Metal-resistant super-high frequency radio frequency identification device (RFID) label

An RFID tag and ultra-high frequency technology, applied in the field of RFID electronic tags, can solve problems such as low reading efficiency, narrow bandwidth, and reduced communication distance, and achieve large receiving and radiating area, wide frequency bandwidth, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] structure

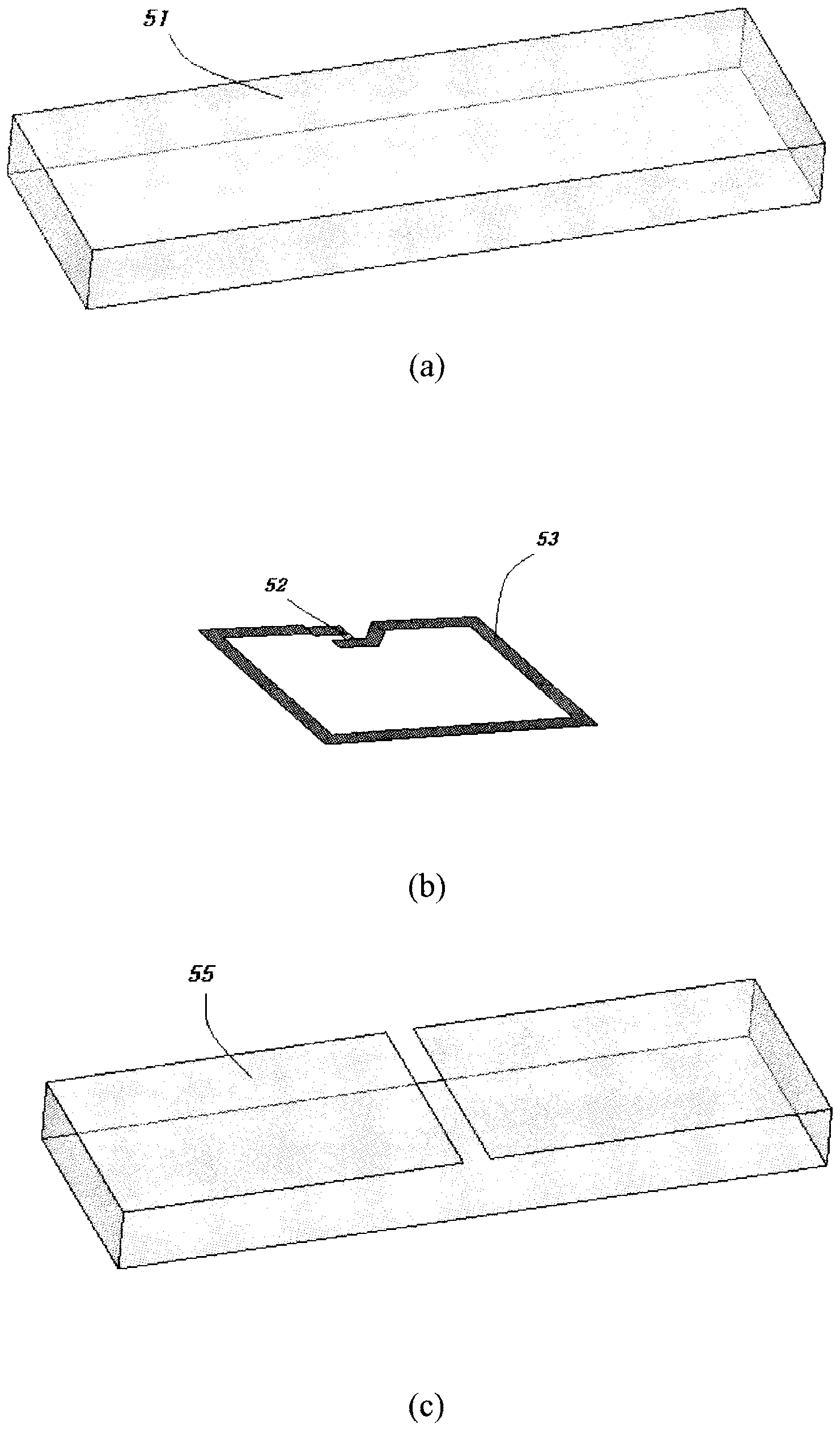

[0043] figure 1 It is a detailed three-dimensional exploded view of the RFID tag 50 of the present invention.

[0044] Such as figure 1 As shown in (a), the label dielectric member 51 is a dielectric plate with a size of 70x20x6mm.

[0045] Such as figure 1 As shown in (b), the integrated circuit chip 52 is mounted on the first loop antenna 53 to form a closed-loop near-field antenna; the first loop antenna is an etched antenna made of PET.

[0046] Such as figure 1 As shown in (c), the second loop antenna 55 is made of copper foil.

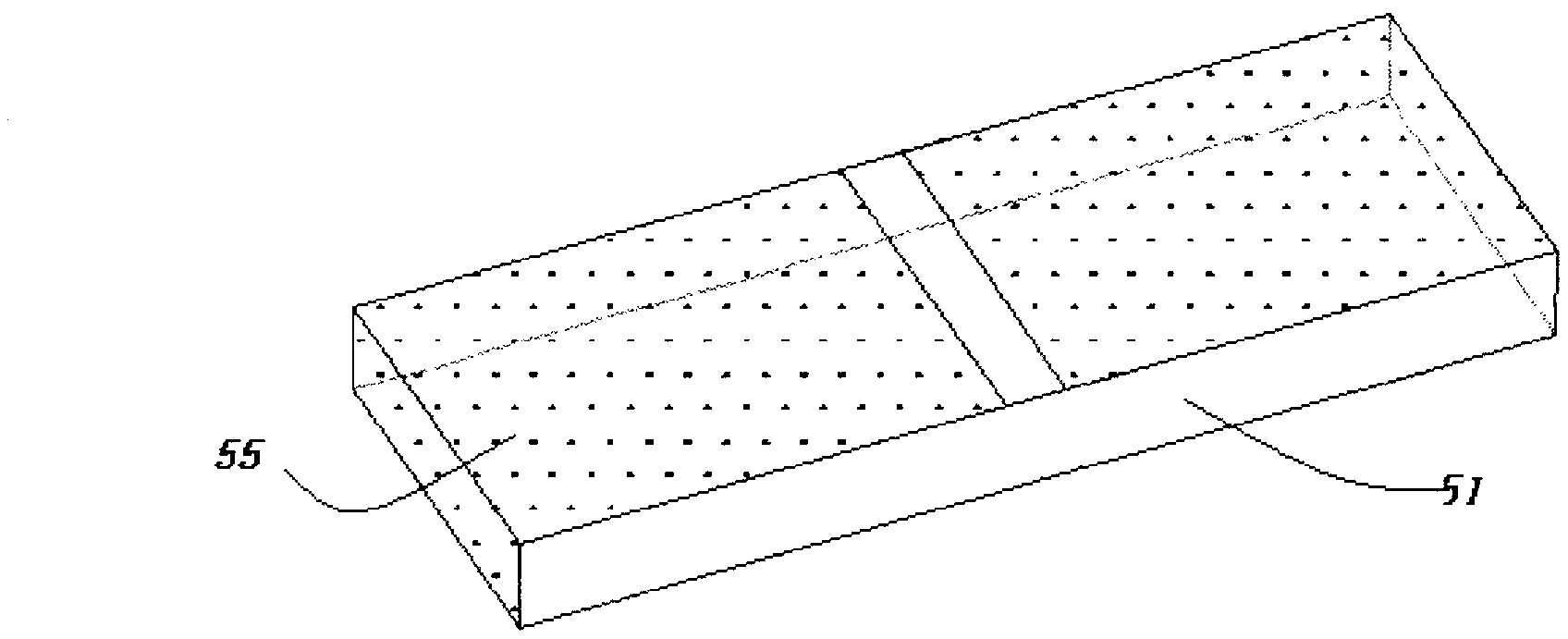

[0047] Such as figure 2 As shown, the second loop antenna 55 is attached to the label dielectric member 51 .

[0048] The label dielectric member 51 has, for example, a dielectric constant of 2.4, and can be formed using other inexpensive materials, such as a resin material with good formability.

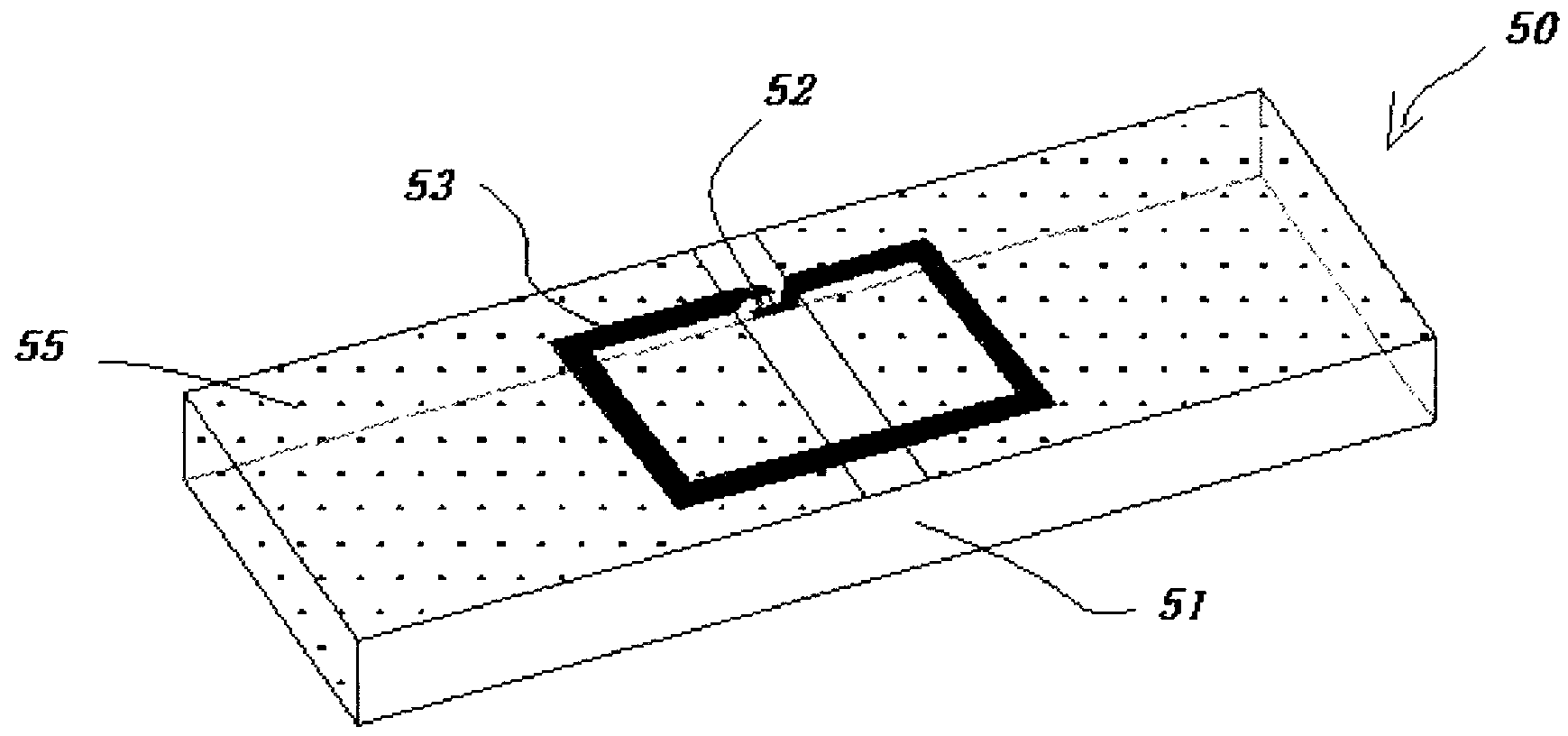

[0049] image 3 is a schematic diagram of an embodiment of the present invention after assembly, such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com