Coal separation method for advanced dense medium cyclone technology

A heavy medium cyclone and process technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of large slime content, loss of clean coal, low ash content of tail slime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

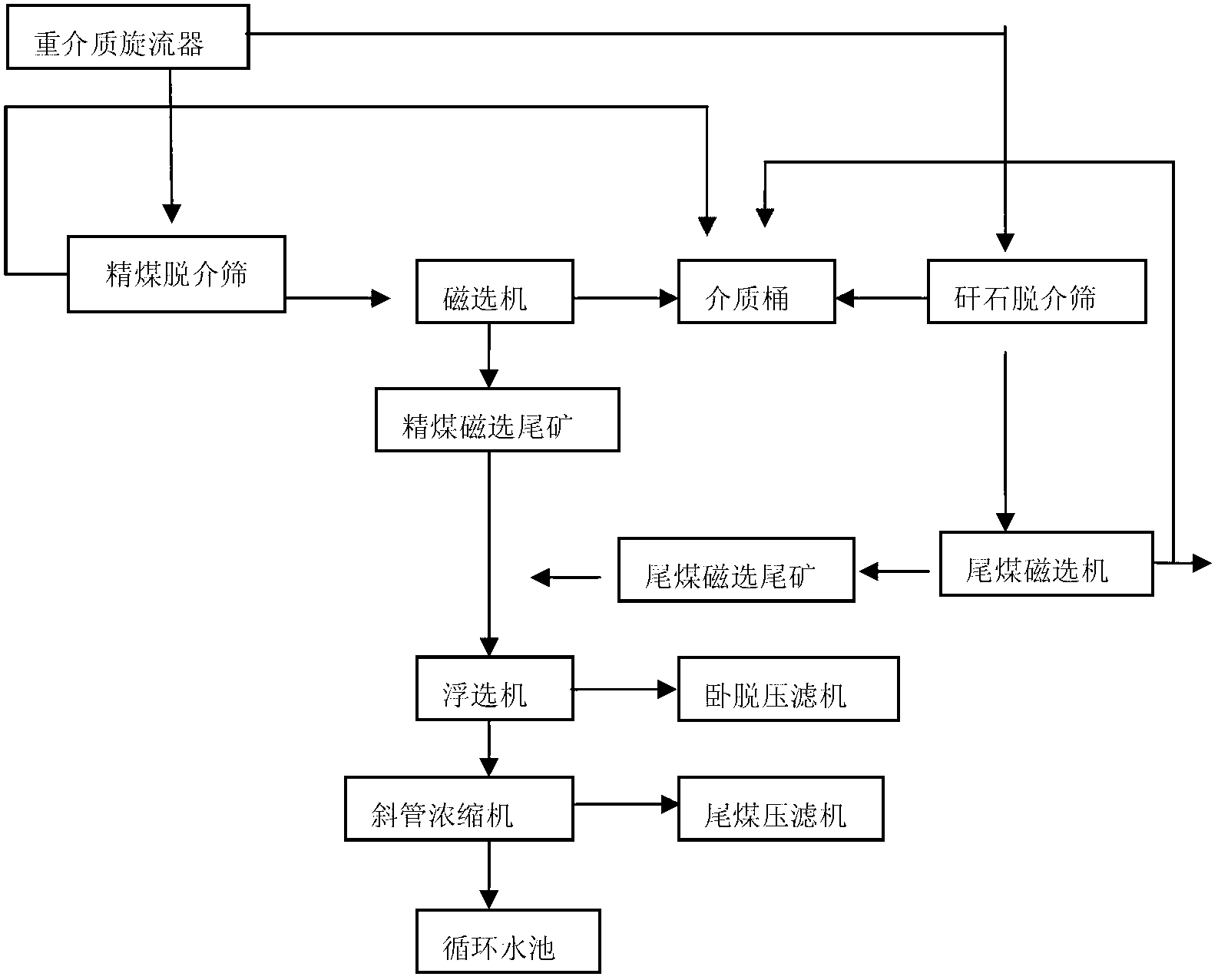

Method used

Image

Examples

Embodiment

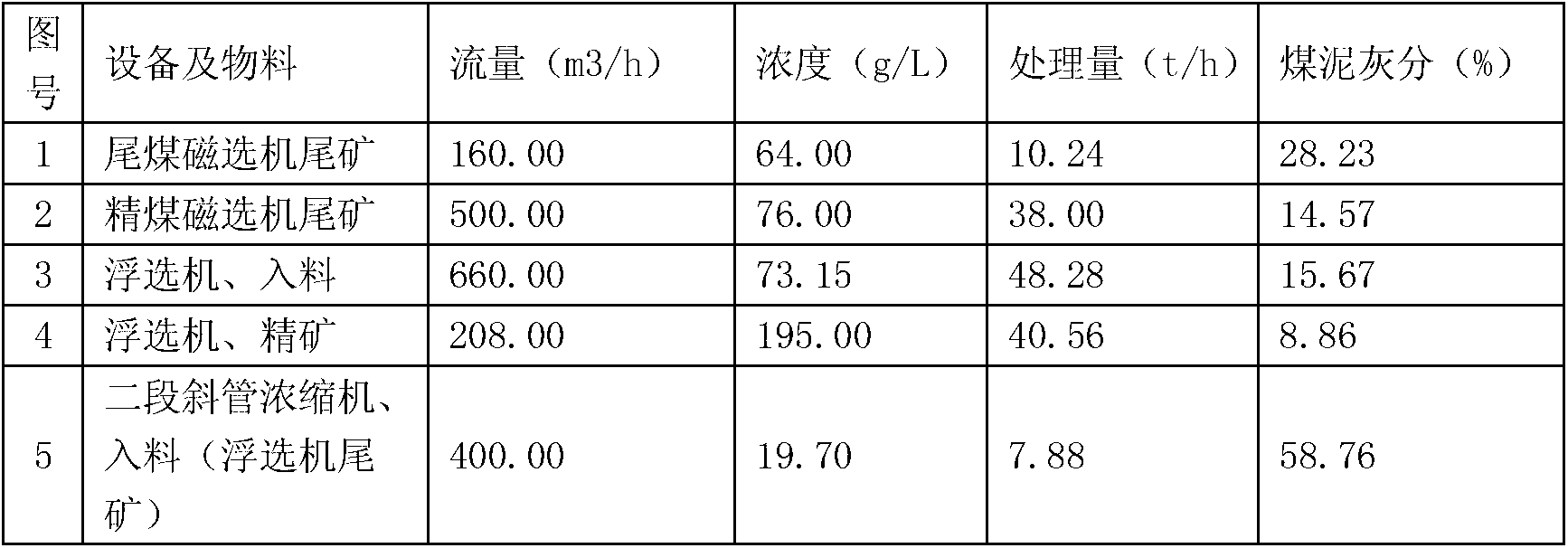

[0019] 1) Calculation of clean coal yield: the raw coal processing volume is 325 / h, after tailing coal magnetic separator tailings flotation, the ash content of tailing coal slime is calculated as 58.76%, and clean coal is calculated as 9%; clean coal yield X is assumed. , The flotation clean coal quantity index is 80%, and the flotation clean coal yield is 90%;

[0020] 28.32*100%=58.76*(100%-X)+8.86*X

[0021] X=61%

[0022] 10.24*61%=6.24 (t / h)

[0023] 6.24 / 330*100%=1.92%

[0024] 1.92%*80%=1.53%

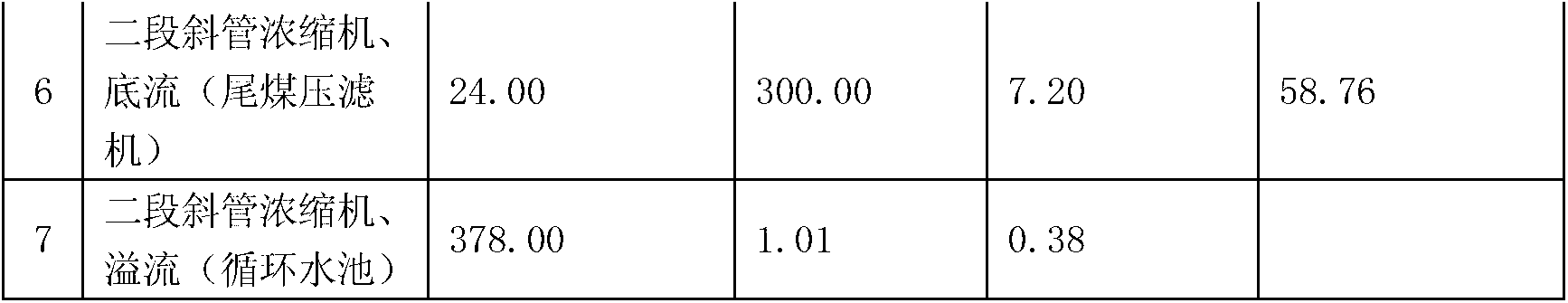

[0025] Calculation of flotation tailings coal volume: modified tailings coal slime volume: 10.24-6.24+38*(100%-90%)=7.8 (t / h), which is similar to the actual 7.2t / h; tailings coal filter press design The processing capacity is 10.0t / h, fully meeting the processing capacity of the modified coal slime.

[0026] 2) FJC-16-6 jet flotation machine is used for coal washing, and the design capacity is 640m 3 / h; According to the field data, the actual processing capacity of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com