Device for manufacturing slag pellets through sulfuric-acid residue and manufacturing method thereof

A technology of slag pellets and sulfuric acid slag, which is applied in the field of metallurgy, can solve the problems that the sub-product pellets are not easy to completely burn, the pellets are easy to break, crush, and pollute the external working environment, so that it is not easy to burst and the quality of the finished product is good. , Improve yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

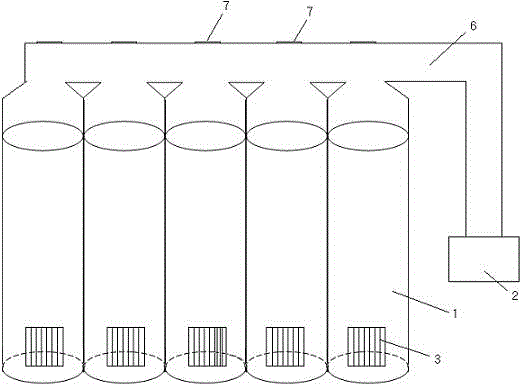

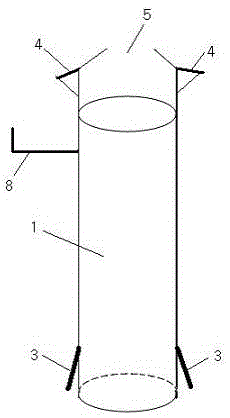

[0032] like Figure 1-Figure 2 As shown, a device for producing slag pellets from sulfuric acid slag provided by the embodiment of the present invention includes a combustion furnace, and is characterized in that: it also includes an exhaust fan 2;

[0033] The combustion furnace is provided with at least one furnace chamber 1, and each furnace chamber 1 of the combustion furnace is independent of each other, and the upper end of each furnace chamber 1 is provided with a feed port and an exhaust port 5, and is provided with a valve for closing the feed port. Feed bin door 4, the lower end of each furnace cavity 1 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com