Method for enhancing surface anti-fouling performance of stainless steel product

A stainless steel, anti-pollution technology, applied in the preparation of test samples, etc., can solve the problems affecting the measurement accuracy and residue of the instrument, achieve the effect of less pollutant residue, improve anti-pollution performance, and improve anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

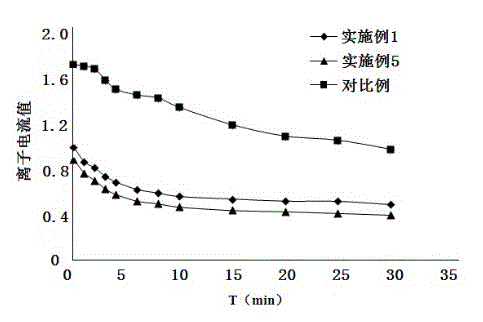

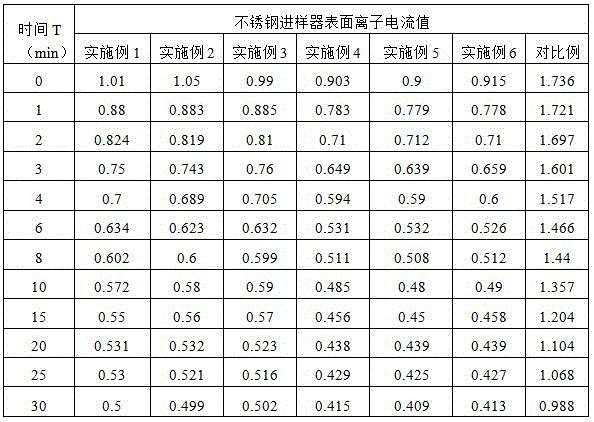

Image

Examples

Embodiment 1

[0027] The method for improving the anti-pollution performance of the surface of stainless steel products described in this embodiment includes:

[0028] (1) Use a metal cleaning agent to clean and wash the stainless steel products, then put the stainless steel products in 5% ammonium citrate solution, soak at 50°C for 60 minutes and then wash them with water;

[0029] (2) Heat the above water-washed stainless steel product to 80°C, keep it for 10 minutes, and then cool down to room temperature;

[0030] (3) Soak the above-mentioned treated stainless steel products in 20% nitric acid solution for 60 minutes at 10°C;

[0031] (4) Use deionized water to wash the stainless steel products after pickling and passivation, and then use compressed nitrogen to purge the stainless steel products for drying.

Embodiment 2

[0033] The method for improving the anti-pollution performance of the surface of stainless steel products described in this embodiment includes:

[0034] (1) Use a metal cleaning agent to clean and wash the stainless steel products, then put the stainless steel products in 8% ammonium citrate solution, soak at 55°C for 60 minutes and then wash them with water;

[0035] (2) Heat the above water-washed stainless steel product to 120°C, keep it for 30 minutes, and then cool it down to room temperature;

[0036] (3) Soak the above-mentioned stainless steel products in 35% nitric acid solution at 25°C for 60 minutes;

[0037] (4) Use deionized water to wash the stainless steel products after pickling and passivation, and then use compressed nitrogen to purge the stainless steel products for drying.

Embodiment 3

[0039] The method for improving the anti-pollution performance of the surface of stainless steel products described in this embodiment includes:

[0040] (1) Use a metal cleaning agent to clean and wash the stainless steel products, then put the stainless steel products in 10% ammonium citrate solution, soak at 70°C for 60 minutes, and then wash them with water;

[0041] (2) Heat the above water-washed stainless steel product to 100°C, keep it for 60 minutes, and then cool it down to room temperature;

[0042] (3) Soak the above-mentioned stainless steel products in 50% nitric acid solution at 30°C for 60 minutes;

[0043] (4) Use deionized water to wash the stainless steel products after pickling and passivation, and then use compressed nitrogen to purge the stainless steel products for drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com