Alumina crust block crushing process and production line thereof

A technology of crusted lumps and alumina, which is applied in the direction of grain processing, etc., can solve the problems of the previous sieve, the reduction of equipment operation rate, and the slow grinding speed of Raymond mill, so as to achieve the effect of purifying the environment without labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

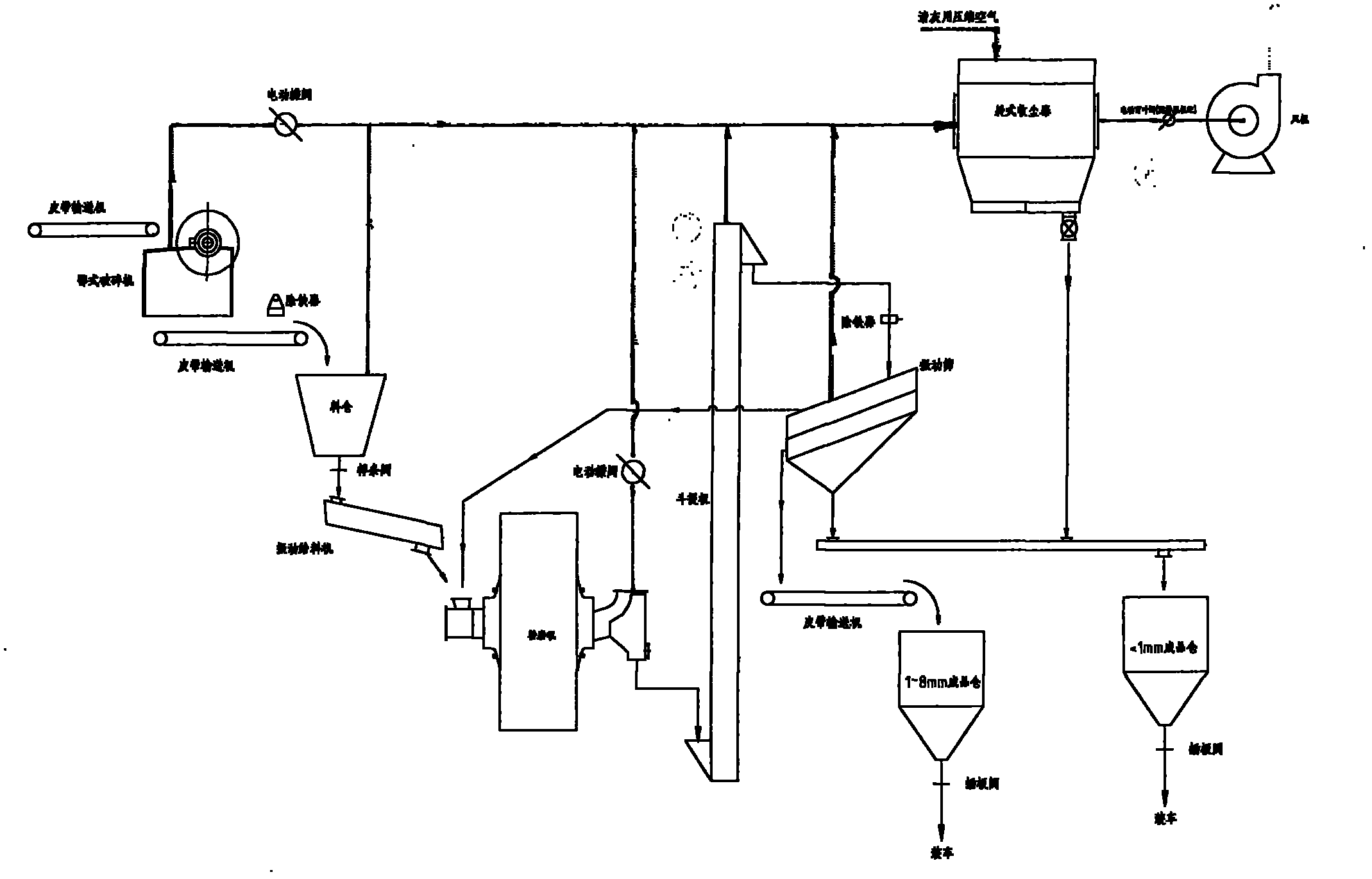

[0019] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a detailed implementation of the alumina crust block crushing process and its production line proposed in accordance with the present invention with reference to the accompanying drawings and preferred embodiments. The method, processing method, steps, characteristics and effects are described in detail later.

[0020] The present invention adopts the following technical scheme: a belt conveyor is used to transport large blocks of 300X300X300mm 3 Alumina crusted blocks of particle size are coarsely crushed by the jaw crusher, and the jaw crusher will produce a smaller particle size of 50-150mm after coarse crushing. 3 The first-level crushed material enters the next-level belt conveyor and is transported to the silo. An iron remover is placed on the belt conveyor. The iron-containing material in the future material is removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com