Device for preparing alloy with uniform organization and performance

A technology with high performance and uniformity, applied in metal extrusion control equipment, metal extrusion, manufacturing tools, etc., can solve the problems of small deformation, inability to achieve continuous material preparation, etc., to achieve low production cost, high production efficiency, and product high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with embodiment (accompanying drawing):

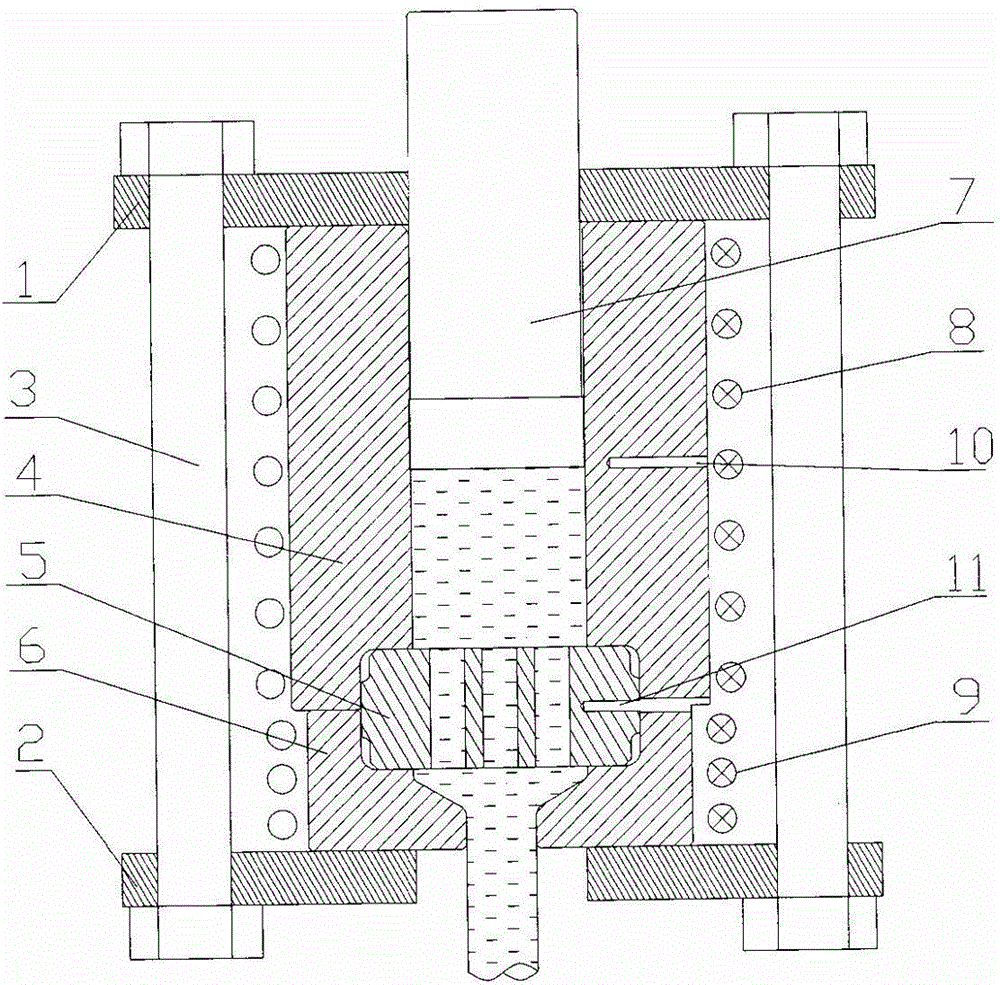

[0029] Such as figure 1 As shown, the device for preparing uniform fine-grained materials using multi-channel shunt extrusion technology in the present invention includes a frame body composed of an upper platen (1), a lower platen (2), and connecting guide bolts (3), which are arranged on the upper and lower The extrusion barrel (4) between the pressing plates, the multi-channel extrusion die (5), the single extrusion die (6), and the extrusion rod (7) placed in the extrusion barrel; The pressure barrel (4) and the single extrusion die (6) are assembled together in a coaxial and interlocking manner, and the multi-channel extrusion die (5) is buckled on the extrusion barrel (4) and the single extrusion die (6). In the extrusion die installation cavity added on the inner wall of the interlocking end of the extrusion die (6); the extrusion barrel (4) and the outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com