Preparation method of thin-layer graphene oxide material

A technology of graphene and graphene microchips, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of difficult operation, long time consumption, and harsh preparation conditions, and achieve low cost, high yield, and reaction The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of graphene oxide

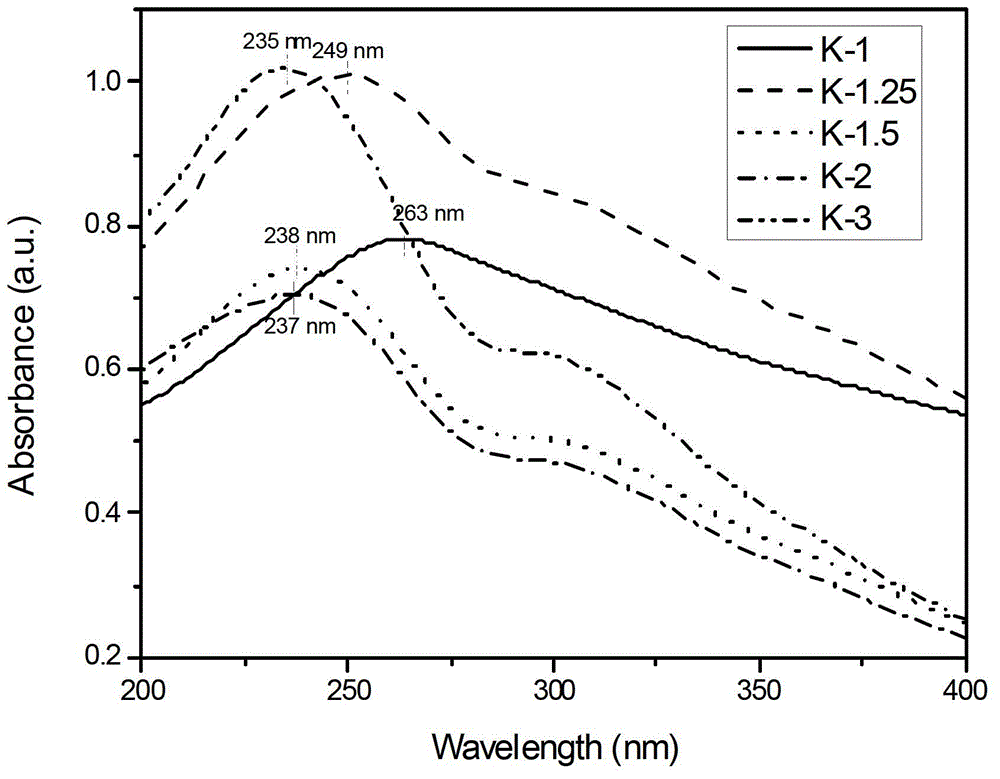

[0035] Take 0.2g of graphene microflakes and 10mL of concentrated sulfuric acid and mix uniformly at room temperature, then slowly add 0.6g of potassium permanganate in a room temperature water bath, then stir and react at room temperature for 2h, then add 5% HCl to remove unreacted Potassium permanganate, then washed to neutral with distilled water to obtain viscous graphene oxide, numbered K-3;

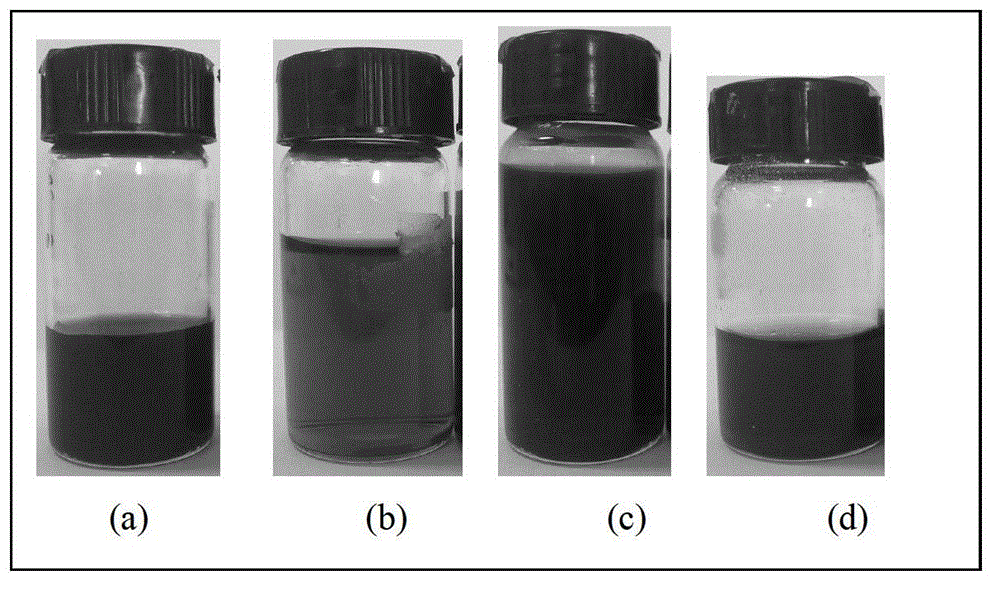

[0036] (2) Preparation of graphene oxide dispersion

[0037] Use a straw to absorb 1 mL of viscous graphene oxide, add it to 10 mL of distilled water or lye (pH=9), and sonicate at 500 W for 30 min to obtain a uniform and stable dispersion.

Embodiment 2

[0039] (1) Preparation of graphene oxide

[0040] Take 0.2g of graphene microflakes and 10mL of concentrated sulfuric acid and mix uniformly at room temperature, then slowly add 0.4g of potassium permanganate in a water bath at room temperature, then stir and react at room temperature for 2h, then add 5% HCl to remove unreacted Potassium permanganate, then washed to neutral with distilled water to obtain viscous graphene oxide, numbered K-2;

[0041] (2) Preparation of graphene oxide dispersion

[0042] Use a straw to absorb 1 mL of viscous graphene oxide, add it to 10 mL of distilled water or lye (pH=9), and sonicate at 500 W for 30 min to obtain a uniform and stable dispersion.

Embodiment 3

[0044] (1) Preparation of graphene oxide

[0045] Take 0.2g of graphene microflakes and 10mL of concentrated sulfuric acid and mix uniformly at room temperature, then slowly add 0.3g of potassium permanganate in a water bath at room temperature, then stir and react at room temperature for 2h, then add 5% HCl to remove unreacted Potassium permanganate, then washed to neutral with distilled water to obtain viscous graphene oxide, numbered K-1.5;

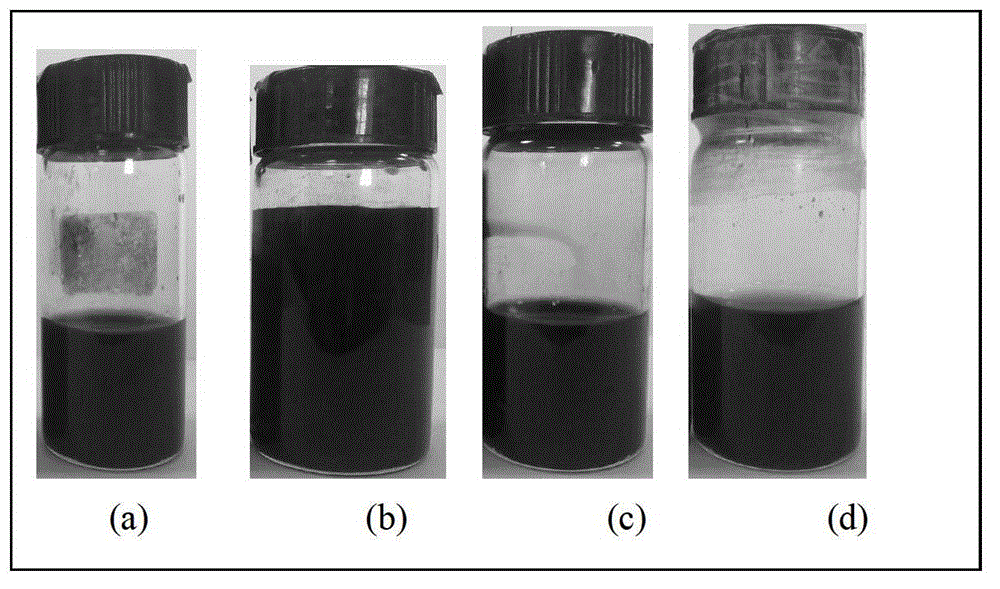

[0046] (2) Preparation of graphene oxide dispersion

[0047] Use a straw to absorb 1 mL of viscous graphene oxide, add it to 10 mL of distilled water or lye (pH=9), and sonicate at 500 W for 30 min to obtain a uniform and stable dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com