Heating method and heating system for permanent magnet servo motor

A technology of permanent magnet servo motor and heating method, which is applied in the direction of control system, AC motor control, electrical components, etc., can solve the problem of lack of heating method, etc., and achieve the effect of avoiding multiple jumps and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

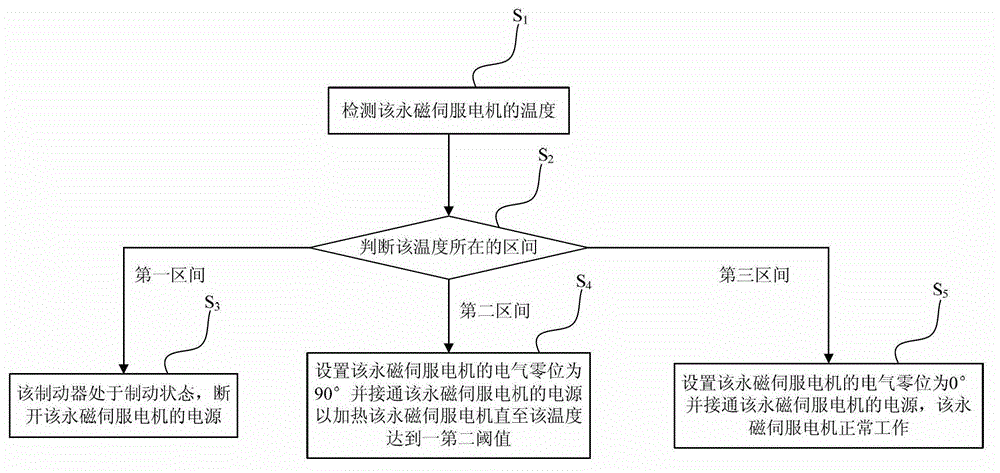

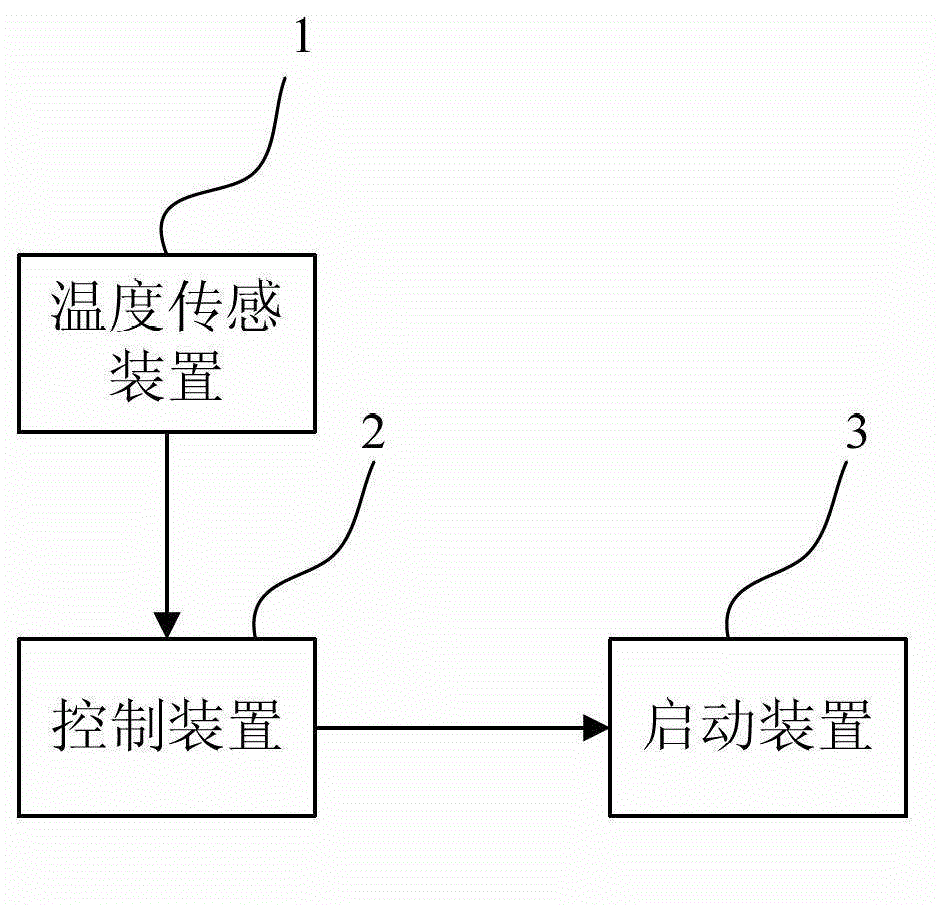

[0046] refer to figure 1 with figure 2 , to introduce the heating method and system of the permanent magnet servo motor according to an embodiment of the present invention.

[0047] The heating method of the permanent magnet servo motor comprises the following steps:

[0048] Step S 1 , detecting the temperature of the permanent magnet servo motor;

[0049] Step S 2 1. Determine the interval where the temperature is located. If the temperature falls into a first interval, enter step S 3 ; If the temperature falls into a second interval, enter step S 4 ; If the temperature falls into a third interval, enter step S 5 ;

[0050] Step S 3 , the brake is in the braking state, disconnect the power supply of the permanent magnet servo motor, and return to step S 1 ;

[0051] Step S 4 , setting the electrical zero positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com