Preparation method of reconstituted tobacco with aroma characteristic strengthening effect

A technology for remanufacturing tobacco leaves and aroma, which is applied in the direction of preparing tobacco, tobacco, and treating tobacco to achieve industrialized production, good development and application prospects, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

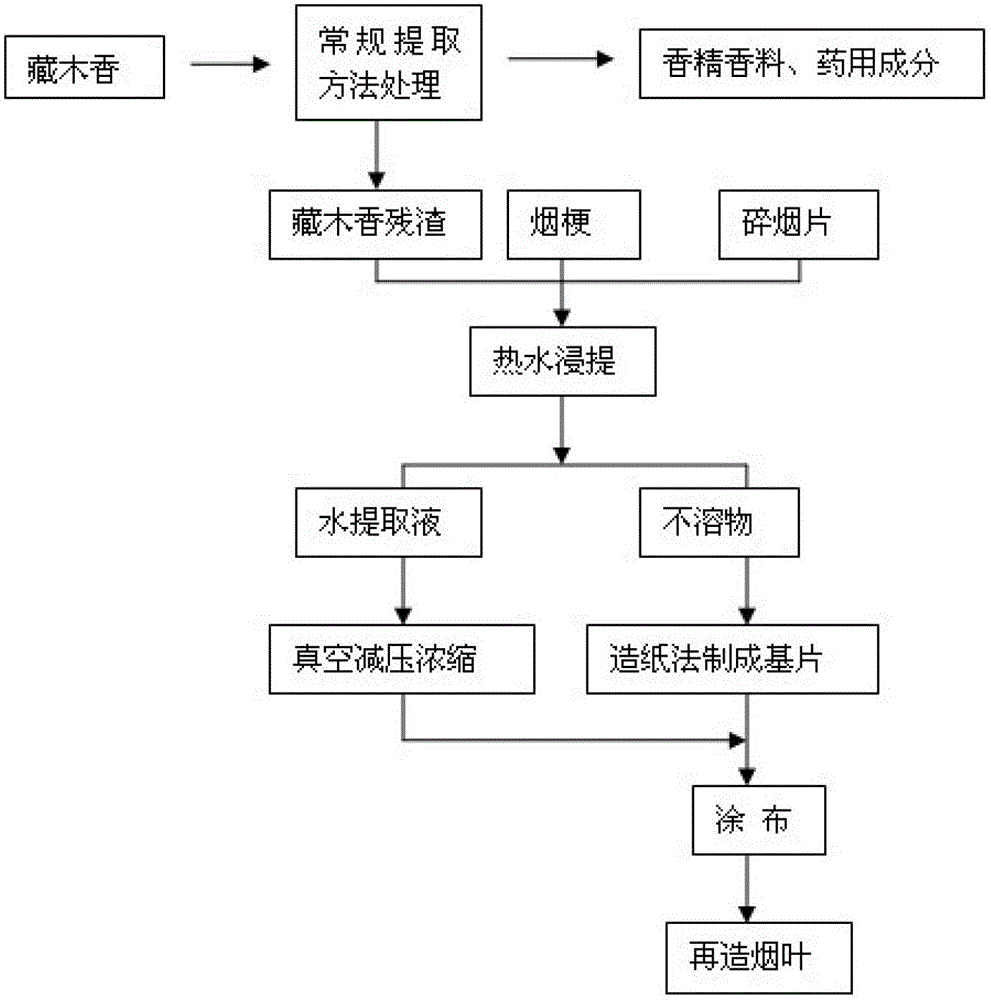

[0022] Example 1——Preparation and application of reconstituted tobacco leaves with enhanced aroma characteristics 1

[0023] 1. Preparation of reconstituted tobacco leaves

[0024] (1) Extract 100 g of Tibetan woody incense, 600 g of tobacco stems and 300 g of tobacco fragments with water at 60°C for 90 min, and separate the water extract and insoluble matter;

[0025] (2) Beat the insoluble matter, apply papermaking technology and equipment, and make a substrate;

[0026] (3) Vacuum concentrate the water extract to a density of 1-1.2 g / cm 3 , and backcoat the concentrated solution on the formed substrate to obtain the required reconstituted tobacco leaves.

[0027] 2. Addition experiments in cigarettes

[0028] The prepared shredded reconstituted tobacco leaves were applied to the Yunyan (impression) leaf group formula at a ratio of 6%, and the leaf group mixed with reconstituted tobacco leaves without Tibetan woody fragrance was used as the control group.

[0029] 3. Smo...

Embodiment 2

[0033] Example 2——Preparation and application of reconstituted tobacco leaves with enhanced aroma characteristics 2

[0034] 1. Preparation of reconstituted tobacco leaves

[0035] (1) Extract 100 g of Tibetan woody incense, 500 g of tobacco stems and 400 g of tobacco fragments with water at 70°C for 60 min, and separate the water extract and insoluble matter;

[0036] (2) Beat the insoluble matter, apply papermaking technology and equipment, and make a substrate;

[0037] (3) Vacuum concentrate the water extract to a density of 1-1.2 g / cm 3 , and backcoat the concentrated solution on the formed substrate to obtain the required reconstituted tobacco leaves.

[0038] 2. Addition experiments in cigarettes

[0039] The prepared shredded reconstituted tobacco leaves were applied to the Yunyan (impression) leaf group formula at a ratio of 6%, and the leaf group mixed with reconstituted tobacco leaves without Tibetan woody fragrance was used as the control group.

[0040] 3. Smo...

Embodiment 3

[0044] Example 3——Preparation and application of reconstituted tobacco leaves with enhanced aroma characteristics 3

[0045] 1. Preparation of reconstituted tobacco leaves

[0046] (1) Extract 200 g of Tibetan woody incense, 500 g of tobacco stems and 300 g of tobacco fragments with water at 90°C for 30 min, and separate the water extract and insoluble matter;

[0047] (2) Beat the insoluble matter, apply papermaking technology and equipment, and make a substrate;

[0048] (3) Vacuum concentrate the water extract to a density of 1-1.2 g / cm 3 , and backcoat the concentrated solution on the formed substrate to obtain the required reconstituted tobacco leaves.

[0049] 2. Addition experiments in cigarettes

[0050] The prepared shredded reconstituted tobacco leaves were applied to the Yunyan (impression) leaf group formula at a ratio of 6%, and the leaf group mixed with reconstituted tobacco leaves without Tibetan woody fragrance was used as the control group.

[0051] 3. Smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com