Aerospace motor-driven helicopter

A helicopter and electric technology, applied in aircraft parts, power plant types, aircraft power transmission and other directions, can solve the problems of poor maneuverability, non-repeatable flight, complex energy consumption, etc., to achieve auxiliary uninterrupted driving, more conducive to manual control, increase The effect of wing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

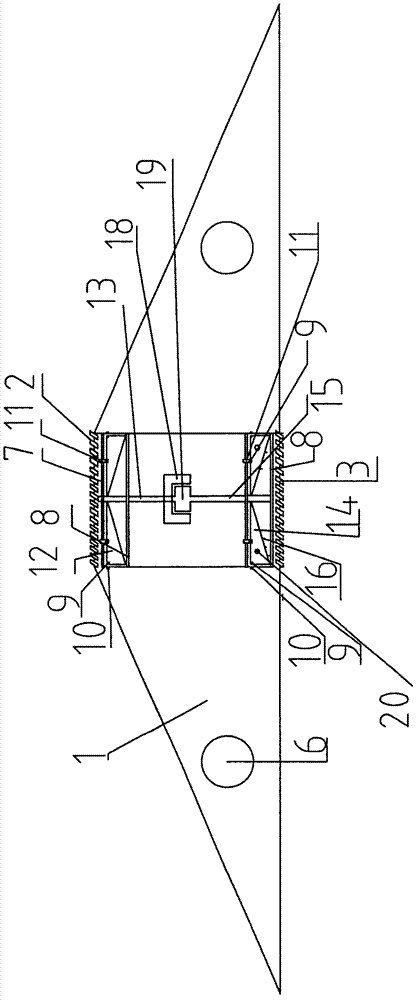

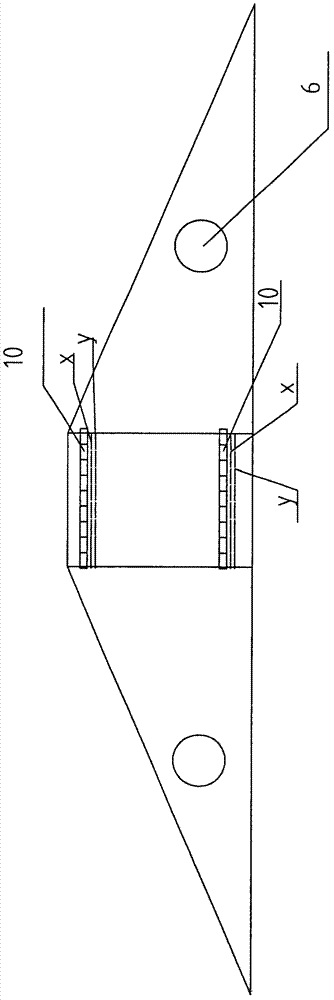

[0022] The auxiliary power of the present invention and embodiment 1 is: dish-shaped body, hollow column upper forward rotation screw propeller 12 and bottom reverse rotation screw propeller 14, the permanent magnet or electromagnet 9 of each wing top a little part and corresponding hollow The electromagnet winding on the column wall, through the power supply contact ABBA and the hollow column wall receiving the electric contact strip XY, after the two groups are energized, the same pole repels the different poles and attracts each other to push forward. The principle is: the power passes through the wing to make the top of the wing slightly The magnet or electromagnet winding 9 produces constant magnetic poles, and then through the permanent magnet or the four power supply contacts ABBA with different positive and negative poles at the bottom of the electromagnet 9 and the corresponding two sets of electric receiving contacts independent of the electromagnet winding of the corr...

Embodiment 3

[0024] The auxiliary power of the present invention and embodiment 2 is: body hollow column internal propeller 12, fixed frame 7 above 14 is equipped with reinforcing ring 11, electromagnet winding 10 and electric contact bar XY are arranged below reinforcing ring 11, wing and There are permanent magnets or electromagnets 9 and power supply contacts ABBA at the corresponding places of the reinforcement ring, through which two groups of power supply contacts ABBA with different positive and negative poles are energized with the electric contact strips XY of the two sets of electromagnet windings on the reinforcement ring respectively. These two groups of electromagnet windings 10, energized variable magnetic pole and permanent magnet or the magnetic pole of electromagnet 9 are the same pole and different pole, produce thrust and suction to assist wing to push forward and increase the intensity of wing.

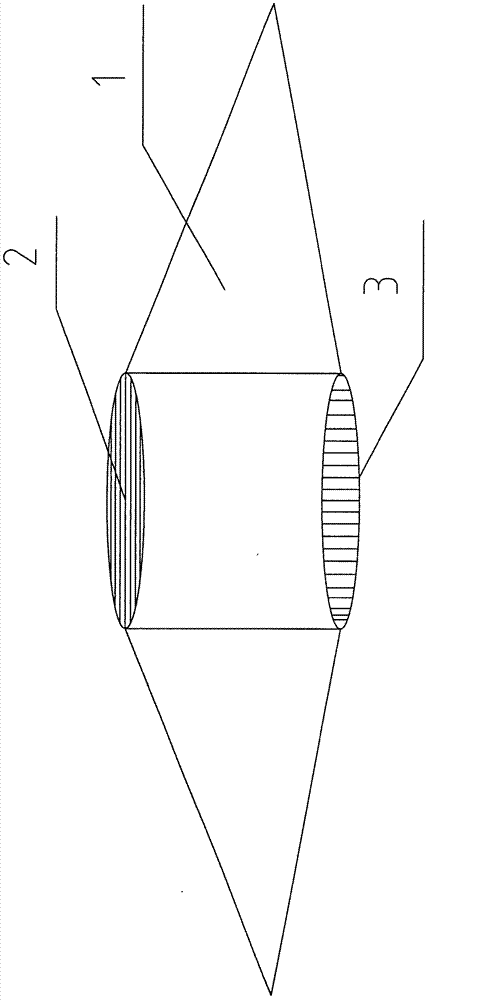

[0025] Embodiment 1 of the present invention, the power of the aerospace el...

Embodiment 5

[0027] Embodiment 1 of the present invention and the auxiliary power supply of the aerospace electric helicopter is that the lower end of the central shaft 15 of the upper forward-rotating propeller 12 in the hollow column of the body has a generator stator 18 that rotates forward together with it, and the rotor 19 is mounted on the lower propeller central shaft 15 The upper end of the rotor rotates in the opposite direction in the stator 18, and the generated current is transmitted to each wing circuit of the upper and lower propellers through the central shaft 15 to provide part of the power supply for the aircraft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com