Numerical control grinder load spectrum data transfer sampling rate device and numerical control grinder load spectrum data transfer sampling rate method

A CNC grinding machine, variable sampling rate technology, applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem of affecting the normal operation of the tested machine, the sampling frequency is fixed, and the To reduce the load on the CPU, save storage space, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

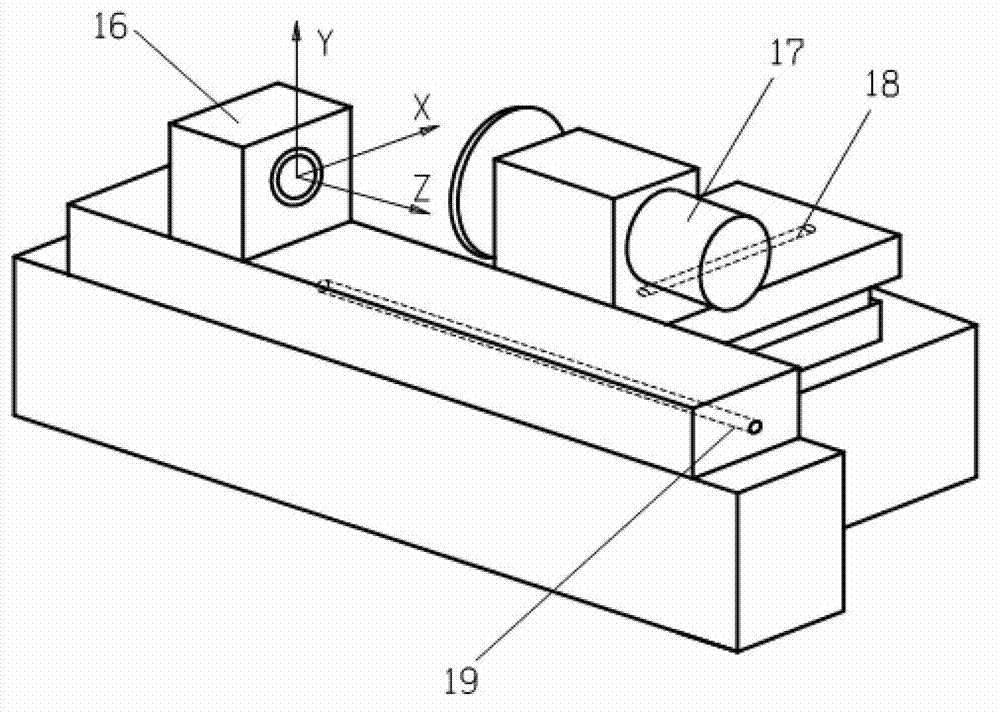

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

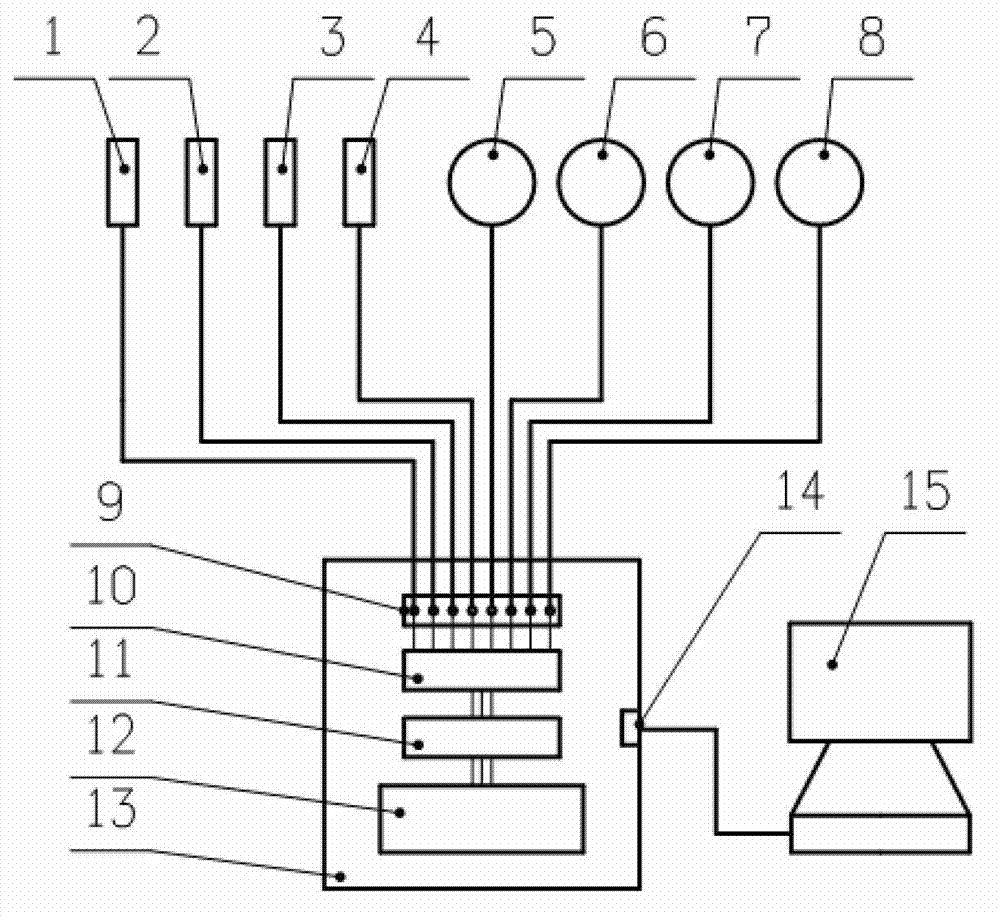

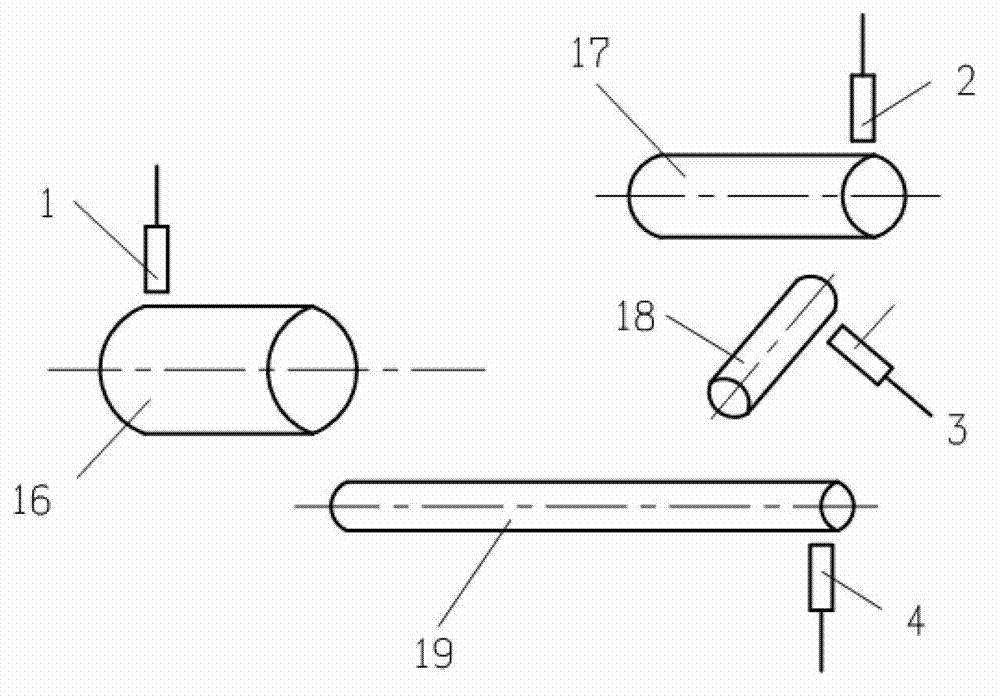

[0022] The establishment of the load spectrum of the CNC grinding machine usually requires data such as the speed of the CNC grinding machine at any time, the torque of the shaft, and the power of the motor, among which the speed and torque are necessary data. There are many ways to measure the rotational speed. In order not to change the mechanical structure of the CNC grinding machine, the present invention uses a non-contact rotational speed sensor, and the sensor is installed at the end of the rotating shaft and the lead screw, so as not to affect the operation and normal work of the CNC grinding machine. The standard analog signal output by the non-contact speed sensor is sent to the signal acquisition and processing board for processing. Such as figure 2 and image 3 As shown, the spindle speed sensor (1) is installed near the shaft end of the CNC gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com