Equipment special for girth welding of steel pipe and welding neck flange

A high-neck flange and special equipment technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of unstable welding quality, low efficiency and high cost, and achieve simple structure, high production efficiency, The effect of stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

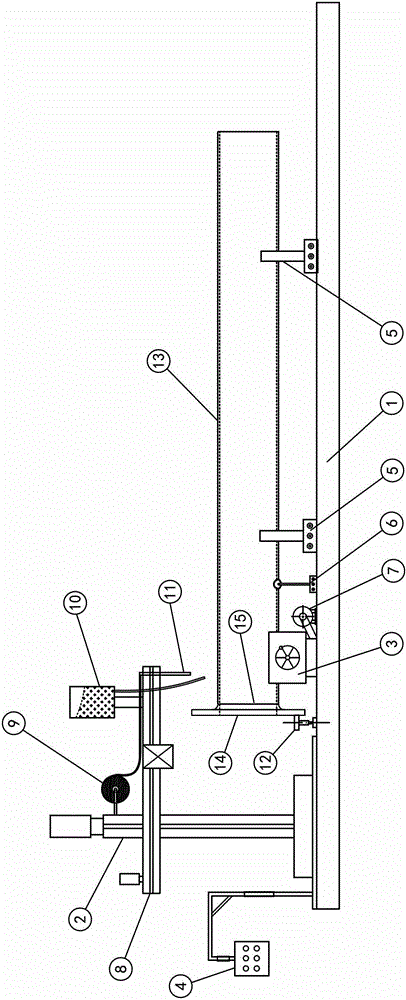

[0022] Embodiment: the special equipment for welding steel pipe and high neck flange girth welding of the present invention, as attached figure 1 As shown, it includes a platform 1, a console 4 and a welding device. The platform 1 is provided with a fixed tooling 5 for placing steel pipes 13 and flanges 14 to be welded and a steel pipe automatic rotation mechanism that drives the steel pipe 13 to rotate at a constant speed.

[0023] The platform 1 is provided with a lifting mechanism 2, a horizontal moving mechanism 8 that can move laterally on the lifting mechanism 3, and the end of the horizontal moving mechanism 8 is fixed with a welding head 11 of the welding device; the lifting mechanism 2 and the horizontal moving mechanism 8 work together Next, the end of the fixed welding head of the horizontal moving mechanism 8 and the welding head 11 can extend into the steel pipe 13 from the flange end and reach the welding position of the inner weld seam, so as to perform welding o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com