parallel shift transmission

A technology of shifting transmission and transmission, applied in the field of drive train, can solve the problems of reduced transmission capacity, unsuitability for parallel shifting transmission, etc., and achieve the effect of increasing the total expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

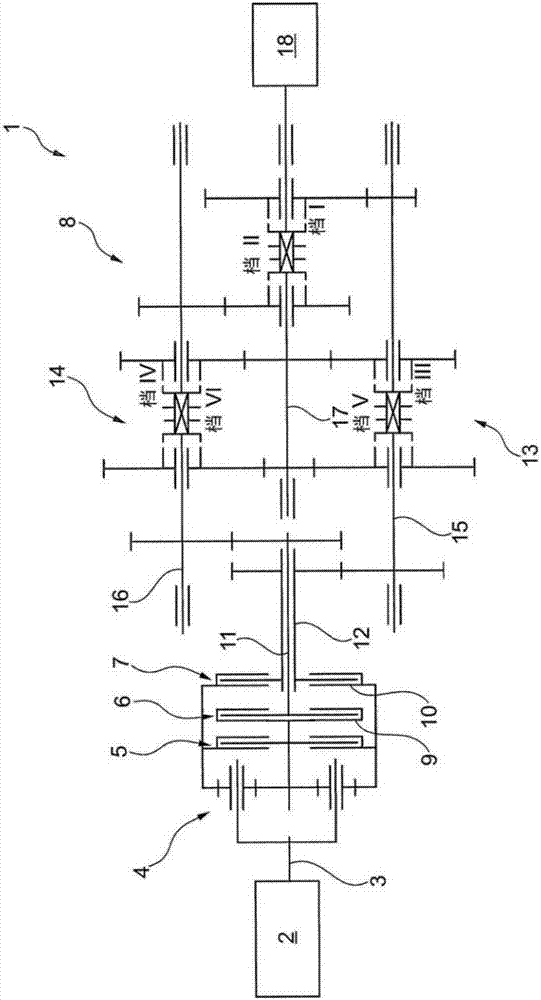

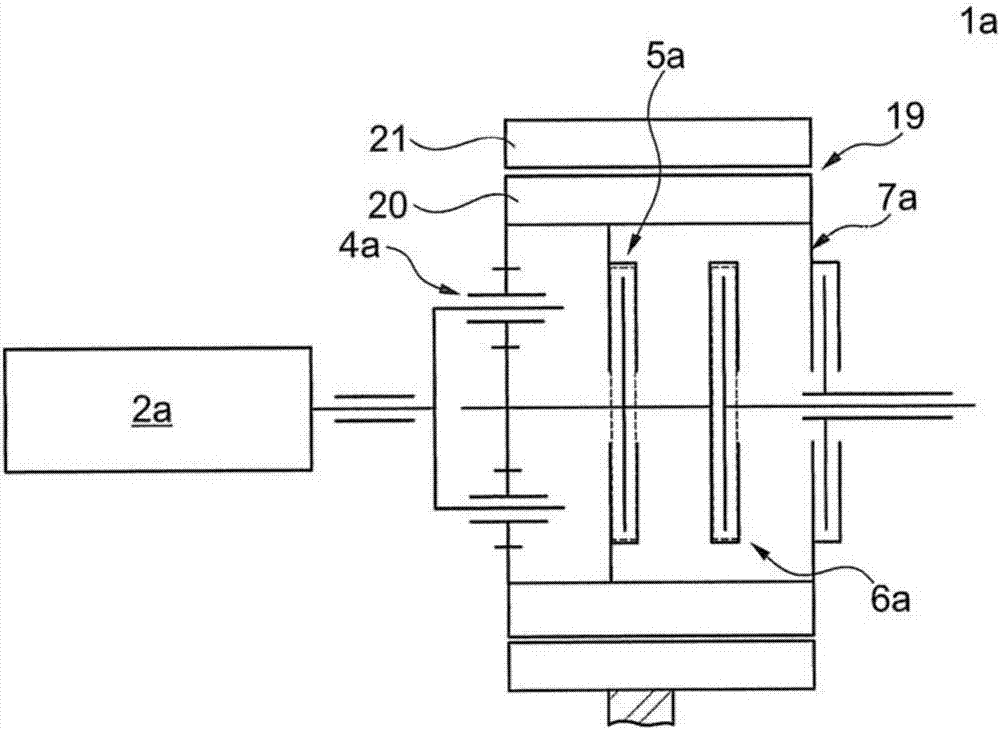

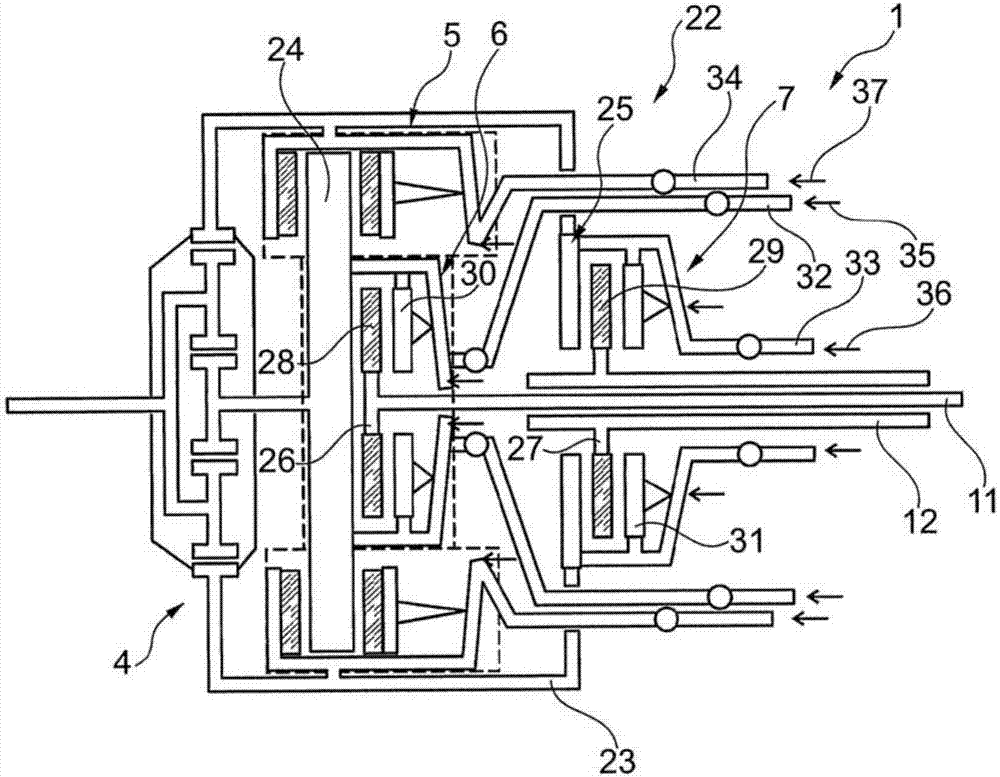

[0028] figure 1 A drive train 1 is shown schematically with: a drive unit 2 with a drive shaft 3, for example an internal combustion engine with a crankshaft; Includes files I to VI. The sum transmission 4 can be accommodated in the region of the engine compartment provided for the internal combustion engine, for example in a clutch housing.

[0029] The drive train 1 can be operated in three stable operating states of the friction clutches 6 , 7 and the lock-up clutch 5 . In these operating states, the torque on the sum transmission 4 is distributed corresponding to its gear ratio and the friction clutches 6 , 7 transmit a corresponding share to the associated transmission input shaft 11 , 12 . If a gear is inserted in both subtransmissions 13, 14, an intermediate gear is obtained. In the first operating state, the lock-up clutch 5 is open and the two friction clutches 6 , 7 are closed. In the second operating state, the locking clutch 5 is closed, the friction clutch 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com