Ablation test method of thermal protection structure of high supersonic velocity aircraft

A thermal protection structure, hypersonic technology, applied in the field of aerospace experiments, can solve the problems of difficult, impossible, and inconvenient measurement of ablation amount, and achieve the effects of rich measurement results, improved comprehensive accuracy, and simple requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

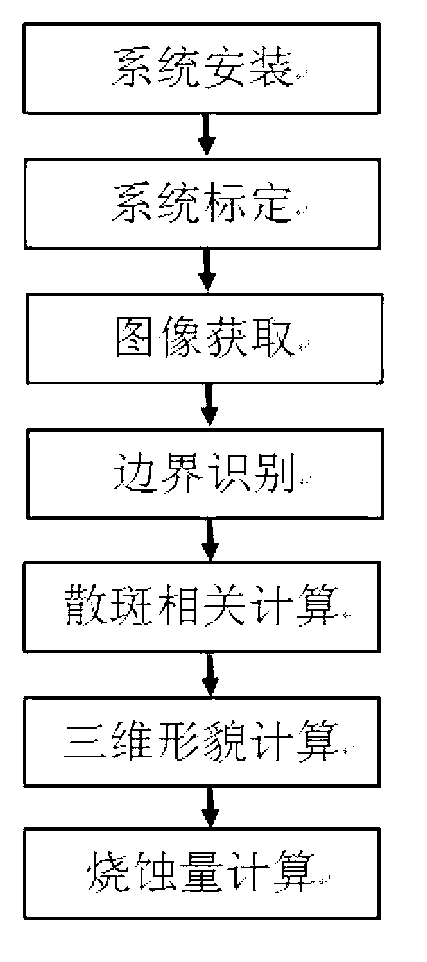

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

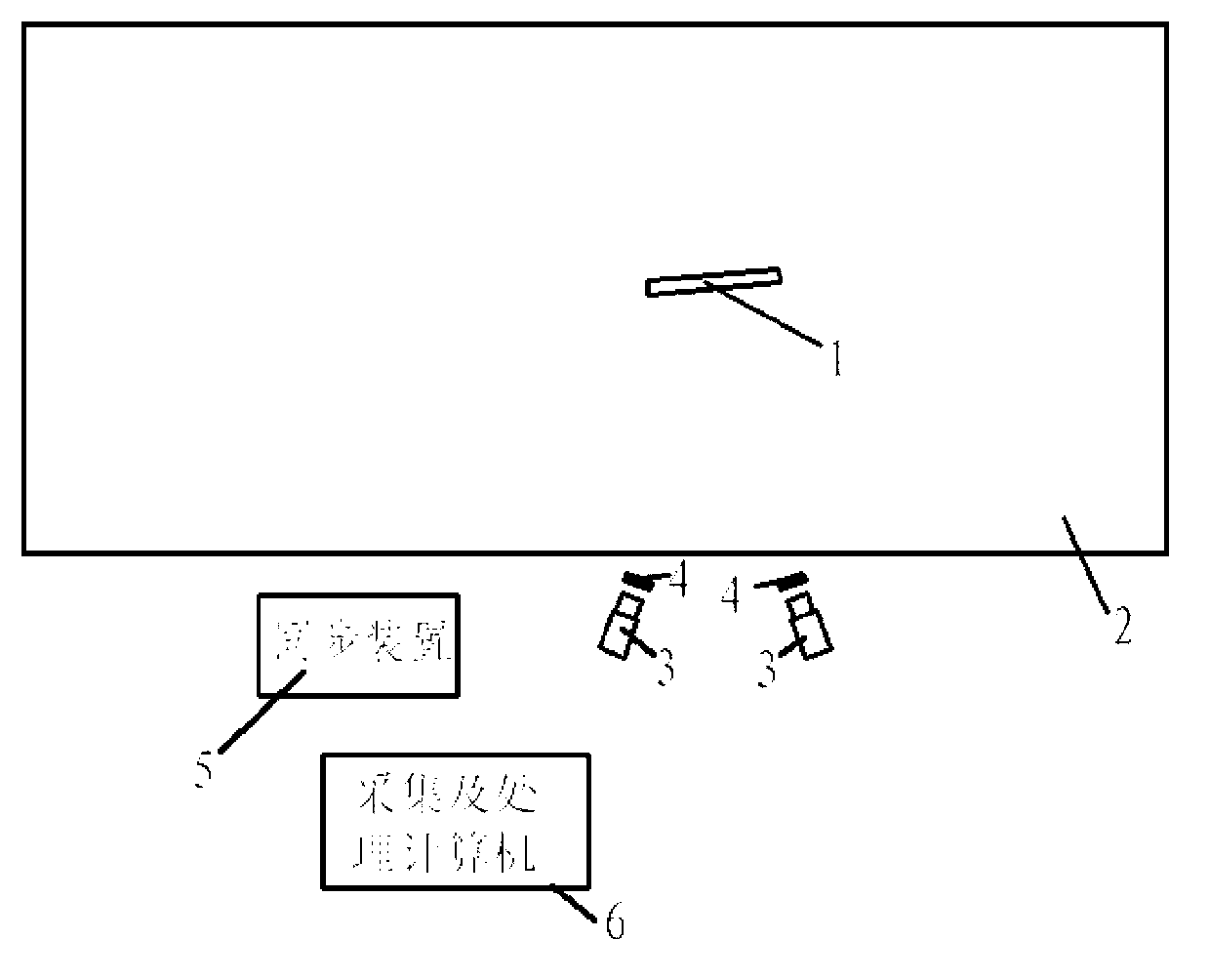

[0035] Such as figure 2 As shown, the test system used to realize the ablation test of the thermal protection structure of the hypersonic vehicle includes two cameras 3, a filter device 4 installed in front of each camera, a synchronization device 5, and an acquisition and processing computer 6; Two cameras 3 equipped with filter devices 4 are symmetrically arranged outside the arc wind tunnel 2 with respect to the object to be measured. The computer 6 uses the synchronization device 5 to drive the CCD camera 3 to collect images, and the computer 6 performs image collection and processing. . After the test starts, the computer 6 uses the synchronous device 5 to drive the CCD camera 3 to collect images of the measured object 1. During the collection, the filter device 4 can be adjusted in real time to select the light intensity to obtain the best image quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com