Light-emitting diode (LED) backlight module and electronic equipment

A backlight module and LED light source technology, which is applied in the field of backlight lighting, can solve the problems of large thickness of the direct-type LED backlight module, light shadows formed by LED light sources, and low LED arrangement density, so as to avoid areas that cannot be illuminated and reduce The effect of mixing light distance and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

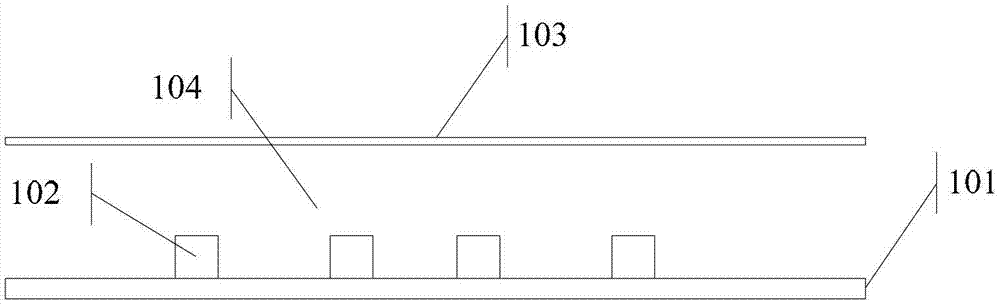

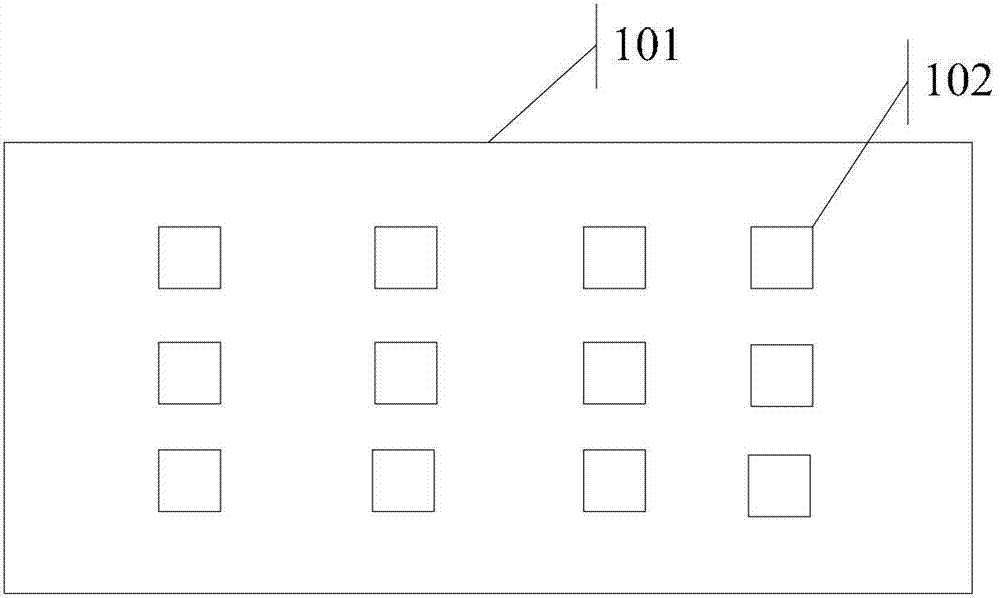

[0062] Embodiment 1 of the present application provides a direct-type LED backlight module, the direct-type LED backlight module includes:

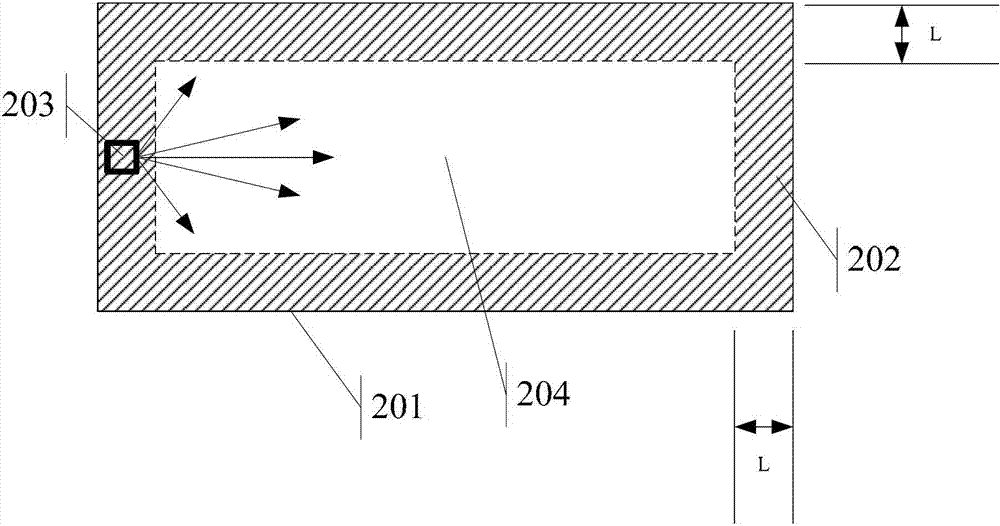

[0063] Please refer to Figure 2a and Figure 2b ,in, Figure 2a is the top view of the direct-lit LED backlight module, in Figure 2a The direct type LED backlight module includes a main reflector 201, which is divided into an edge area 202 and a central area 204, a first LED light source 203, and the first LED light source 203 is placed on the edge area of the main reflector 201 202, wherein the edge area 202 of the main reflector 201 is an area whose distance from the edge of the main reflector 201 is less than or equal to the first preset distance L, in Figure 2a The shaded area in is the edge area 202, and the size of the edge area 202 depends on the size of the first preset distance L.

[0064] In addition, the position processing of the first LED light source 203 can be Figure 2a In addition to the position in the present ...

Embodiment 2

[0093] Based on the same inventive concept, Embodiment 2 of this application provides a display device, please refer to Figure 10 , the TV specifically includes the following structure:

[0094] Chassis 111;

[0095] a processor 112, arranged in the casing 111;

[0096] The display unit 113 is arranged on the casing 111 and connected to the processor 112, wherein the display unit 113 includes:

[0097] LCD panel 114;

[0098] The direct type LED backlight module introduced in Embodiment 1 of the present application is arranged at the bottom of the liquid crystal panel 114 , and the liquid crystal panel 114 can be provided with uniform light through the direct type LED backlight module.

Embodiment 3

[0100] Based on the same inventive concept, the embodiment of the present application also provides an electronic device, and the electronic device specifically includes the following structure:

[0101] chassis;

[0102] a processor disposed within the housing;

[0103] A display unit is arranged on the casing and connected to the processor, wherein the display unit includes:

[0104] LCD panel;

[0105] The above-mentioned direct type LED backlight module is arranged at the bottom of the liquid crystal panel, and uniform light can be provided to the liquid crystal panel through the LED backlight module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com