recoil starter mechanism

A technology of starter and rotating shaft, applied in the direction of engine components, engine starting, machine/engine, etc., can solve problems such as safety problems and damaged parts, and achieve the effect of preventing damage and preventing the ratchet from immediately starting to swing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments will be described with reference to the drawings.

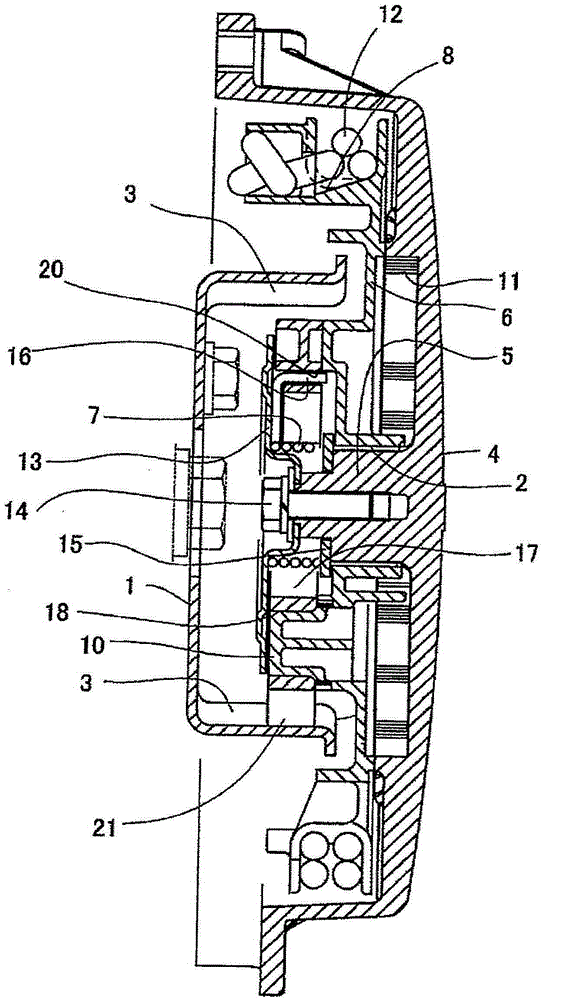

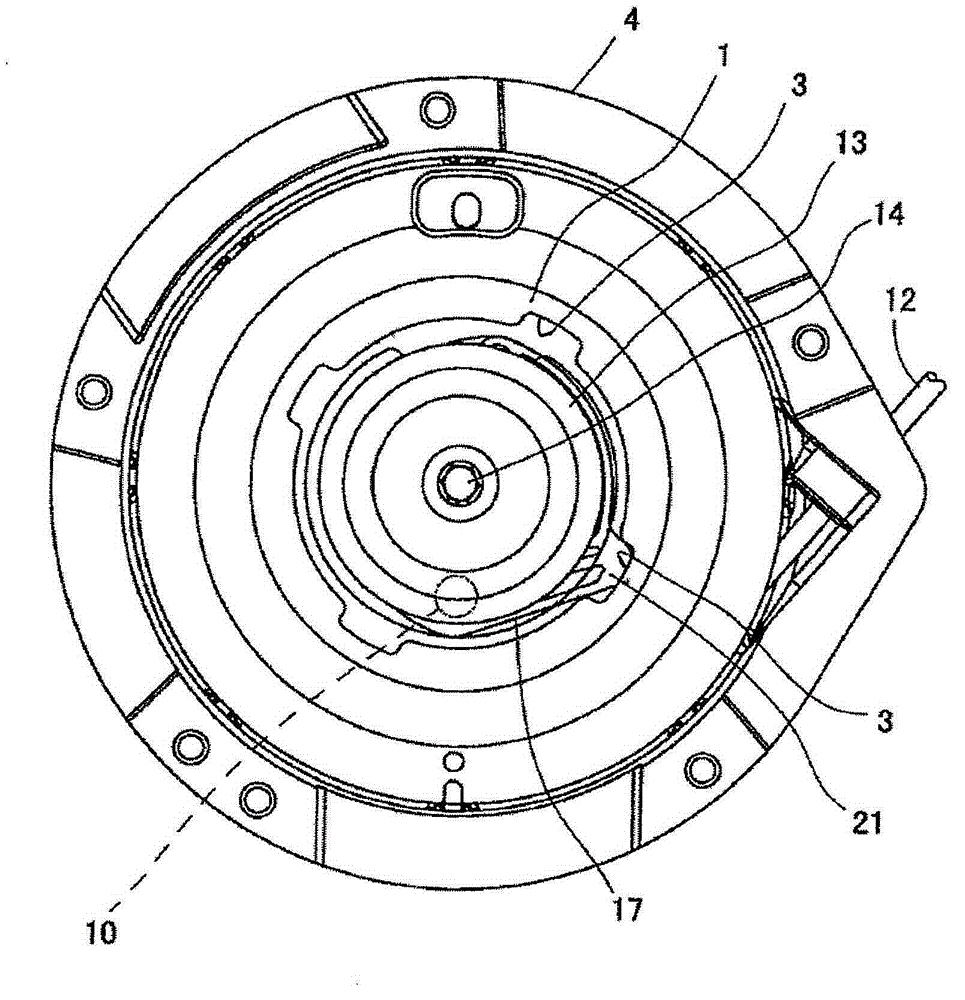

[0042] figure 1 Showing in section a recoil starter mechanism according to an embodiment, figure 2 The recoil starter mechanism is shown in operation from above, partly cut away.

[0043] The pulley 1 is directly coupled to, for example, the engine of a snowmobile. The engine and the pulley 1 rotate together with each other. The pulley 1 has a disk-like shape and includes a plurality of grooves (engagement portions) 3 formed in its inner peripheral surface. The rotation shaft 5 is provided inside the starter housing 4 and is provided at the center of the starter housing 4 . A rotatable rope drum 6 is rotatably mounted on the rotary shaft 5 , and a coil spring 7 is wound on the rotary shaft 5 .

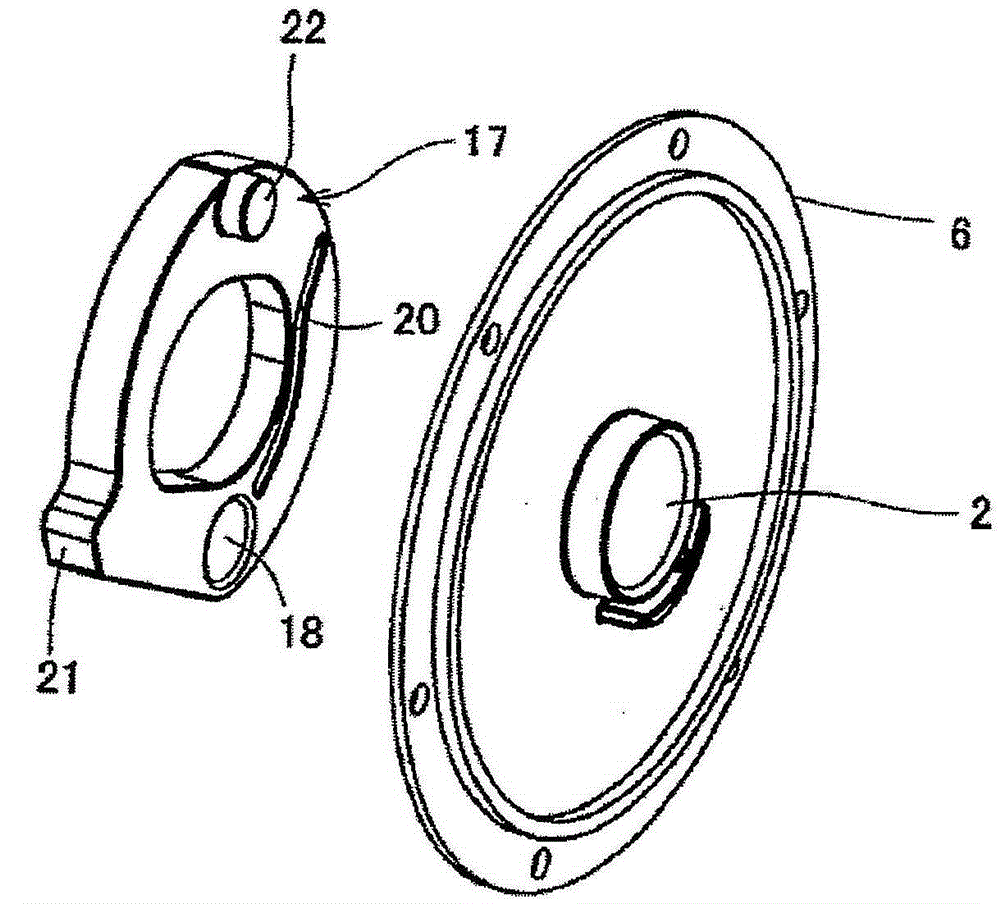

[0044] Such as Figures 1 to 4 As shown, the bearing hole 2 is formed in the rope drum 6 at a central portion of the rope drum 6 . The rope drum 6 includes: a rope winding groove 8 formed in an outer periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com