Press table mechanism for sleeve winding machine

A winding machine and sleeve technology, which is applied in the direction of cardboard winding articles, coil manufacturing, etc., can solve the problems of insufficient smooth use, insufficient safety, inconvenient operation, etc., and achieve stable operation, reliable and safe parking, and left and right movement. Smooth up and down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

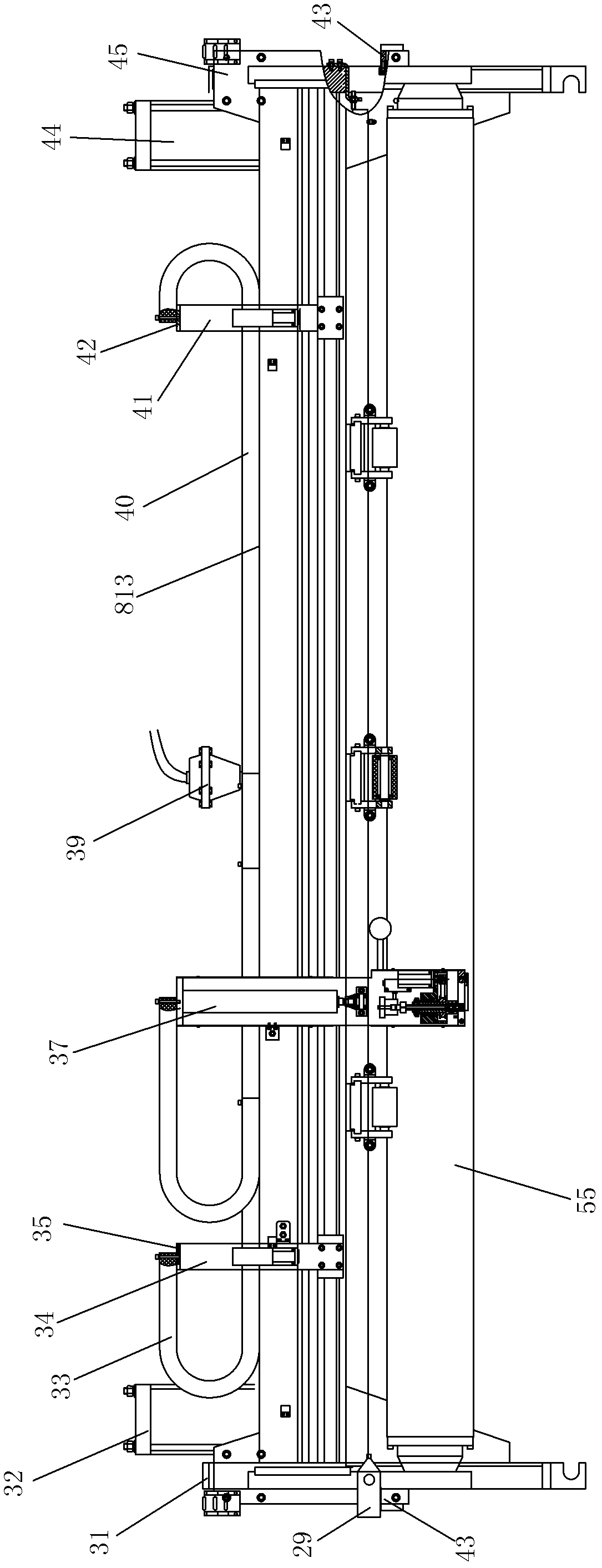

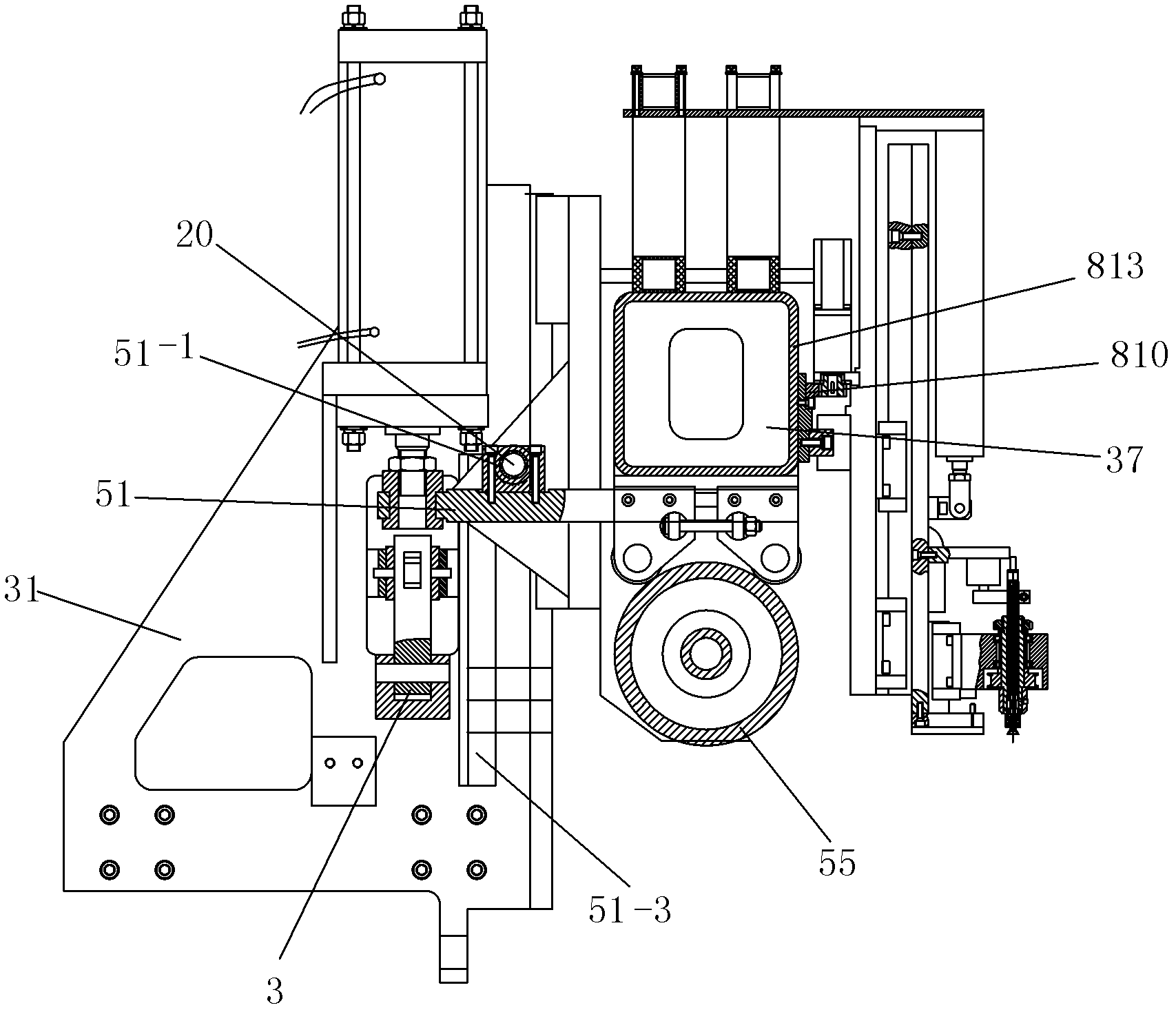

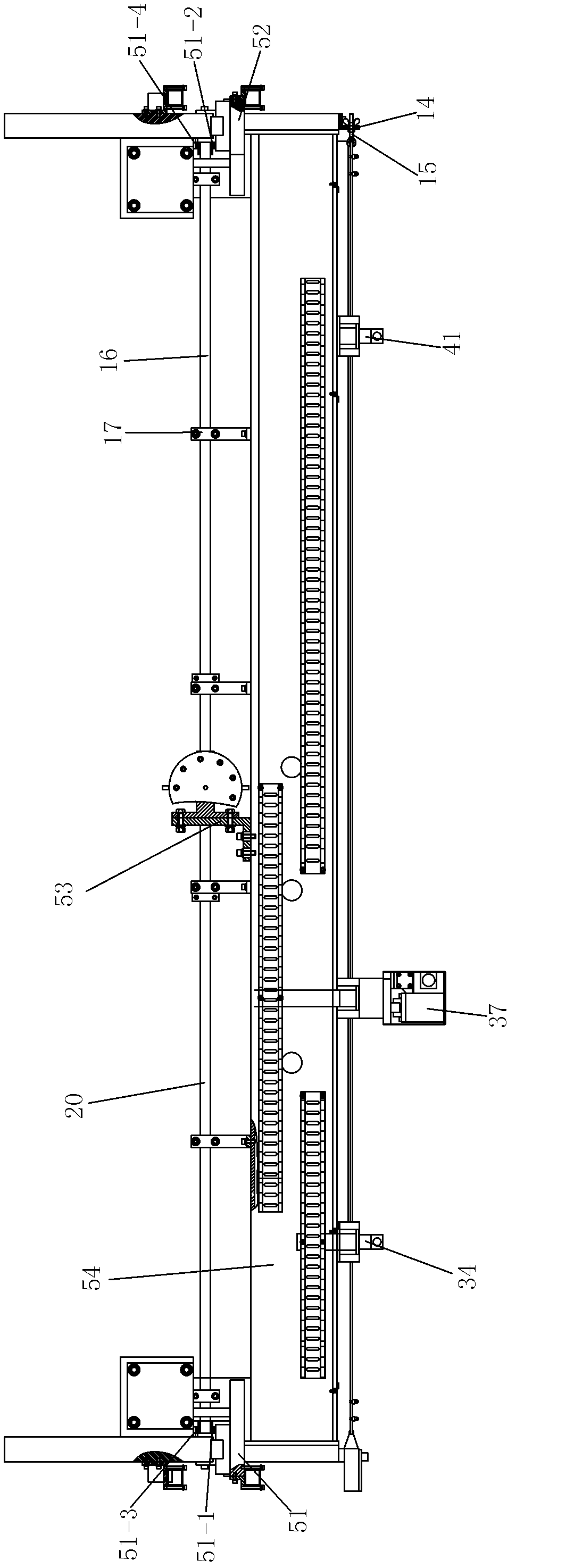

[0047] Such as Figure 1 to Figure 6As shown, the present invention includes a left support frame 31 and a right support frame 45 arranged in parallel to the left and right, and an electric heating roller 55, a rotating shaft, a laser marking device, and a punching device 37 arranged between the left support frame 31 and the right support frame 45 And braking device 39, described electric heating roller 55, rotating shaft and punching device 37 are all installed between left support frame 31 and right support frame 45, and described rotating shaft is installed on the punching device 37, and described left Cylinder one 32 is installed on the bracing frame 31, and cylinder two 44 is installed on the described right bracing frame 45, and the piston rod end of described cylinder one 32 is connected with punching device 37 by left lifting wallboard 51, and described cylinder two The piston rod end of 44 is connected with punching device 37 by right lifting wallboard 52 and cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com