Small size dust collector motor cabin with noise reduction function

A small size, vacuum cleaner technology, applied in the direction of vacuum cleaners, electrical components, electromechanical devices, etc., to achieve the effect of reducing the sound pressure value, reducing the sound pressure value, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The detailed process of the present invention is described below with an embodiment, which is provided for the convenience of understanding, and is by no means limiting the present invention.

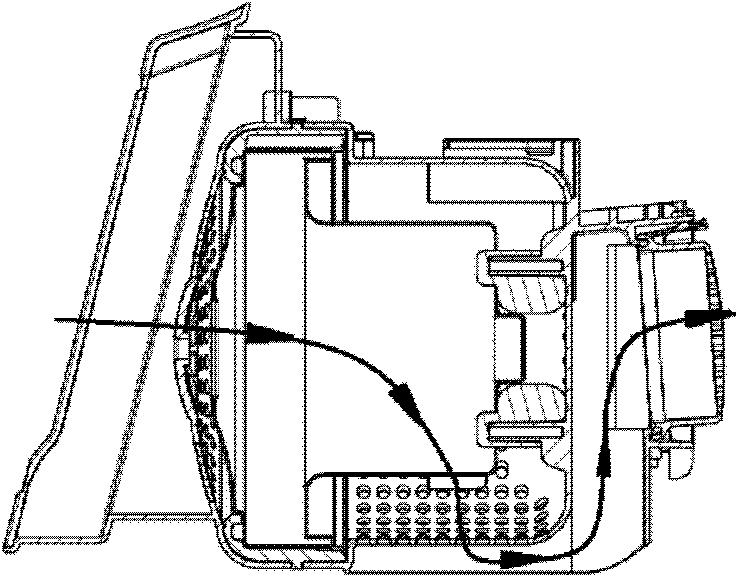

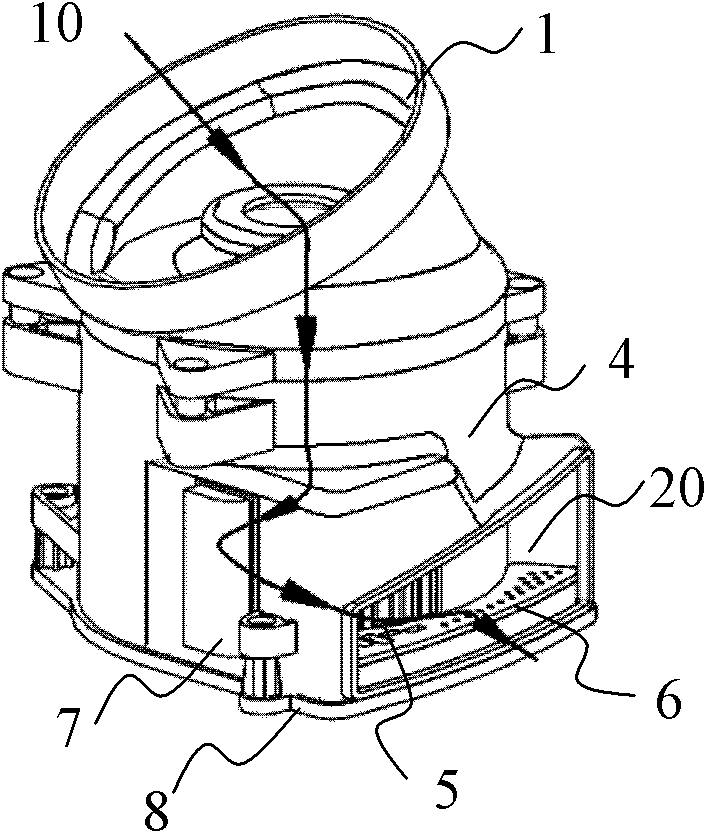

[0030] Such as figure 2 and image 3 As shown, the small-sized vacuum cleaner motor compartment with noise reduction function of the present invention mainly includes a motor cover 1, a motor assembly 2, a pre-filter 3, a motor case 4, an exhaust filter element 5 and a lower bottom plate 8, and the motor cover 1 A suction port 10 is provided at the top of the motor housing 4 , and an exhaust chamber 20 is formed between the motor housing 4 and the lower bottom plate 6 and outside the exhaust filter element 5 .

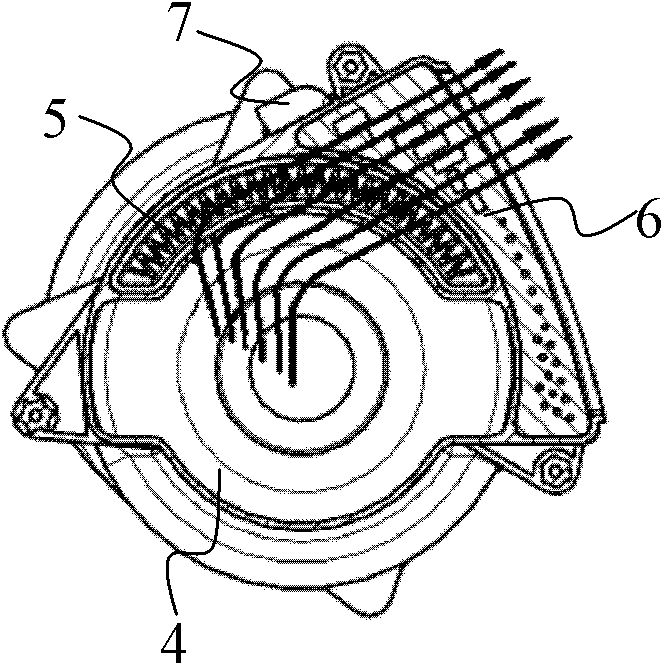

[0031] On the lower base plate 6, a wide-band muffler 6 is arranged at the position of the exhaust chamber 20, such as image 3 and Figure 4 The wide-band muffler 6 shown includes a main body 61, on which a plurality of L-shaped mufflers 62 arranged side by side are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com