Low-resistance tubular automatic sealing device

An automatic airtight and airtight device technology, which is applied in the direction of indoor sanitary pipeline installations, waterway systems, drainage structures, etc., can solve the problems of basement flooding, entry into the room, backflow, etc., and achieve minimum resistance loss, comfortable living environment, and indoor more air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

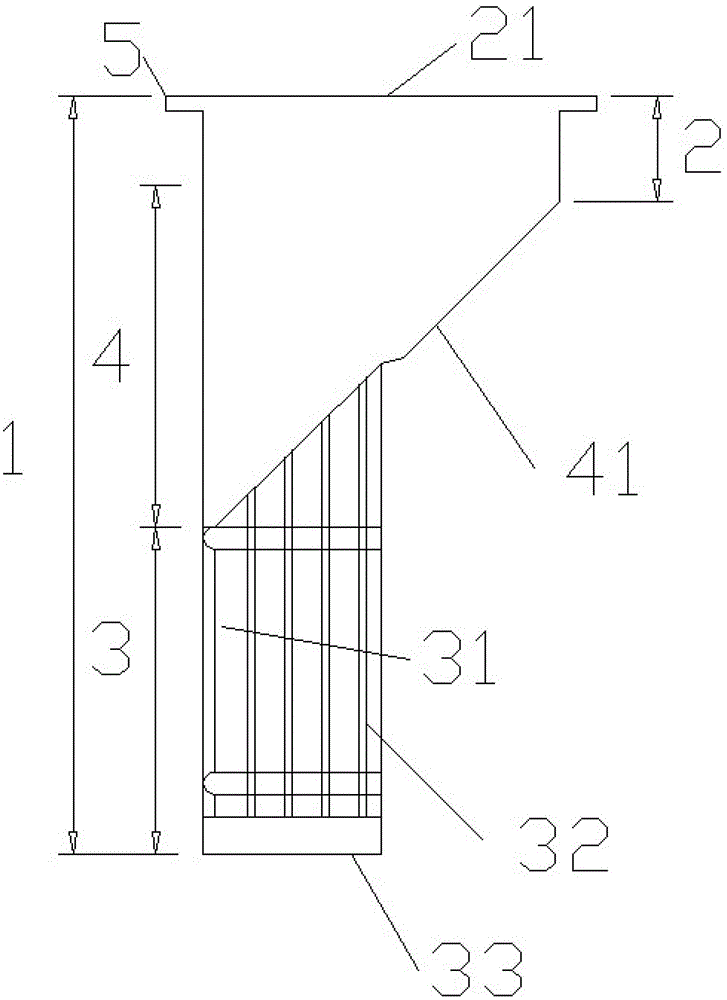

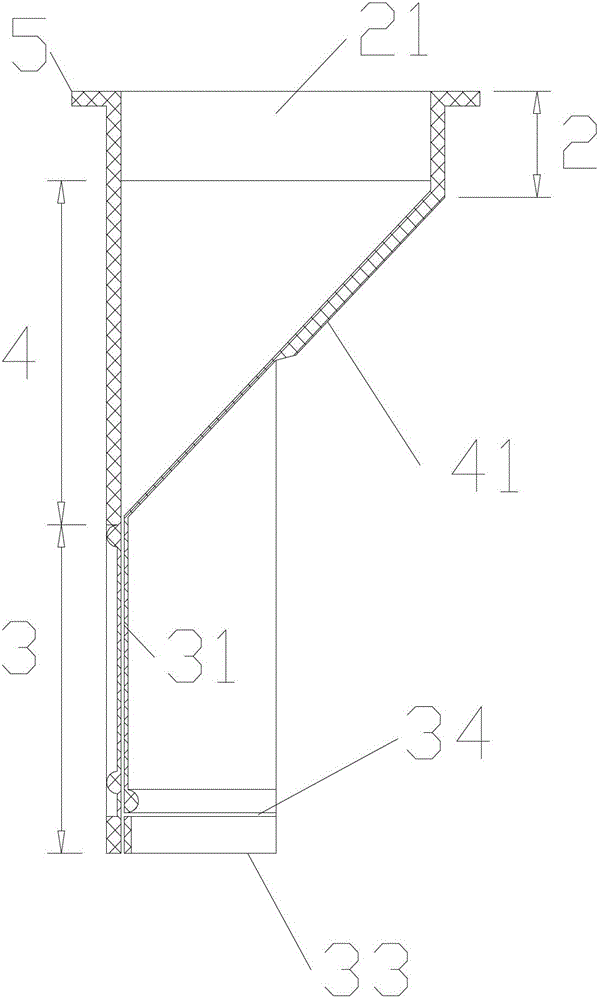

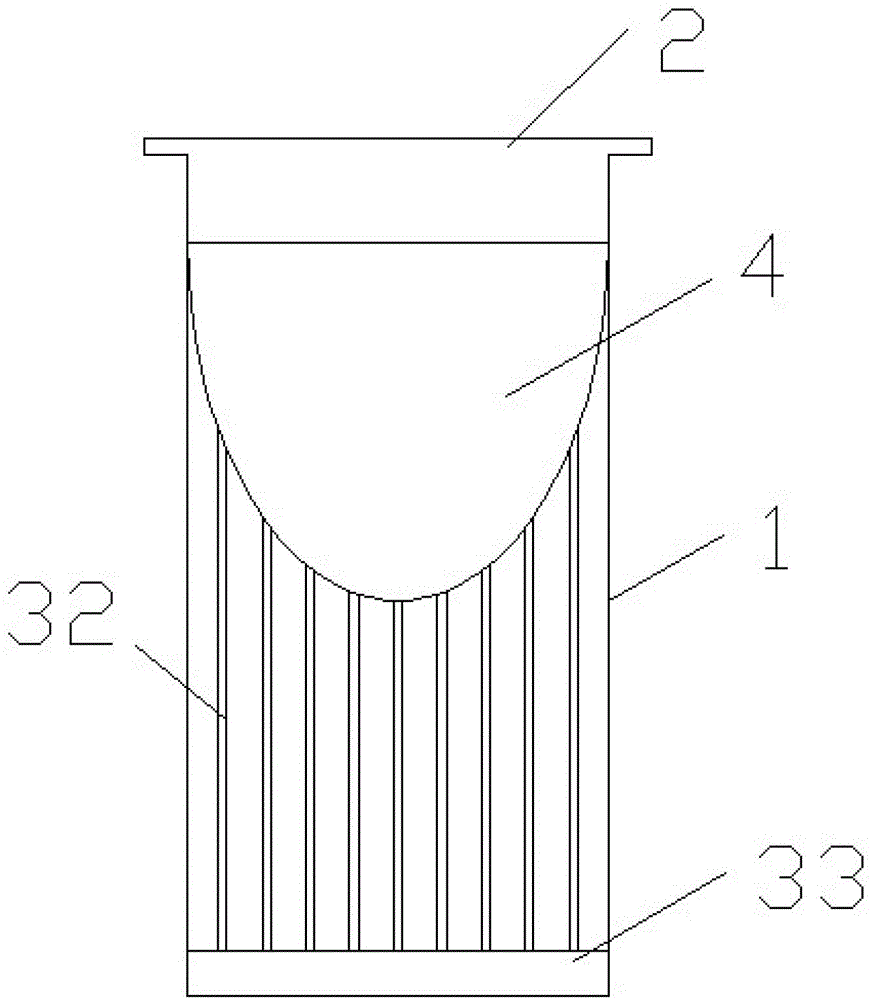

[0033] Such as Figure 1 to Figure 4 The illustrated embodiment, a low-resistance tube-type automatic sealer 1, includes an upper opening 2 and a lower opening 3, the inner wall of the lower opening 3 forms a lower opening 31, the lower opening 31 is a slit structure, the upper opening 2 and the lower opening The openings 3 are transitionally connected through the connecting portion 4 . In the first embodiment, the upper opening 21 formed on the inner wall of the upper opening 2 is a circular opening, and may also be a square or other open opening. The lower opening 31 in the first embodiment is in the form of a slit structure, preventing insects and rats from climbing into the airtight device through the lower opening, thereby entering the room.

[0034] The inner wall of the connecting portion 4 is provided with an inclined arc surface structure 41 . The arc surface structure 41 transition is used to make the opening of the sealing section easier when the fluid passes thro...

Embodiment 2

[0043] Such as Figure 5 The accumulated water discharge device 6 of the illustrated embodiment 2 includes an upper receiving pipe 61 and a lower receiving pipe 62 connected to the upper receiving pipe 61 , and the first embodiment is provided at the position of the accumulated water inlet 63 of the upper receiving pipe 61 . The low-resistance tube type automatic sealer 1 shown. The upper opening 21 of the low-resistance tube-type automatic sealer 1 is in communication with the accumulated water inlet 63. For other structures of the accumulated water discharger in Embodiment 2, refer to the prior art.

[0044] Embodiment 2 adopts the above structure, which can achieve the effects of pest prevention and pollution prevention, so as to make the living environment better and more hygienic; at the same time, it prevents the drainage riser from clogging and causing water accumulation, and returns to the room from the original water discharge device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com