Method and device for non-contact sealing between rotor and stator

A non-contact, stator technology used in engine sealing, leakage prevention, engine components, etc., can solve problems such as increased friction power and heat generation, and achieve the effects of minimum friction power, improved sealing effect, and low-cost structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

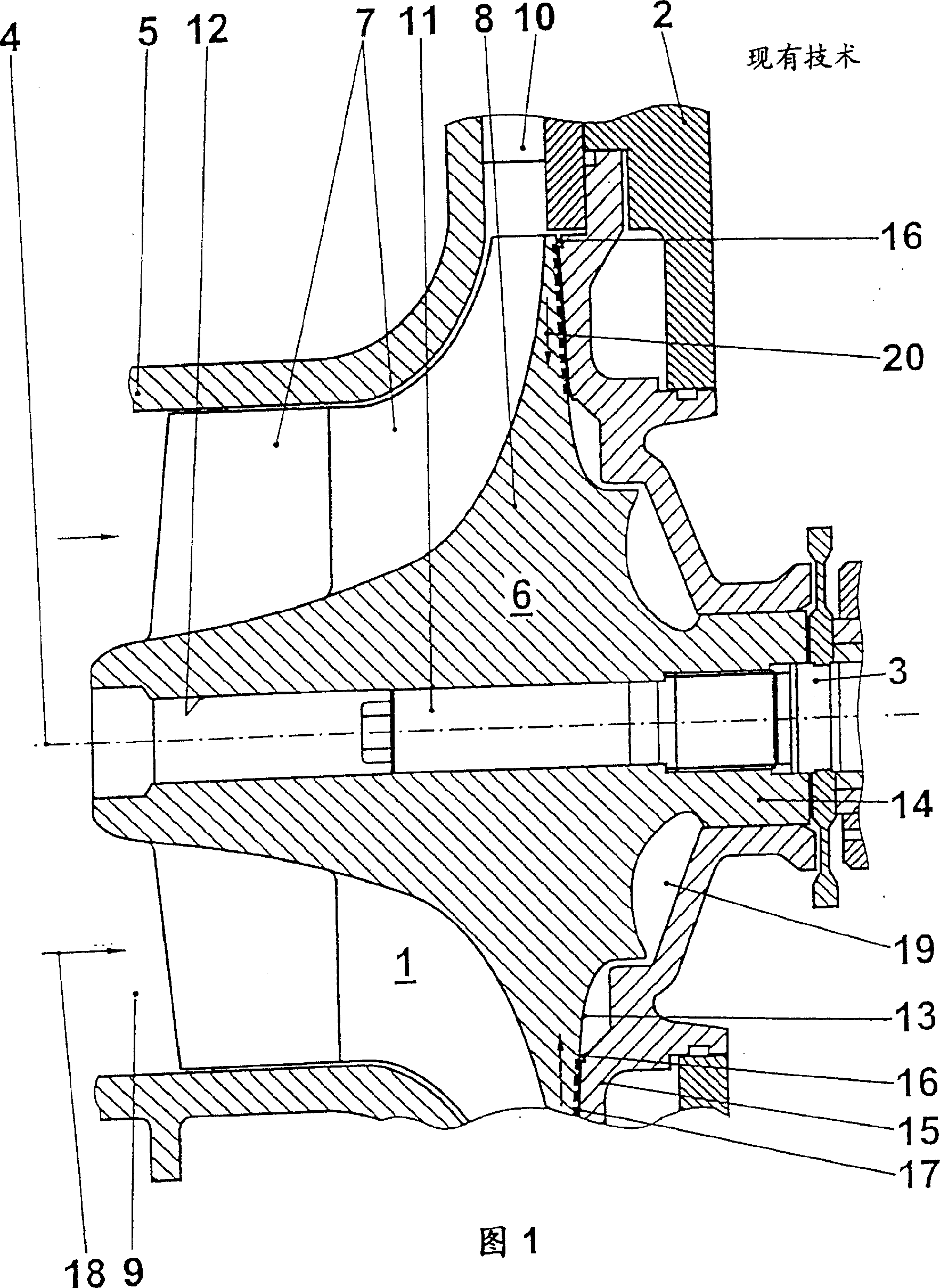

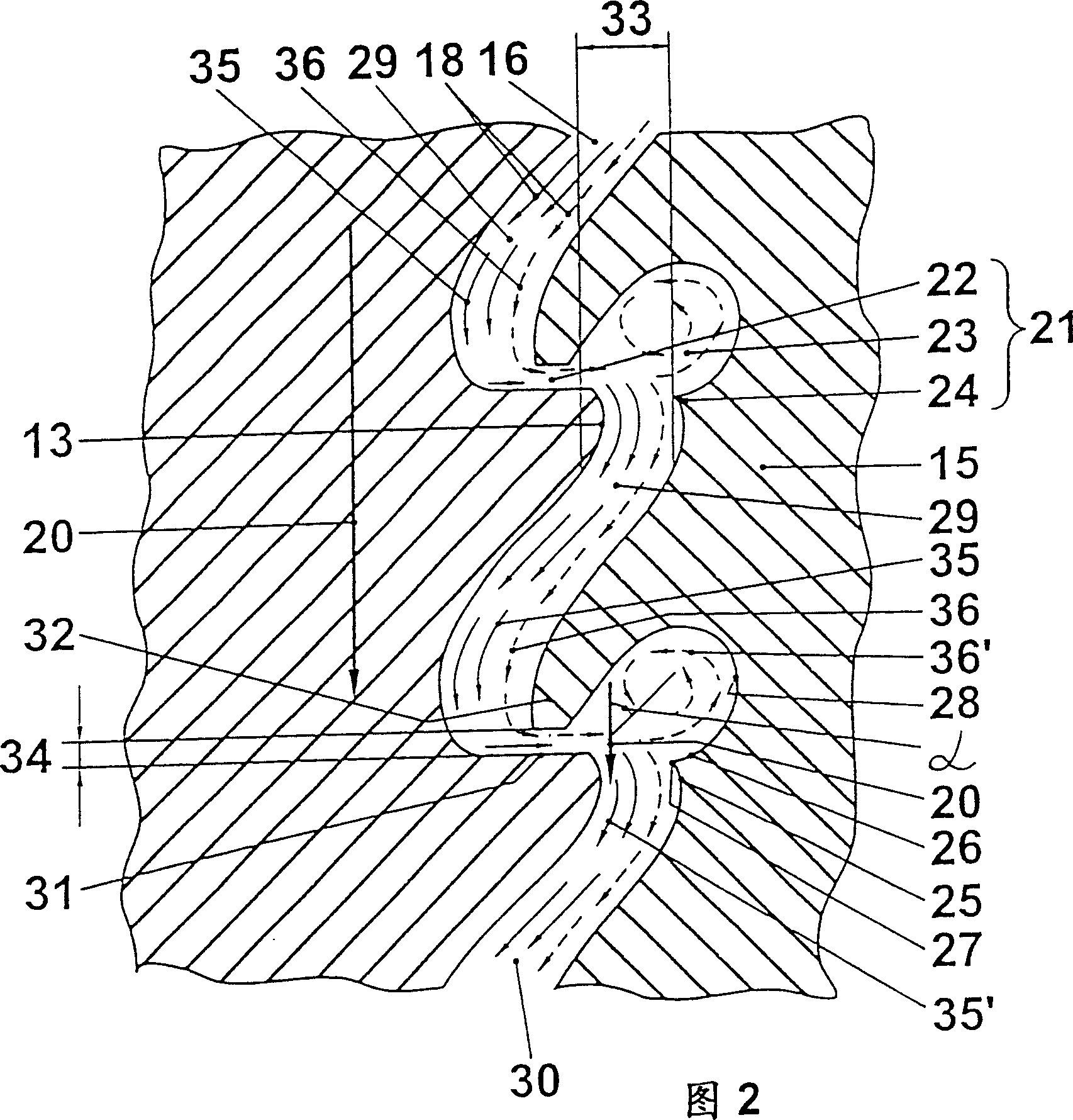

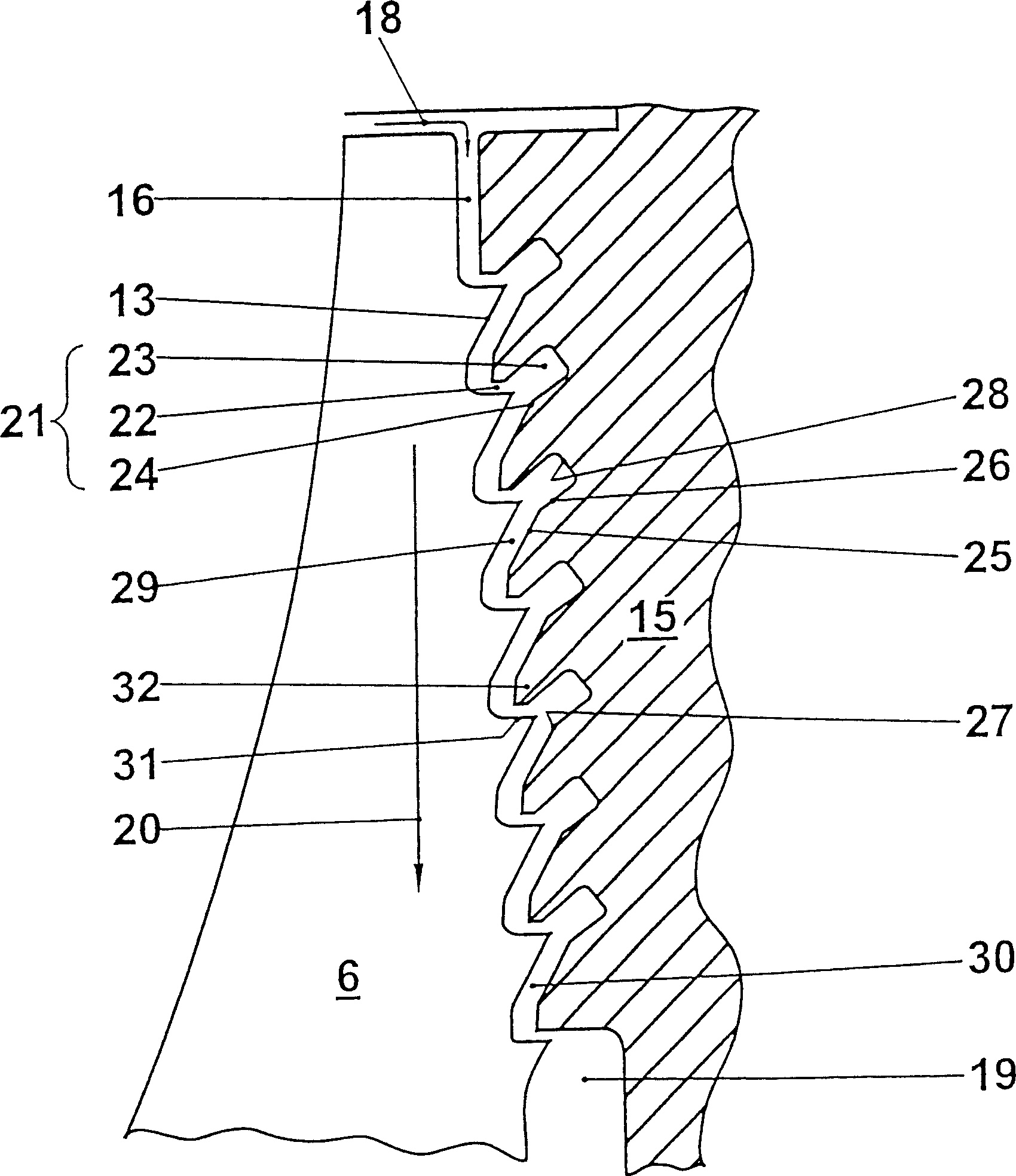

[0022] Only the main components to facilitate the understanding of the invention are shown in the figure, eg the output duct of the working fluid through the labyrinth seal, the turbine side and the support of the turbocharger are not shown. The flow direction of the working medium is indicated by arrows.

[0023] The prior art exhaust gas turbocharger, which is only partially shown in FIG. 1, consists of a centrifugal compressor 1 and an exhaust gas turbine, not shown in the figure, which are supported by a The shafts 3 are connected to each other. The centrifugal compressor 1 of the exhaust gas turbocharger has a machine shaft 4 in the shaft 3 and is equipped with a compressor housing 5 in which a rotor 6 formed as a compressor wheel is rotatable. Connected to axis 3. The compressor wheel 6 has a hub 8 on which a plurality of rotor blades 7 are mounted. A fluid channel 9 is formed between the hub 8 and the compressor housing 5 . Downstream of the rotor blades 7 , a radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com