Oxygen-separating and degradable thin plastic film

A technology of plastic film and degradable material, which is applied in the field of plastic film materials, can solve the problems of affecting the quality of packaging, lack of mechanical properties of film materials, poor oxygen barrier properties of films, etc. It is easy to implement in industrialization, realizes environmental friendliness and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

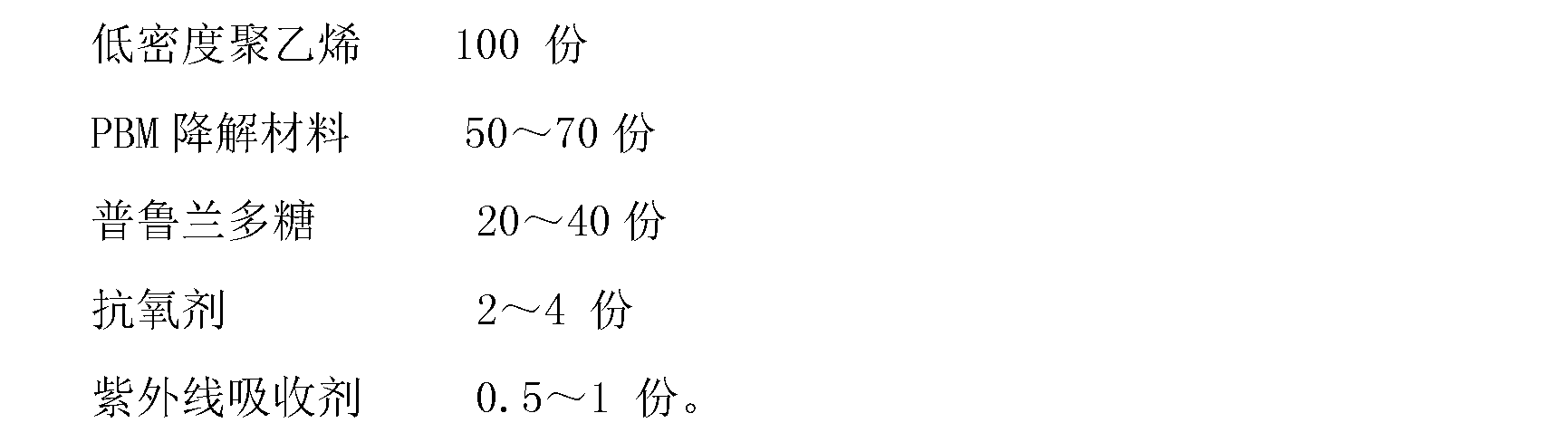

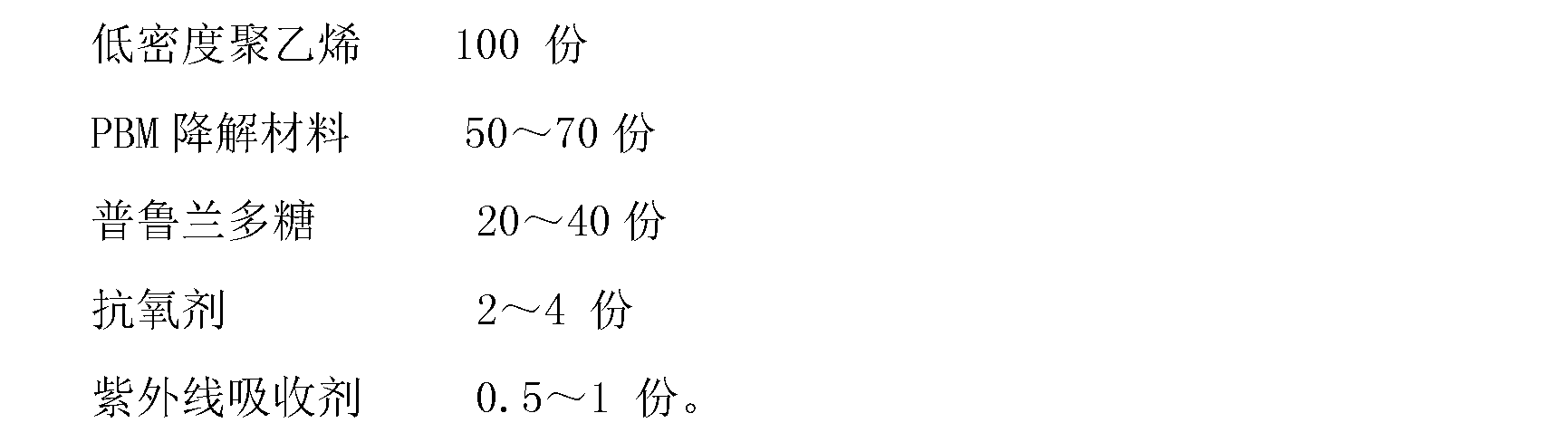

[0026] A kind of oxygen barrier and degradable plastic film, its preparation method comprises the following steps:

[0027] (1) Weigh LDPE, 100Kg; PBM degradation material, 50Kg; Pullulan polysaccharide, 40Kg; antioxidant 1010, 4 Kg; phenyl salicylate, 0.5Kg;

[0028] ⑵According to the step ⑴ formula, mix LDPE, Pullulan polysaccharide, antioxidant 1010, phenyl salicylate, etc. in a conventional high-speed mixer for 30 minutes, extrude and granulate in a twin-screw extruder to form a masterbatch; extrude The temperatures of the four sections in the back section of the granulator barrel are 180°C, 190°C, 190°C, and 200°C respectively, the temperatures in the four sections in the front section of the barrel are 200°C, 210°C, 210°C, and 230°C, and the temperatures in the two sections of the machine head are respectively 230°C, 230°C;

[0029] (3) Mix the masterbatch and PBM degradation material in step (2), extrude and blow the film by the plastic film blowing machine, the temper...

Embodiment 2

[0031] A kind of oxygen barrier and degradable plastic film, its preparation method comprises the following steps:

[0032] (1) Weigh LDPE, 100Kg; PBM degradation material, 70Kg; Pullulan, polysaccharide 40Kg; antioxidant 1010, 4 Kg; phenyl salicylate, 1Kg;

[0033] ⑵According to the step ⑴ formula, mix LDPE, Pullulan polysaccharide, antioxidant 1010, phenyl salicylate, etc. in a conventional high-speed mixer for 30 minutes, extrude and granulate in a twin-screw extruder to form a masterbatch; extrude The temperatures of the four sections in the back section of the granulator barrel are 180°C, 190°C, 190°C, and 200°C respectively, the temperatures in the four sections in the front section of the barrel are 200°C, 210°C, 210°C, and 230°C, and the temperatures in the two sections of the machine head are respectively 230°C, 230°C;

[0034](3) Mix the masterbatch and PBM degradation material in step (2), extrude and blow the film by the plastic film blowing machine, the temperatu...

Embodiment 3

[0036] A kind of oxygen barrier and degradable plastic film, its preparation method comprises the following steps:

[0037] (1) Weigh LDPE, 100Kg; PBM degradation material, 60Kg; Pullulan, polysaccharide 30Kg; antioxidant 1010, 3 Kg; phenyl salicylate, 1Kg;

[0038] ⑵According to the step ⑴ formula, mix LDPE, Pullulan polysaccharide, antioxidant 1010, phenyl salicylate, etc. in a conventional high-speed mixer for 25 minutes, extrude and granulate in a twin-screw extruder to form a masterbatch; extrude The temperatures of the four sections in the back section of the granulator barrel are 180°C, 190°C, 190°C, and 200°C respectively, the temperatures in the four sections in the front section of the barrel are 200°C, 210°C, 210°C, and 230°C, and the temperatures in the two sections of the machine head are respectively 230°C, 240°C;

[0039] (3) Mix the masterbatch and PBM degradation material in step (2), extrude and blow the film by the plastic film blowing machine, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com