A preventive method for reheating cracks in pipe seat fillet welds

A technology of reheat cracks and prevention methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inability to effectively prevent reheat cracks, waste, and product scrapping of thick-walled fillet welds, and solve the problem of tube sockets. Fillet weld reheat crack, reduce economic loss, ensure production cycle and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Application example when the outer diameter of the pipe seat is less than or equal to 76mm.

[0057] The inlet header of a high-temperature superheater in a certain project, the material of the header body is 12Cr1MoVG, and the specification is φ635×118mm. There are 384 pipe sockets with pipe joints, the material is 12Cr1MoVG, and the specification is φ57×8mm.

[0058] The welding process of the pipe seat fillet weld is as follows:

[0059] (1) Install and weld the fillet weld of the pipe seat according to the traditional process and requirements; the specific steps are as follows:

[0060] 1) Clean the welding area and the surrounding 20mm area to show a metallic luster;

[0061] 2) Preheat the welding area and the surrounding 400mm range to 200-250°C, and ensure that the interlayer temperature is 200-350°C during the welding process;

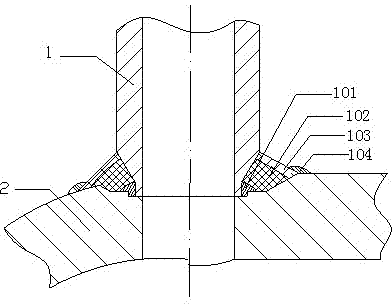

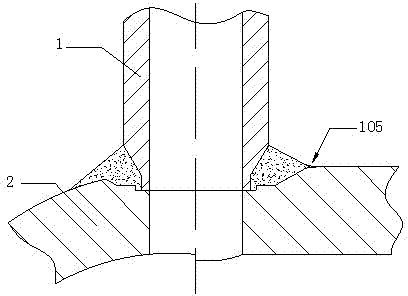

[0062] 3) if figure 1 As shown, the electrode arc welding uses the electrode with the brand name E5515-B2-V. The weldi...

Embodiment 2

[0071] Example 2 : An application example when the outer diameter of the pipe seat is greater than 76mm.

[0072] A certain engineering screen passes through an imported mixed header. The body of the header is made of 12Cr1MoVG with a specification of φ571.5×95mm. There are 10 pipe sockets with a material of 12Cr1MoVG and a specification of φ325×70mm arranged on the cylinder.

[0073] The welding process of the pipe seat fillet weld is as follows:

[0074] (1) Install and weld the fillet weld of the pipe seat according to the normal process and requirements, the specific steps are as follows:

[0075] 1) Clean the welding area and the surrounding 20mm area to show a metallic luster;

[0076] 2) Preheat the welding area and the surrounding 400mm range to 200-250°C, and ensure that the interlayer temperature is 200-350°C during the welding process;

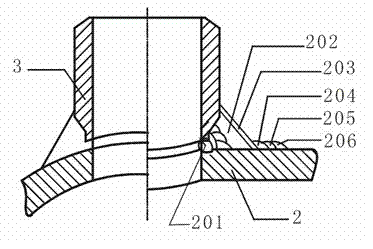

[0077] 3) if Figure 4 As shown, manual tungsten argon arc welding is used to make the base, and the welding material grade s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com