Preparation method of calcium phosphate

A technology of calcium phosphate and calcium compounds, which is applied in the field of calcium phosphate, can solve problems such as unfavorable continuous chemical industry mass production, unfavorable mass production, and limited synthetic applications, so as to shorten the molecular diffusion distance, strengthen mixing kinetics, and ensure stable and reliable reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. The raw material solution of phase A is prepared by mixing 0.2M calcium nitrate and 1M triethanolamine solution;

[0061] 2. Preparation of phase B raw material solution, which is 0.12M disodium hydrogen phosphate solution;

[0062] 3. Adjust the back pressure of the closed system to 2.2MPa, and set the flow rate F of the phase A raw material liquid delivery pump A =75mL / min, the flow rate F of the phase B raw material liquid delivery pump B =75mL / min;

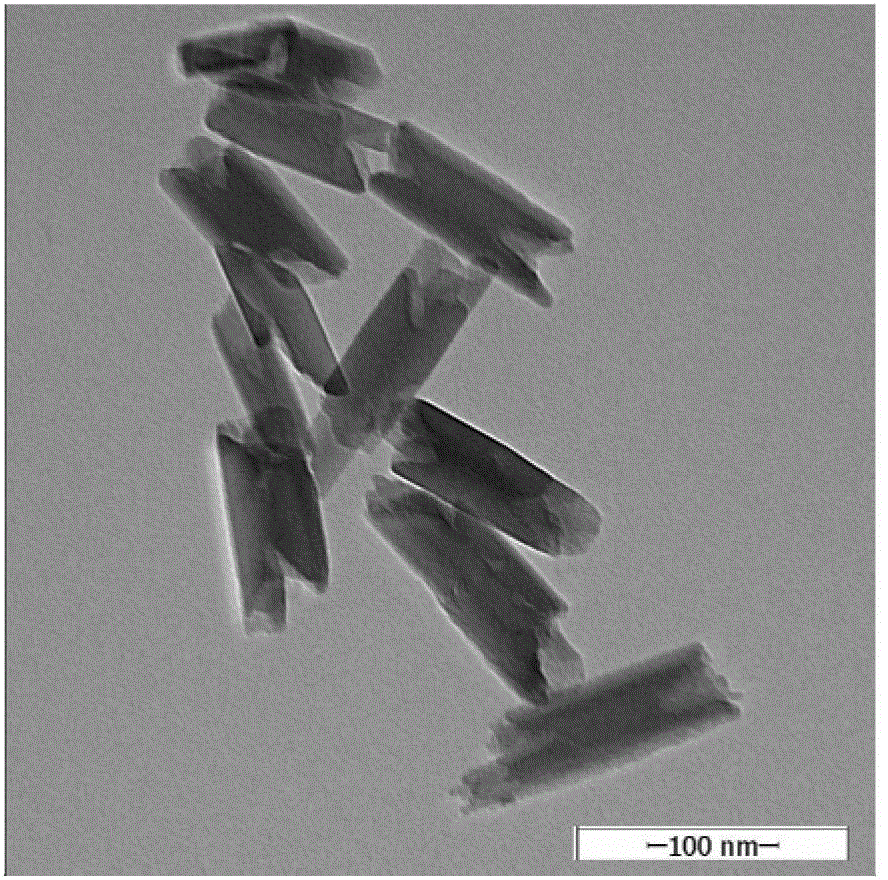

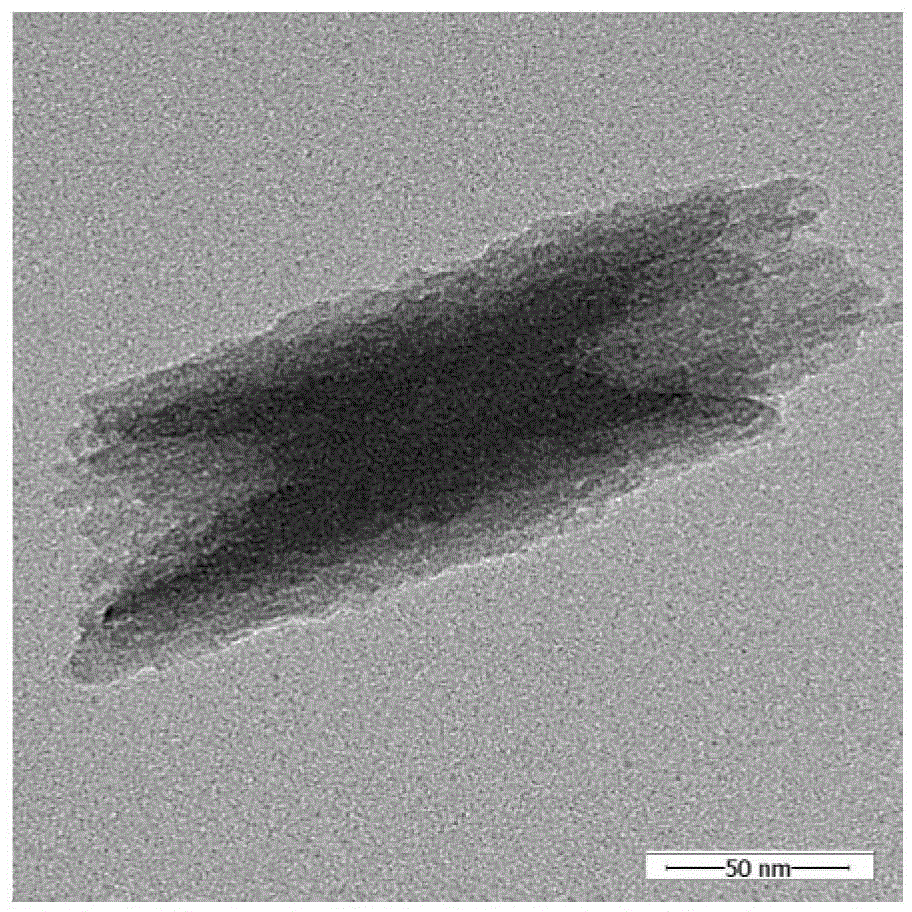

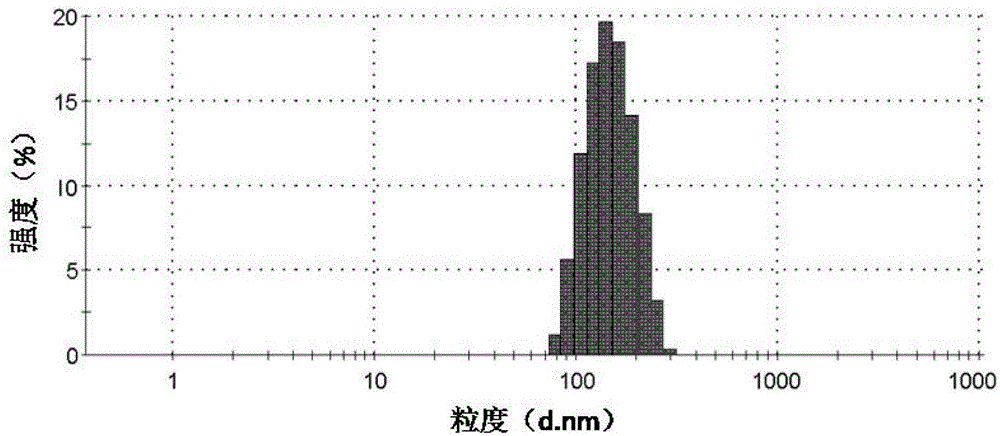

[0063] 4. Run the two-phase delivery pump to simultaneously transport the two-phase raw material liquid to the microchannel continuous mixing reactor with a channel size of 105 μm for uniform mixing reaction;

[0064] 5. Pass the mixed product through a rapid heating heat exchanger to make the system temperature reach 145°C;

[0065] 6. Enter the constant temperature of 145°C for 6s, and transport it to the rapid cooling heat exchanger to reduce the system temperature to 25°C;

[0066] 7. The cooled reaction prod...

Embodiment 2

[0070] 1. The raw material solution of phase A is prepared by mixing 0.2M calcium nitrate and 1M triethanolamine solution;

[0071] 2. Preparation of phase B raw material solution, which is 0.12M disodium hydrogen phosphate solution;

[0072] 3. Set the flow rate F of the phase A raw material liquid delivery pump A =75mL / min, the flow rate F of the phase B raw material liquid delivery pump B =75mL / min, at room temperature of 25°C under normal pressure, the two-phase raw material liquid is simultaneously transported to a microchannel continuous mixing reactor with a channel size of 105μm. Form calcium phosphate aggregate sol;

[0073] 4. Transport the mixed reaction product calcium phosphate aggregate sol to a washing and dehydrating device, wash twice with water and once with ethanol, and vacuum dry at 60°C to constant weight to obtain calcium phosphate powder.

[0074] The results of X-ray powder diffraction analysis are as follows: Figure 6 , is a typical diffuse peak o...

Embodiment 3

[0076] 1. The raw material solution of phase A is prepared by mixing 0.19M calcium nitrate and 1M triethanolamine solution;

[0077] 2. Preparation of phase B raw material solution, which is 0.12M disodium hydrogen phosphate solution;

[0078] 3. Adjust the back pressure of the closed system to 2.2MPa, and set the flow rate F of the phase A raw material liquid delivery pump A =75mL / min, the flow rate F of the phase B raw material liquid delivery pump B =75mL / min;

[0079] 4. Run the two-phase delivery pump to simultaneously transport the two-phase raw material liquid to the microchannel continuous mixing reactor with a channel size of 105 μm for uniform mixing reaction;

[0080] 5. Pass the mixed product through a rapid heating heat exchanger to make the system temperature reach 100°C;

[0081] 6. Enter the constant temperature of 100°C for 6s, and transport it to the rapid cooling heat exchanger to reduce the system temperature to 25°C;

[0082] 7. The cooled reaction produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com