Method and special device for organic waste natural degradation

An organic waste and natural technology, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of mosquito breeding, waste of manpower, high energy consumption, etc., and achieve the effects of prolonging the degradation time, increasing equipment capacity, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

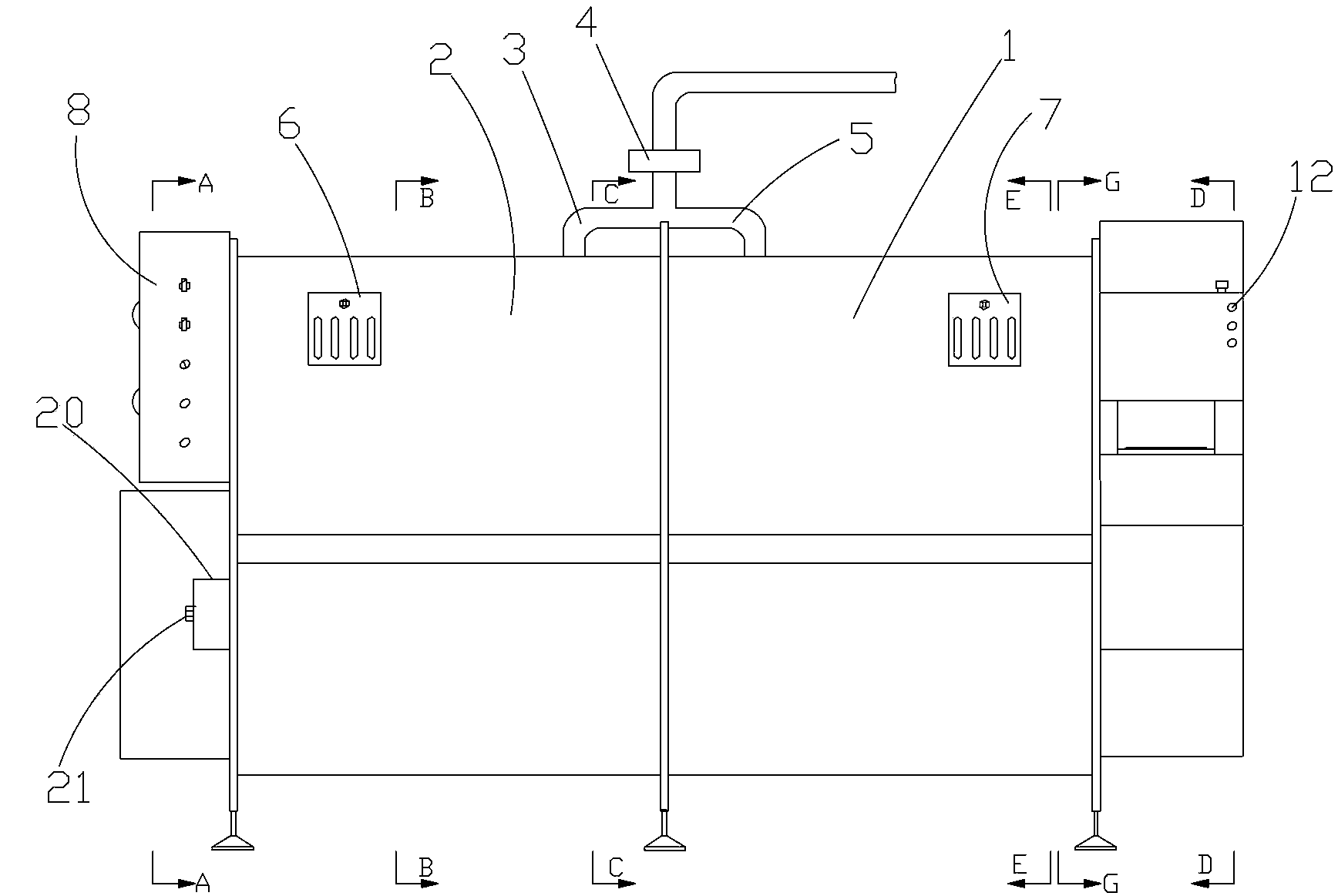

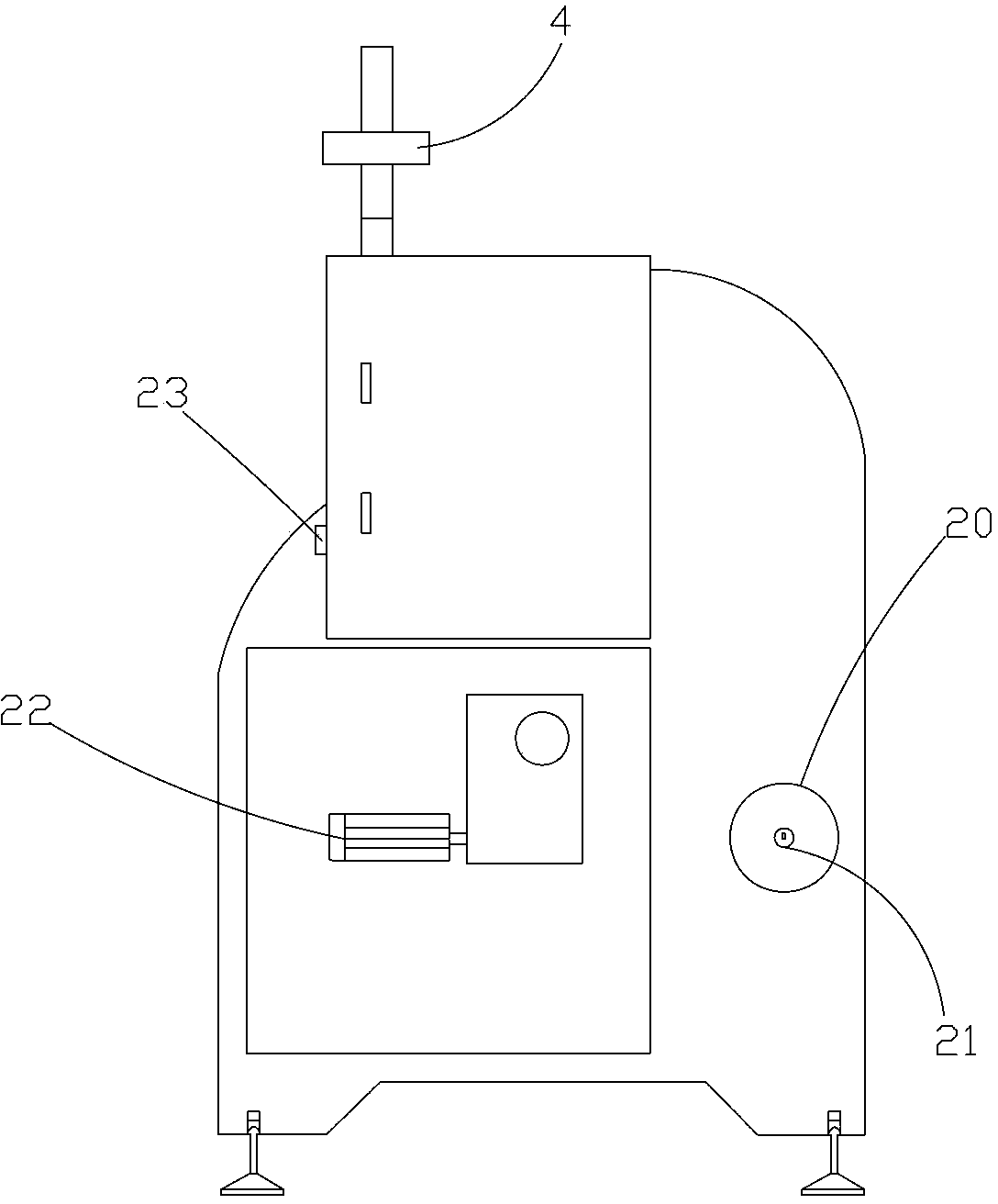

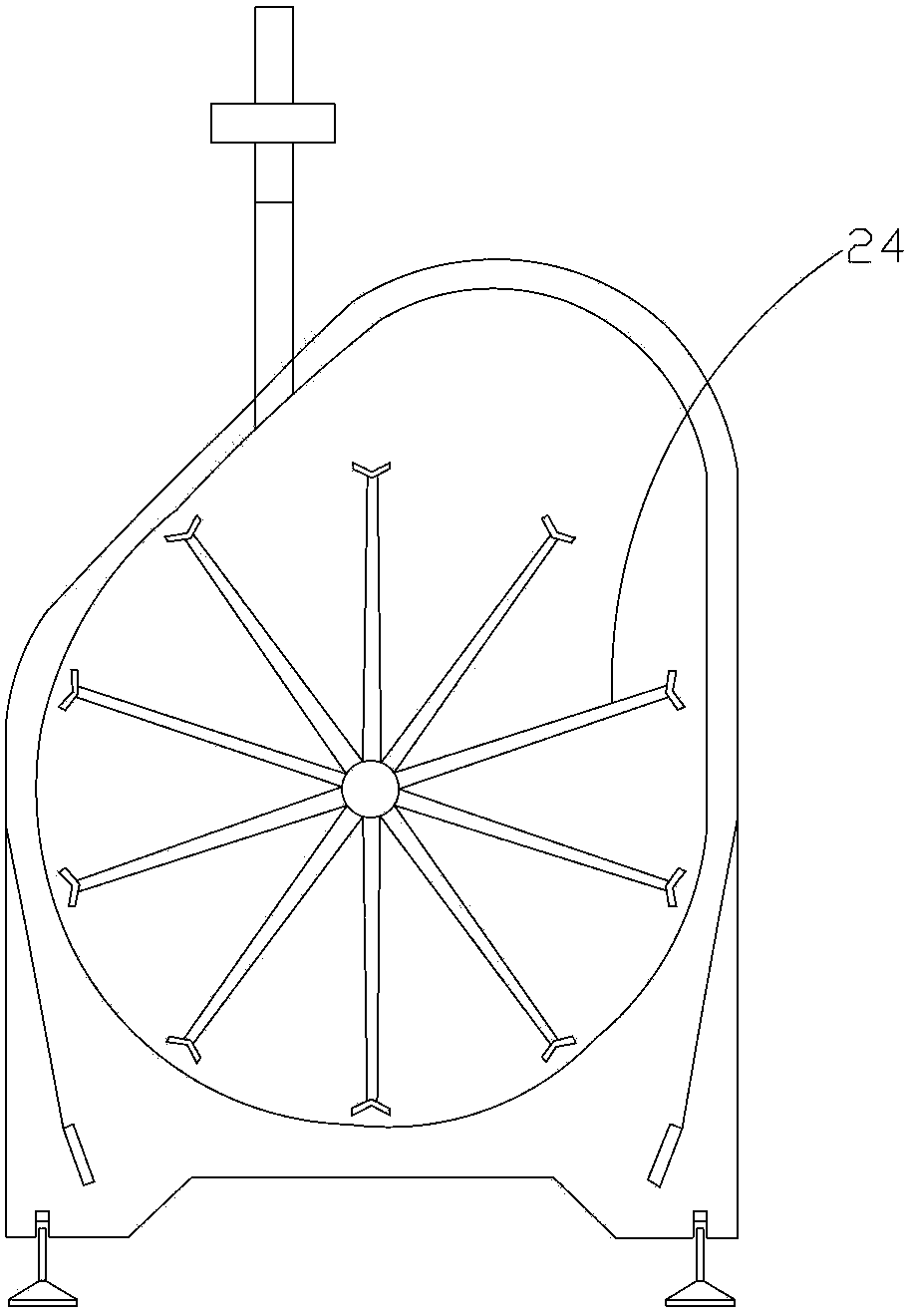

[0052] A natural degradation device for organic waste, such as Figure 1-8 As shown, it includes: a crushing device, a wood chaff storage device 9, a pre-degradation tank device 1, a late-stage maturation tank device 2 and a control system 8, wherein:

[0053] The crushing device is used to crush organic waste into granular state. The crushing device is provided with a feeding port for putting in organic waste. The feeding port is sealed by a feeding port sealing cover 14 so that the crushing device forms a sealed cavity. The feeding port sealing cover 14 is provided with an electromagnetic lock 15 that is used to sense the opening and closing of the feeding port. The electromagnetic lock 15 is electrically connected to the control system. A crushing device cutter 16 controlled by a crushing device motor 17 is installed in the sealed cavity. The crushing device cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com