Complex enzyme preparation for leaching tobacco material and enzyme leaching method

A technology of compound enzyme preparation and leaching method, which is applied in the fields of tobacco, tobacco treatment, tobacco preparation, etc. It can solve the problems of affecting the process operation, difficult to defibrate, and ineffective defibrillation of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

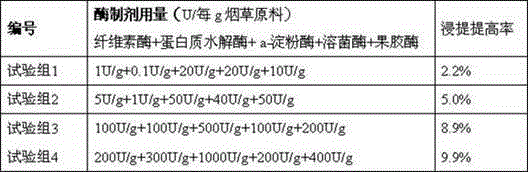

Examples

Embodiment 1

[0011] Compound enzyme preparation for extracting tobacco raw materials, containing 1000U of lysozyme, 0.1U of cellulase, 0.1U of α-amylase, 1000U of proteolytic enzyme and 0.1U of pectinase per 1 mg.

[0012] Extraction method: during extraction, the temperature is controlled at 30°C, and the liquid ratio is 1:5; add 1 mg of compound enzyme preparation per g of tobacco raw material, and stir for 4 hours; after solid-liquid separation, take the solid phase and add water to circulate and extract once according to the weight of the original solid.

Embodiment 2

[0014] Compound enzyme preparation for extracting tobacco raw materials, containing 200 U of lysozyme, 500 U of cellulase, 500 U of α-amylase, 0.1 U of proteolytic enzyme and 1000 U of pectinase per 1 mg.

[0015] The method of use is: control the temperature at 60°C during leaching, and the liquid ratio is 1:10; add 1 mg of compound enzyme preparation per g of tobacco raw material, and stir for 1 hour; after solid-liquid separation, take the solid phase according to the weight of the original solid and add water to circulate and extract twice.

Embodiment 3

[0017] Compound enzyme preparation for extracting tobacco raw materials, containing 0.1U of lysozyme, 1000U of cellulase, 1000U of α-amylase, 400U of proteolytic enzyme and 500U of pectinase per 1 mg.

[0018] The method of use is: during leaching, the temperature is controlled at 40°C, and the liquid ratio is 1:8; 1 mg of compound enzyme preparation is added to each g of tobacco raw material, and stirred for 1 to 3 hours; after solid-liquid separation, the solid phase is extracted according to the weight of the original solid, and then water is circulated for 2 Second-rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com