A kind of light diffusion plate and its production method

A technology of a light diffusion plate and a manufacturing method, which is applied in optics, optical components, instruments, etc., can solve the problems of decreased light transmittance, inconspicuous light spots, practical limitations, etc., and achieves reduced thickness and weight, small volume and weight, Good dodging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a light diffusion plate, the light diffusion plate is used in the field of LED lighting, and the light diffusion plate is made by the following method:

[0038] (1) direct forming a thickness by thermal extrusion is a transparent PC board 11 as the base material;

[0039] (2) Print a layer of light-diffusing ink with a thickness of 1 μm by jet printing on a flat side of the transparent PC board 11, and then dry the light-diffusing ink to form the first light on the transparent PC board base material. Diffusion layer 12;

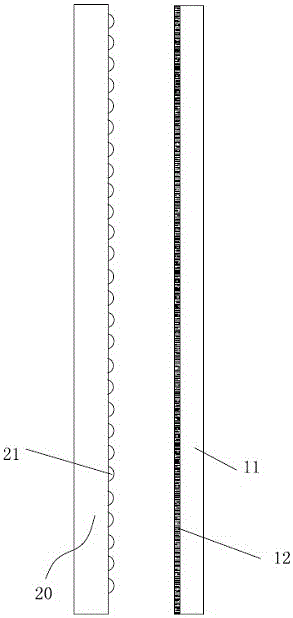

[0040] (3) Install the above-mentioned light diffusion plate with the first light diffusion layer and the LED light source 20 with a plurality of light-emitting points 21, so that the side with the first light diffusion layer is opposite to the LED light source, such as figure 1 shown;

[0041] (4) Use a two-dimensional color analyzer to measure the luminance distribution of the light-emitting surface of the above-mentioned l...

Embodiment 2

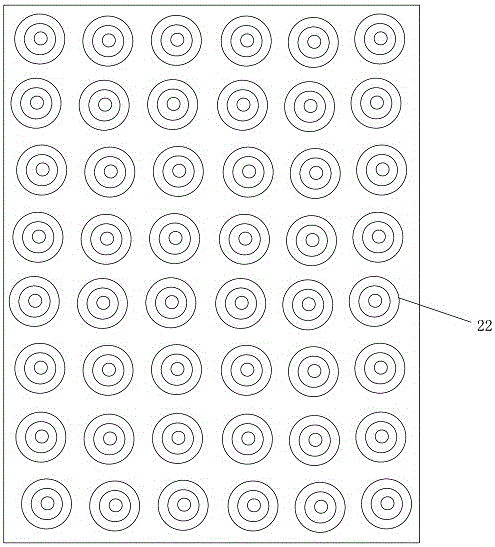

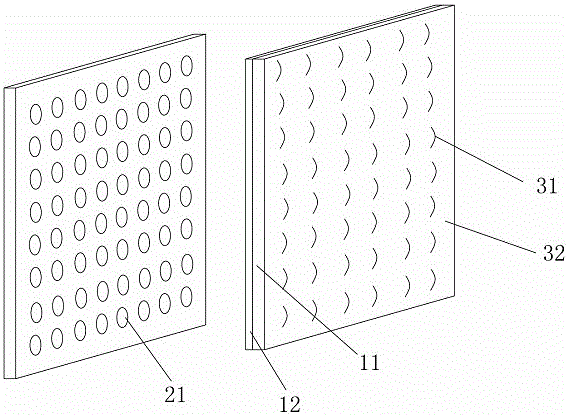

[0048] The difference between this embodiment and Embodiment 1 is that another light diffusion plate is provided, which is used in the field of LED display, such as Figure 5 As shown, the light diffusion plate of the present embodiment includes a transparent PMMA plate 11, the transparent PMMA plate is a base material, and a first light diffusion layer 12 is bonded on a flat side of the transparent PMMA plate. The surface of the first light-diffusing layer is a plane, and a second light-diffusing layer is bonded on the first light-diffusing layer. The distance is the same as the distance between the centers of two light-emitting points 21 . The side surface with the plurality of protrusions 31 serves as the light emitting surface of the light diffusion plate. When the protrusion is magnified to 10 times, it can be found that the protrusion 31 includes a plurality of micro-light diffusion layers micro-light diffusion layer 311 distributed in steps, and the midline phase of th...

Embodiment 3

[0058] The light diffusion plate provided in this embodiment is the same as the light diffusion plate provided in embodiment 1, but different from embodiment 1, the light emitting surface 32 of the light diffusion plate is a flat light diffusion layer 12, and the second light diffusion layer is the same as The luminous point 21 of the LED light source 20 is opposite, such as Figure 7 shown. The manufacturing method of this light-diffusion plate is also the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com