Crest generator

A generator and wave crest technology, applied in the field of wave crest generators, can solve the problems of large volume of tin bath, increased oxidation area, and no guarantee of solder quality, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

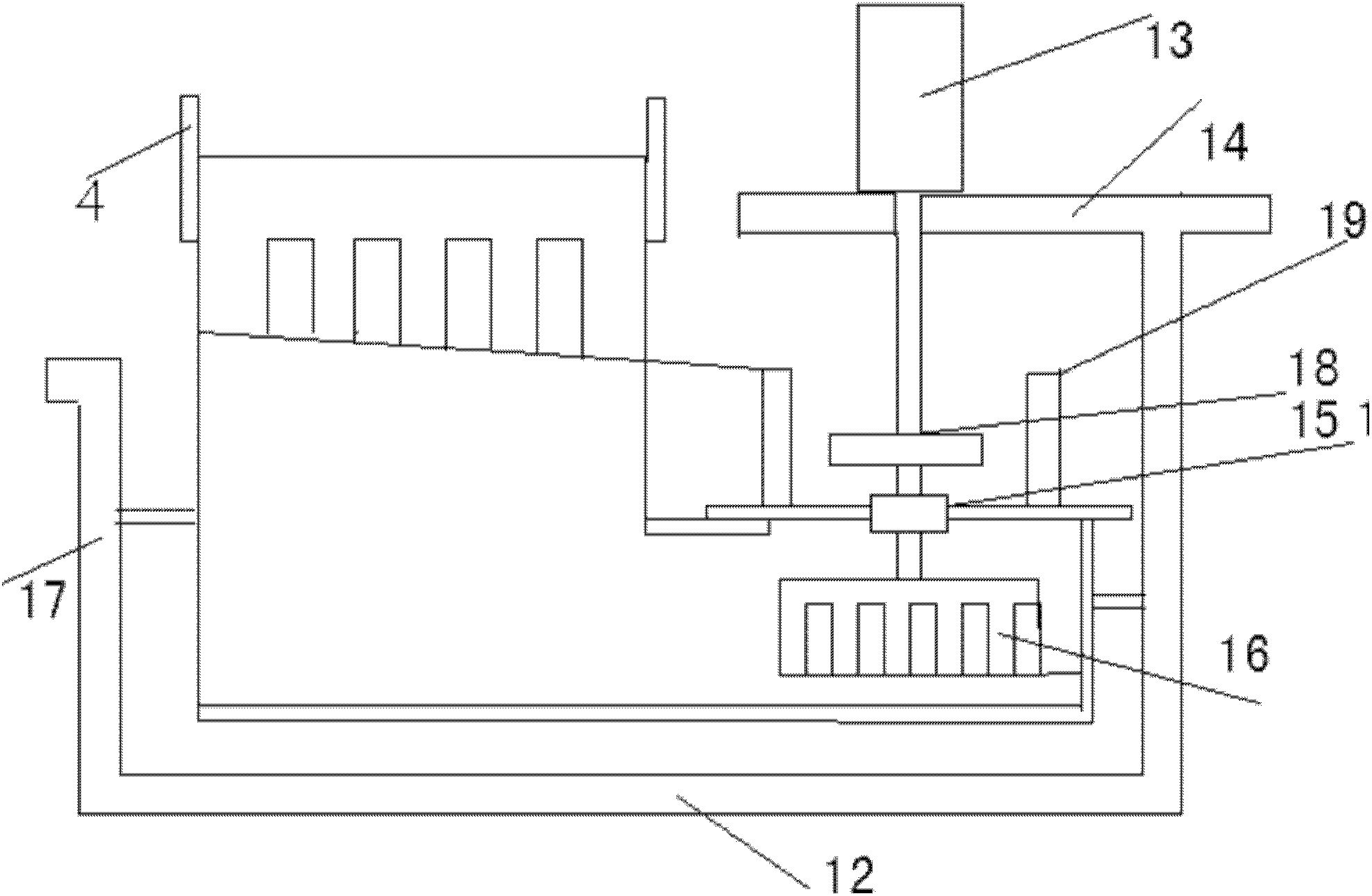

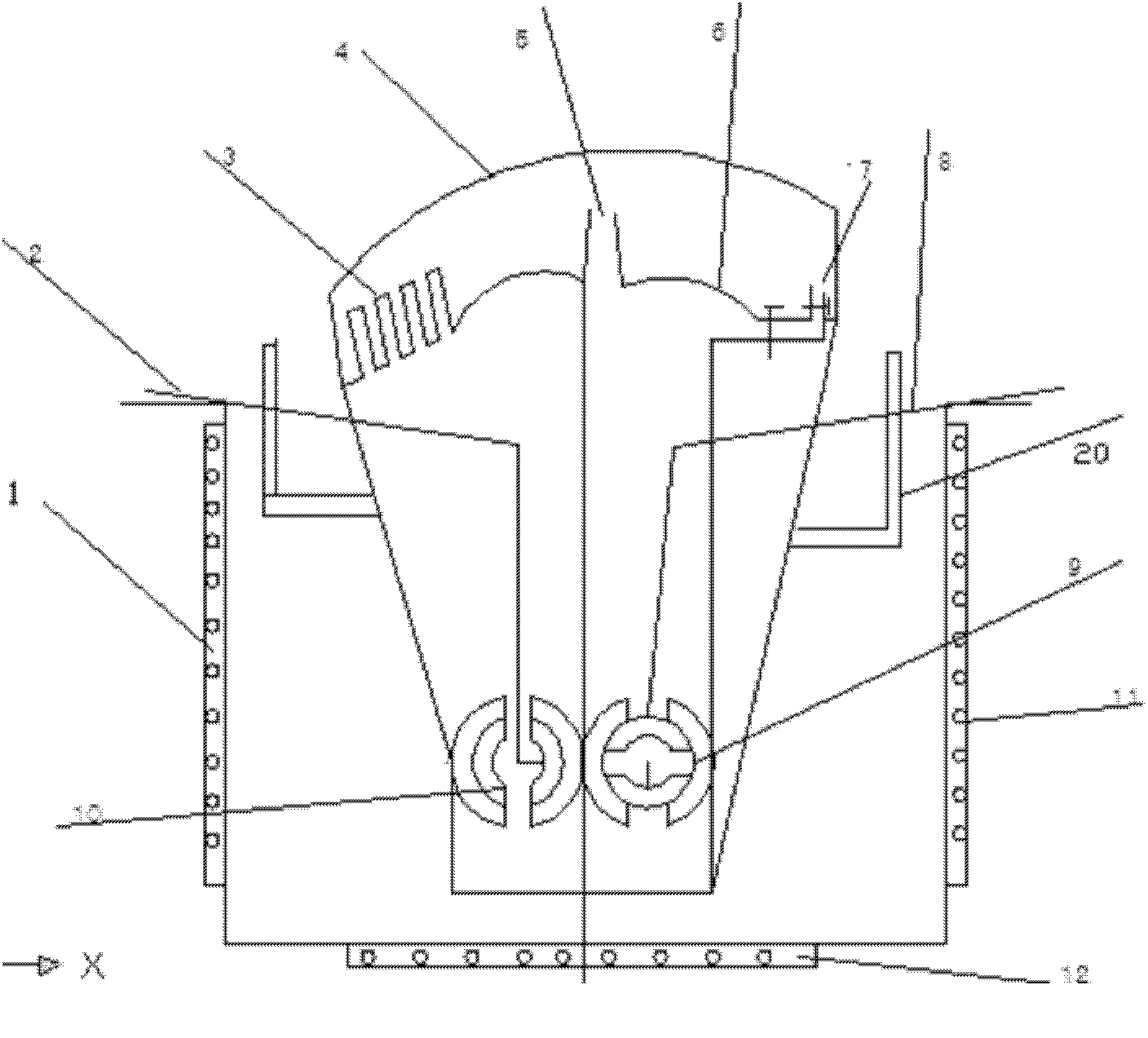

[0010] It is completed by the separator 18 welded on the vertical shaft. The reflow tank 20 and the separator shell 19 are mainly to ensure that the solder passes through the working area of the separator 18. The power mechanism pumps the tin flow into the wave crest liner, and the wave crest liner uses a middle interval The board is divided into two parts, which respectively provide solder for two peaks. The No. 1 regulating valve 10 regulates the first peak, which can be adjusted up or down or opened and closed arbitrarily as required; similarly, the No. 2 regulating valve 9 regulates the two peaks. It can also be adjusted up and down or opened and closed arbitrarily according to needs. The arrows in the figure show the direction of tin flow. The first crest spout 3 is a plurality of alternate tubular tin outlets. After the tin flow of one crest fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com