Back plate of improved backlight unit

A backlight module and an improved technology, which is applied to the components of lighting devices, lighting devices, reflectors, etc., can solve the problems of complicated installation procedures of backlight modules, loss of optical energy, and increased labor load of workers, etc., to achieve installation The effect of increased troublesome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

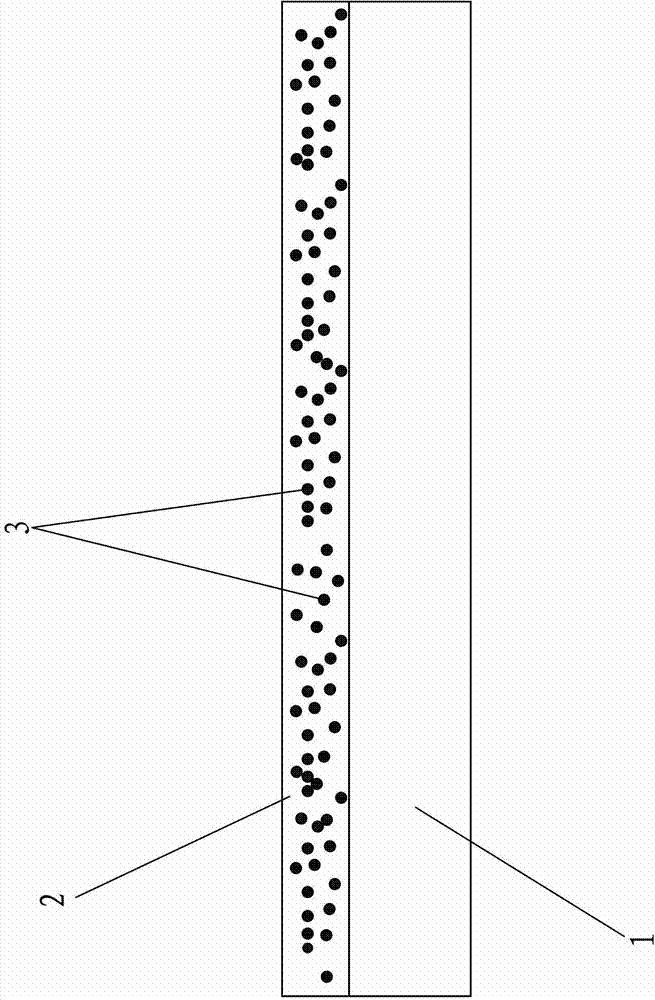

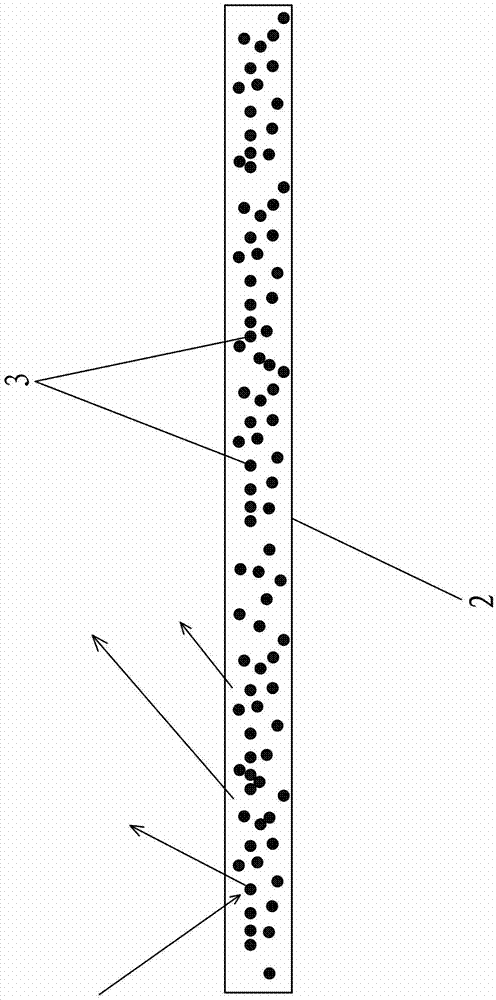

[0015] A backplane of an improved backlight module of the present invention, such as figure 1 , 2 As shown, it includes a bottom layer 1 and a high reflection layer 2 arranged on the bottom layer 1. The bottom layer 1 is an ABS plastic layer, and the high reflection layer 2 is a PC plastic layer doped with reflective particles 3. The bottom layer 1 and the high reflection layer The layer 2 is compounded together by high temperature heating, the thickness of the high reflection layer 2 is 100-350um, the reflective particles 3 are one of titanium oxide particles and barium sulfate particles, and the total weight of the reflective particles 2 accounts for the total weight of the PC plastic 10%-30% of.

[0016] The back plate of a kind of improved backlight module of the present invention, because a high reflective layer 2 is compounded on the original ABS plastic back plate, and high reflective layer 2 is the PC plastic layer that is mixed with reflective particles 3 in it, when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com