Novel plow discharger

A plough type unloader and a new type of technology, applied in the field of unloading devices, can solve the problems of unclean plough material and worn conveyor belt, and achieve the effect of improving conveying capacity, conveying stable and preventing material overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

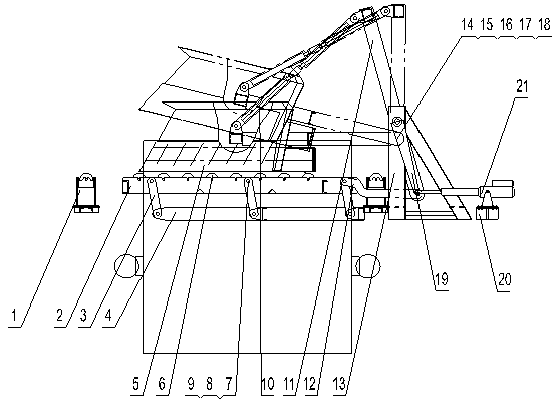

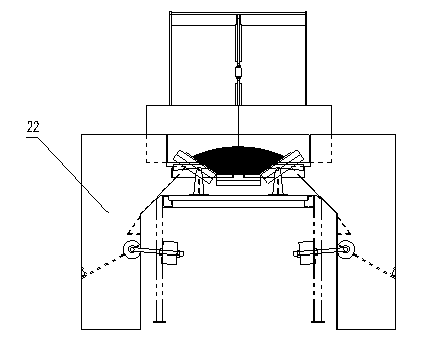

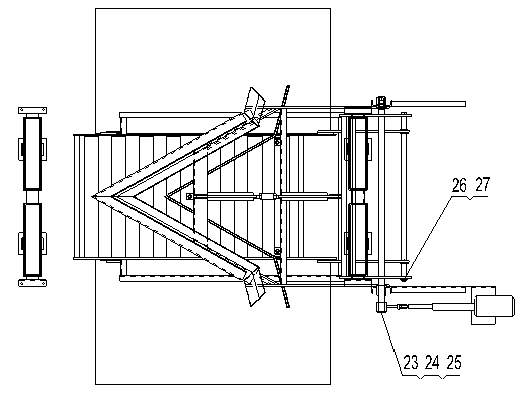

[0020] The present invention will be further described below in conjunction with the drawings:

[0021] A new type of plow unloader, as attached figure 1 , 2 , 3, used to unload the materials on the conveyor belt of the belt conveyor, including swing arm 11, electric push rod 21, plowshare 5, lifting frame 2; two conveyor belts fixed on the belt conveyor Two brackets 13 on the side, a swing shaft is connected between the two brackets 13 through a pin 14, a shim 15, a spring washer 16, a nut 17 and a split pin 18. In this embodiment, the two Two brackets 10 are welded to the middle frame of the belt conveyor as a whole. Each bracket 10 is fixed on the ground with an optical shaft 26 and a flat washer 27; both ends of the swing shaft are covered with a swing shaft that can be opposed to the swing shaft. For the rotating sleeve, the middle section of the swing arm is fixed on the sleeve, so as to form a connection with the swing shaft. Two swing arms 11 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com