Magneto-rheological clutch transmission device

A clutch transmission, magnetorheological technology, applied in the direction of fluid clutch, clutch, mechanical equipment, etc., can solve the problems of optimal combination of difficult-to-separate devices, low degree of automation of devices, difficult product technology upgrade, etc., to solve the problems of mechanical friction loss and Fault defects, easy intelligent control, and the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

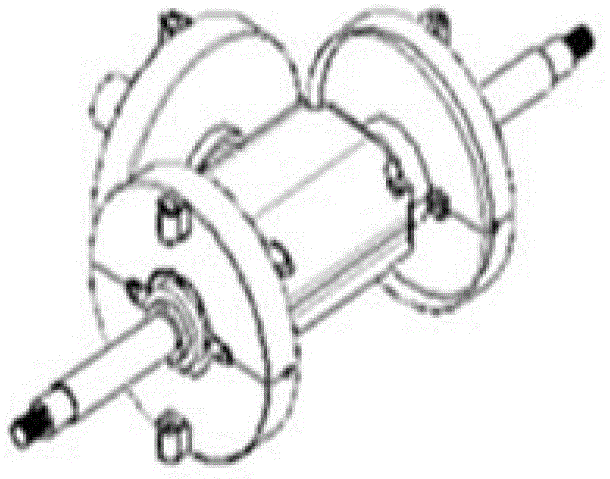

[0031] In the present invention, the clutch and the transmission functional mechanism are comprehensively designed into a power transmission assembly unit, and the magneto-rheological control technology is applied to the field of power transmission for the first time, which solves the problem of using magnetorheological fluid as the core medium of power transmission. The control method performs real-time control and management of the instantaneous, delayed clutch, and continuously variable speed functions required by the power load.

[0032] 1. Process procedure

[0033] 1. First prepare the parts and magnetorheological fluid materials produced according to the attached drawings.

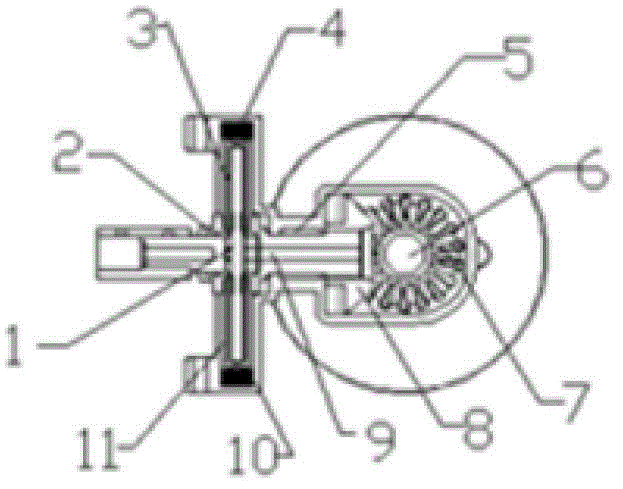

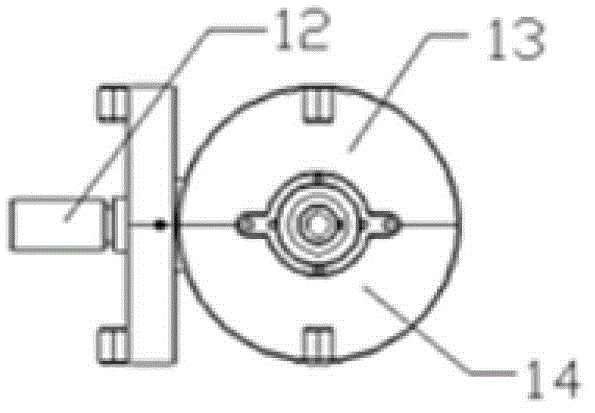

[0034] Concretely, comprise by coupling 12, clutch plate shaft 11, clutch frame shaft 9, clutch bearing 5, power gear, reversing gear 7, reversing shaft 6, reversing bearing form speed change commutator assembly; A magneto-rheological clutch assembly composed of a sheet shaft 1, a clutch housing br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com