Single-refrigeration water-source heat pump grain cooling unit

A technology of water source heat pump and cooling unit, which is applied in the direction of preserving seeds, refrigerators, and refrigeration components by freezing/cooling, which can solve the problems of increasing air-side flow resistance, reducing refrigeration efficiency, and increasing operating energy consumption, so as to reduce the The effect of outlet temperature fluctuation, improving cooling efficiency and reducing installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

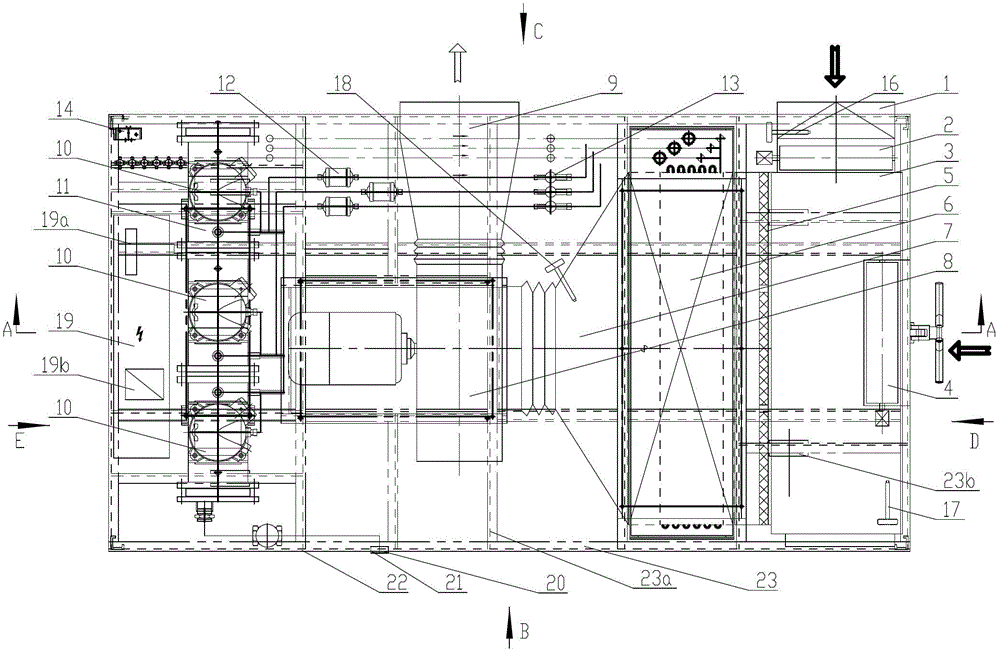

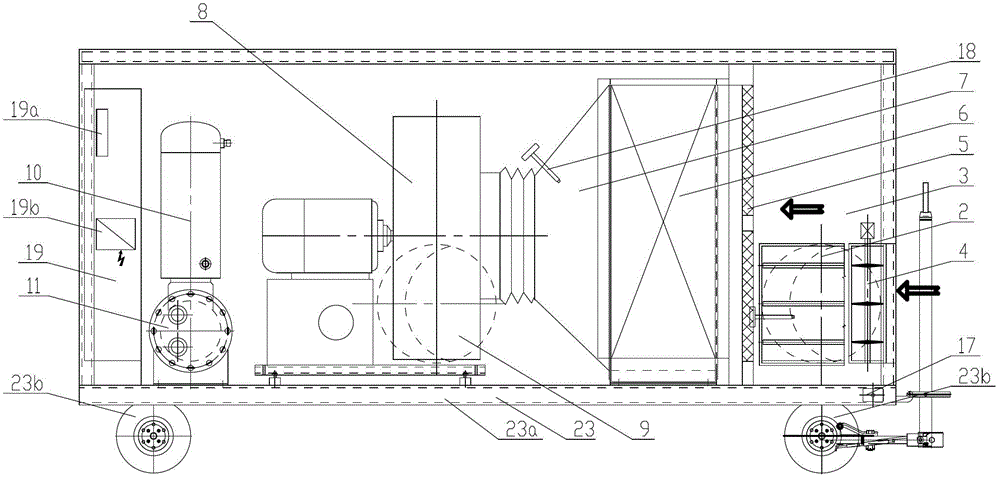

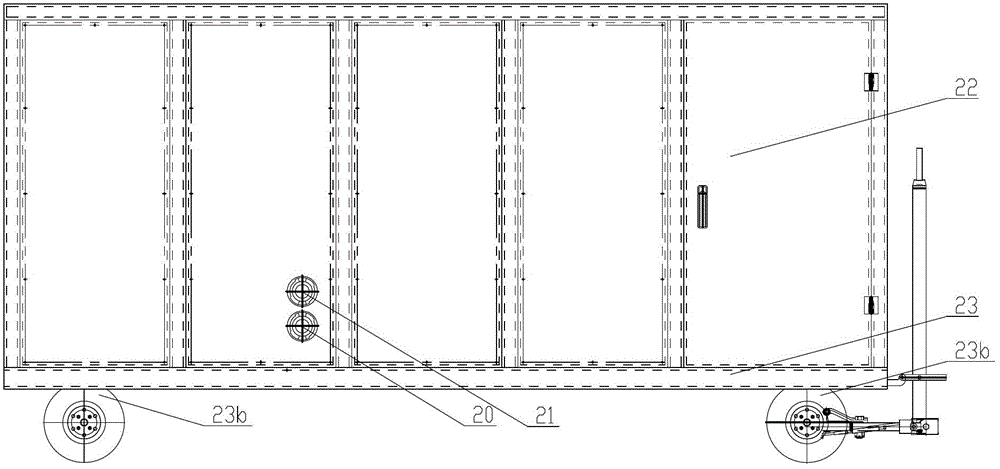

[0042] The present invention will be further described below in conjunction with specific drawings.

[0043] Such as Figure 1 to Figure 11 As shown: the single-cooling water source heat pump grain cooling unit and the low-temperature cooling system of the granary include the return air connection pipe 1, the return air electric valve 2, the air mixing box 3, the fresh air electric valve 4, the coarse filter 5, and the direct evaporative air cooling 6, air collecting pipe 7, direct-connected centrifugal fan 8, air supply connecting pipe and interface 9, refrigeration compressor 10, three-stage water-cooled condenser with shell and tube 11, dry filter 12, electronic expansion valve 13, high and low pressure controller 14. Filling valve 15, return air temperature and humidity sensor 16, fresh air temperature and humidity sensor 17, outlet air temperature and humidity sensor 18, control box 19, PLC controller 19a, fan inverter 19b, condenser cooling water inlet interface 20, Conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com