Electric hydraulic pressure servo valve

A servo valve, pressure technology, applied in the direction of control valve and bleed valve, brake assembly, aircraft brake arrangement, etc., can solve problems such as the inability to meet the requirements of aircraft brake anti-skid control, improve work stability, prevent pollutants hazards, good job stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

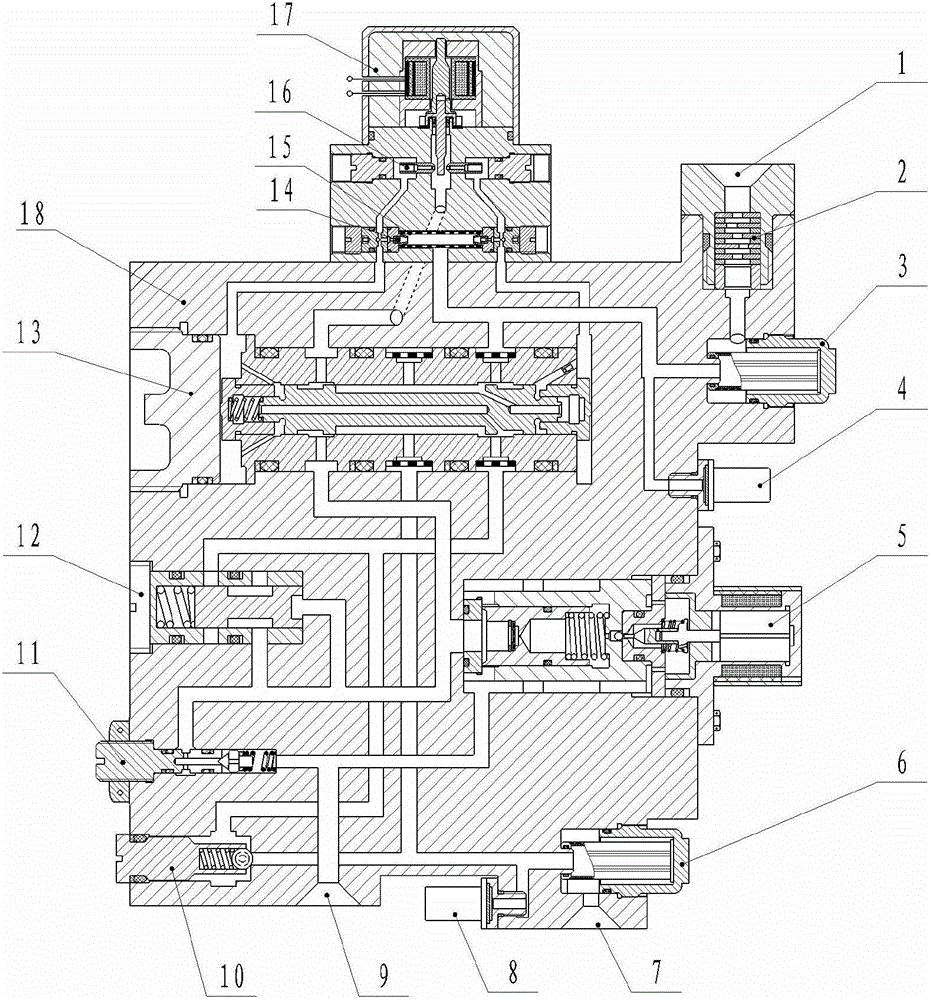

[0025] As shown in Figure 1. This embodiment is an electro-hydraulic pressure servo valve, which is obtained by improving and integrating the existing technology.

[0026] This embodiment includes an electro-hydraulic pressure servo valve oil inlet 1, a throttle 2, an inlet oil filter 3, an oil inlet pressure sensor 4, an oil return electromagnetic valve 5, a brake port oil filter 6, and an electro-hydraulic pressure servo valve brake port 7. Brake port pressure sensor 8, electro-hydraulic pressure servo valve oil return port 9, one-way valve 10, safety valve 11, hydraulic control valve 12, slide valve 13, and torque motor 17. Said components are integrated on the casing 18 and connected through corresponding oil passages.

[0027] The torque motor 17 adopts the prior art and is fixed on one side of the housing 18 . Both ends of the nozzle 16 in the torque motor communicate with the upper outlets of the throttle holes 14 at both ends of the torque motor oil filter through oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com