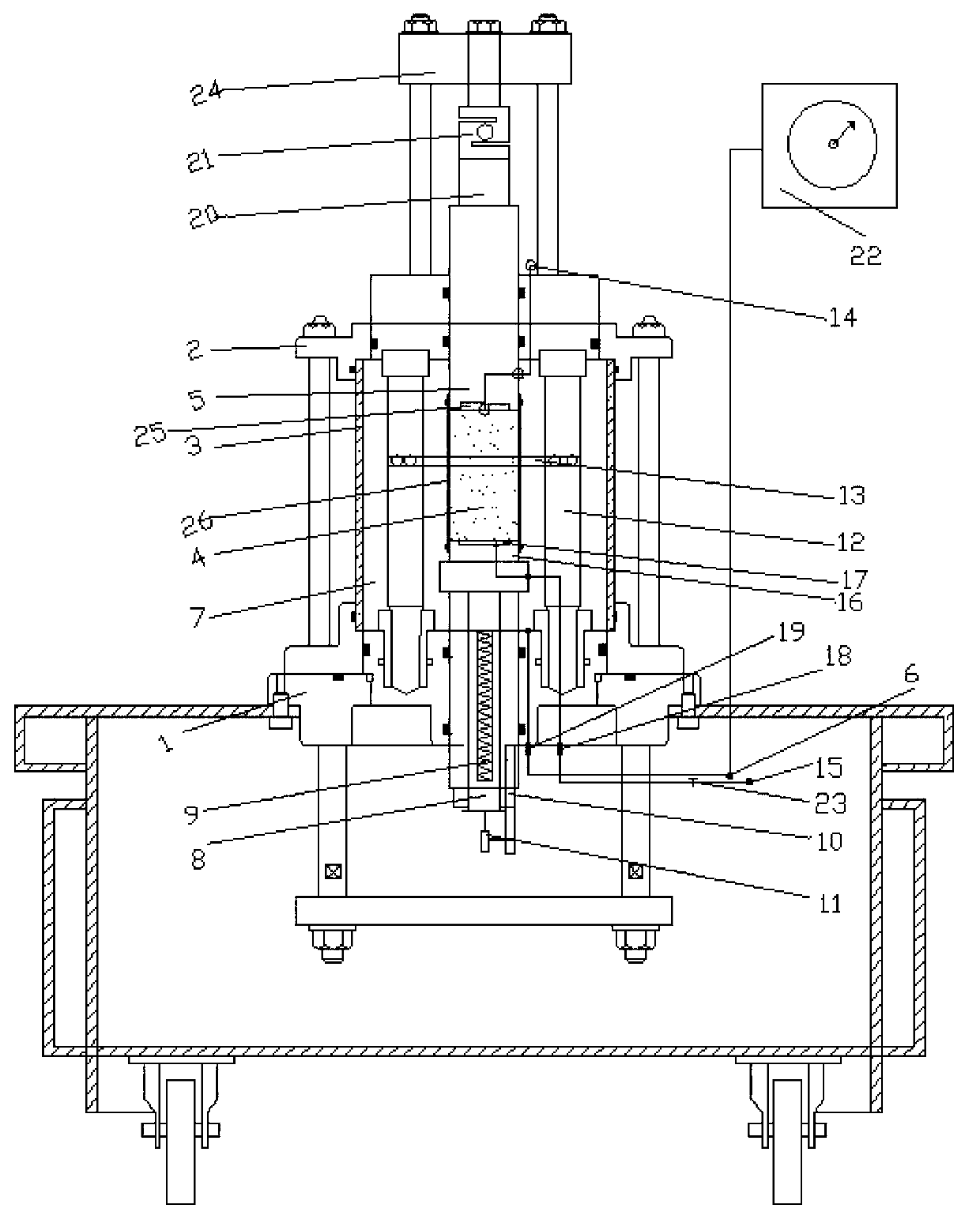

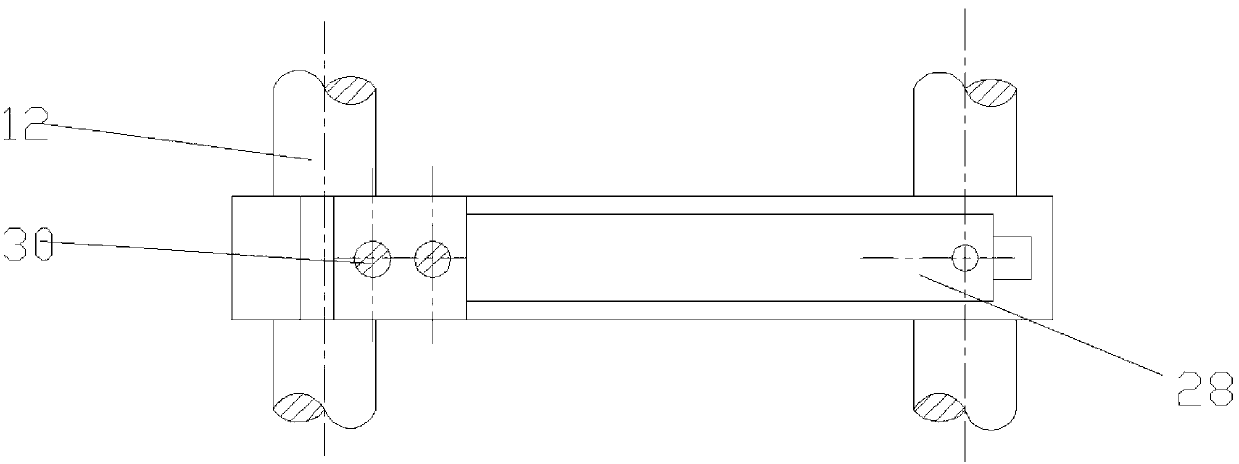

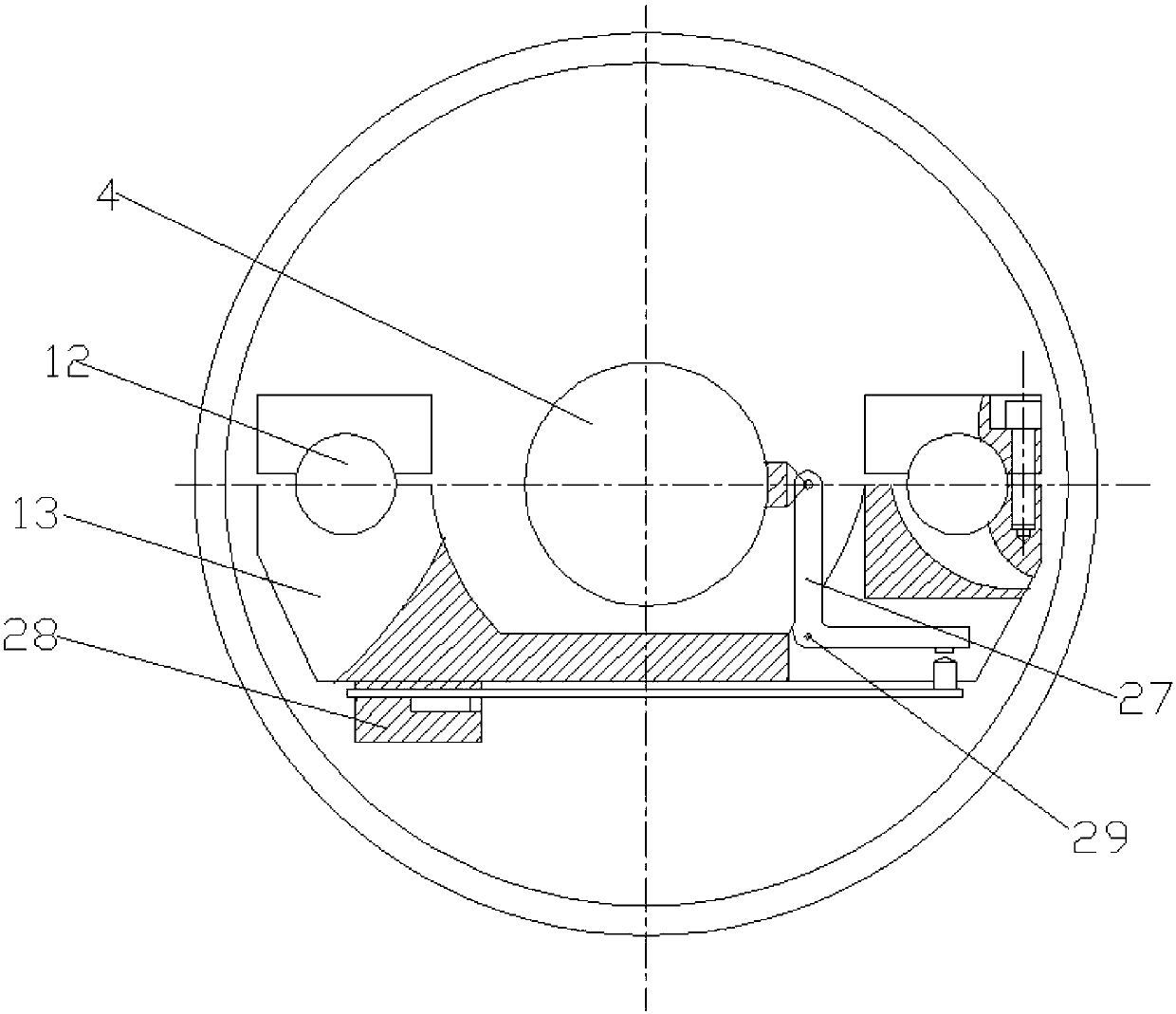

[0026] The invention is a dynamic three-axis testing machine driven by an electric cylinder servo, and its structure includes a main body and a control part. The main body includes the confining pressure loading part and the pore water pressure part, which are the core of applying load to the sample; the confining pressure loading part applies surrounding pressure to the sample through the air source, and the vertical static load and vertical dynamic load pass through the servo electric cylinder The reciprocating motion of the sample loads the sample; the pore water pressure is partly connected to the pressure sensor of the drain pipe of the sample base for measurement. The control part and the main part work in unison and coordinate to jointly realize the detection purpose of the device of the present invention.

[0027] refer to figure 1 , the structure of the device of the present invention is that a pressure chamber base 1 is fixedly installed on the table of the mobile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com