Novel ceramic heat insulating coat and preparation process thereof

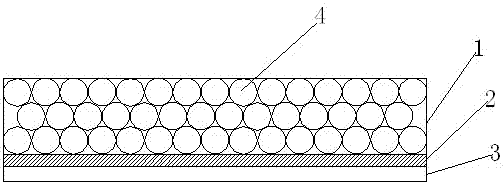

A technology of thermal insulation coating and thermal insulation layer, applied in layered products, metal layered products, reflective/signal coatings, etc., can solve the problem of increasing thermal expansion and thermal stress of linear materials, high surface temperature of objects, and accelerated material corrosion. and other problems, to achieve the effect of extending the heat transfer path, changing the direction of heat conduction, and overcoming the loose texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

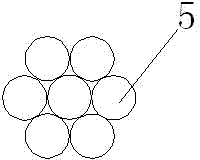

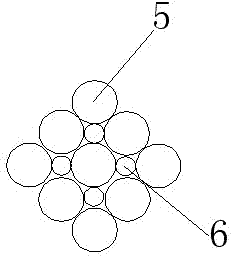

Method used

Image

Examples

Embodiment 1

[0046] The ceramic hollow microbeads in the ceramic heat-insulating coating of Example 1 The ceramic hollow microbeads in the matrix heat-insulating layer are made from the following raw materials in parts by weight in a vacuum environment: 26 parts of silicon dioxide; 43 parts of aluminum oxide; 4 parts of titanium dioxide; 8 parts of barium sulfate.

[0047] The manufacturing method of ceramic hollow microbead matrix heat insulation layer comprises the following steps:

[0048] 1) Add wetting agent, dispersant, antifreeze and other additives into water and stir to disperse for 20 minutes;

[0049] 2) Add pigments, fillers, and tetrafluoroethylene with a fluorine content of 30%-32% for stirring and dispersing. Add defoamers and thickeners during stirring. The stirring speed is 1000r / min, and the stirring time is 30min;

[0050] 3) Add the emulsion mixed evenly with additives and plasticizers and stir;

[0051] 4) Add the prepared ceramic hollow microspheres, add defoamer an...

Embodiment 2

[0056] The ceramic hollow microbeads in the ceramic heat-insulating coating of Example 2 The ceramic hollow microbeads in the matrix heat-insulating layer are made from the following raw materials in parts by weight in a vacuum environment: 28 parts of silicon dioxide; 42 parts of aluminum oxide; 4.5 parts of titanium dioxide; 7 parts of barium sulfate.

[0057] The manufacturing method of ceramic hollow microbead matrix heat insulation layer comprises the following steps:

[0058] 1) Add wetting agent, dispersant, antifreeze and other additives into water and stir to disperse for 20 minutes;

[0059] 2) Add pigments, fillers, and tetrafluoroethylene with a fluorine content of 30%-32% for stirring and dispersing. Add defoamers and thickeners during stirring. The stirring speed is 1100r / min, and the stirring time is 35min;

[0060] 3) Add the emulsion mixed evenly with additives and plasticizers and stir;

[0061] 4) Add the prepared ceramic hollow microspheres, add defoamer ...

Embodiment 3

[0066] The ceramic hollow microbeads in the ceramic heat-insulating coating of Example 3 The ceramic hollow microbeads in the matrix heat-insulating layer are made of the following raw materials in parts by weight in a vacuum environment: 30 parts of silicon dioxide; 40 parts of aluminum oxide; 5 parts of titanium dioxide; 6 parts of barium sulfate.

[0067] The manufacturing method of ceramic hollow microbead matrix heat insulation layer comprises the following steps:

[0068] 1) Add wetting agent, dispersant, antifreeze and other additives into water and stir to disperse for 20 minutes;

[0069] 2) Add pigments, fillers, and tetrafluoroethylene with a fluorine content of 30%-32% for stirring and dispersing. Add defoamers and thickeners during stirring. The stirring speed is 1200r / min, and the stirring time is 40min;

[0070] 3) Add the emulsion mixed evenly with additives and plasticizers and stir;

[0071] 4) Add the prepared ceramic hollow microspheres, add defoamer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com