Oxidation tank

An oxidation tank and tank body technology, applied in the field of oxidation tanks, can solve the problems of large running kinetic energy consumption, sedimentation, low opening rate, etc., and achieve the effects of high oxygen utilization rate, rapid oxidation reaction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

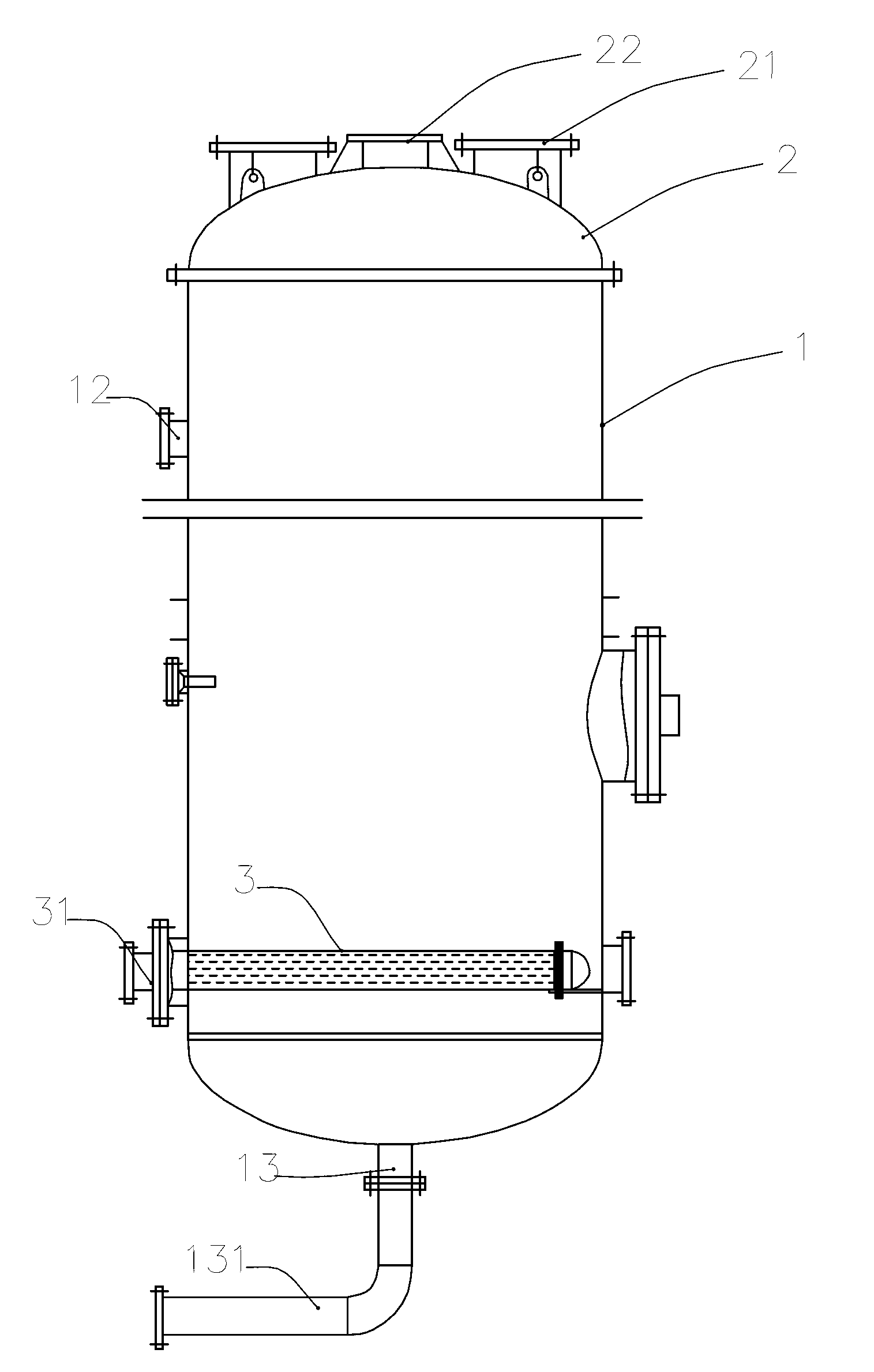

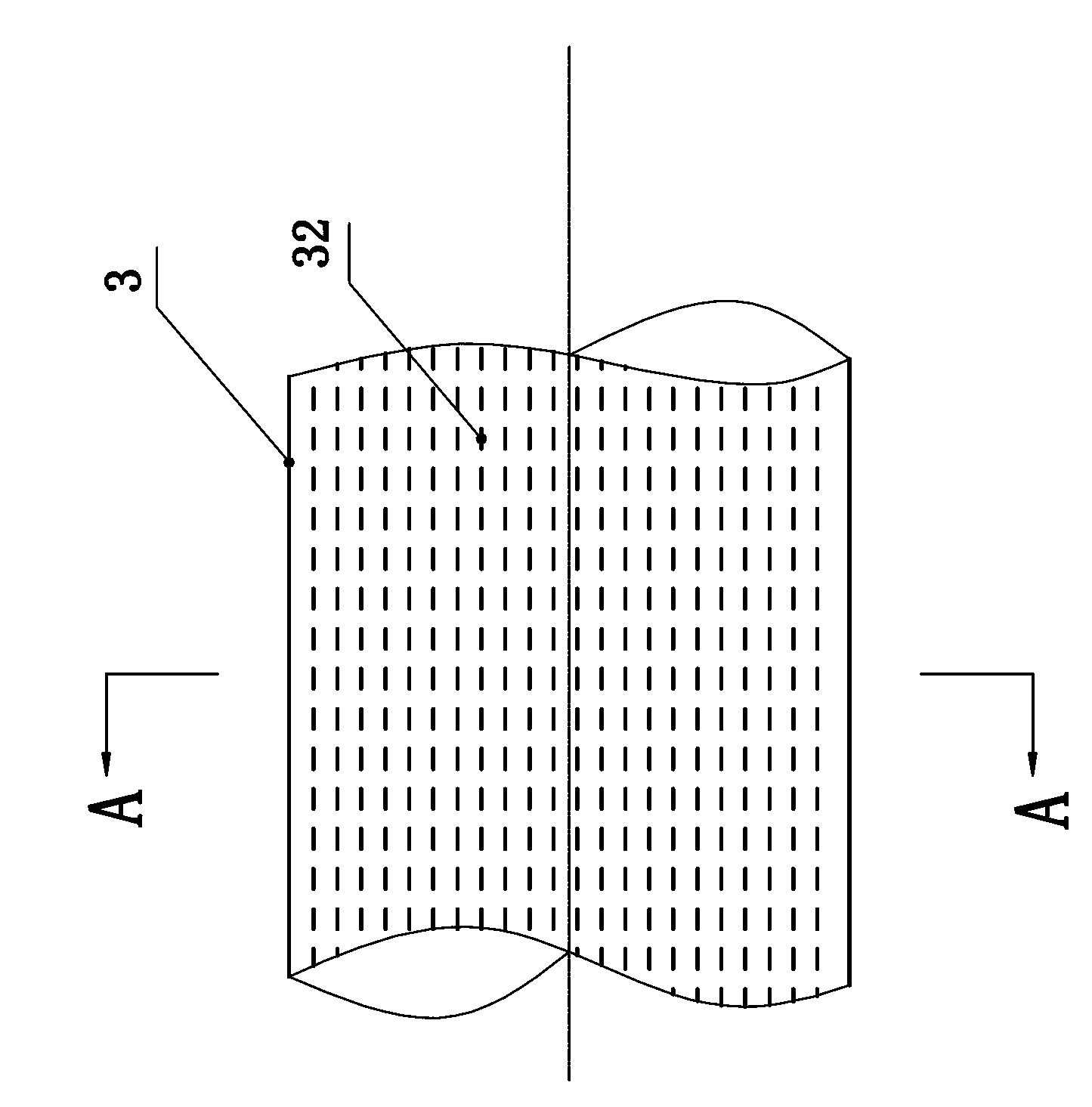

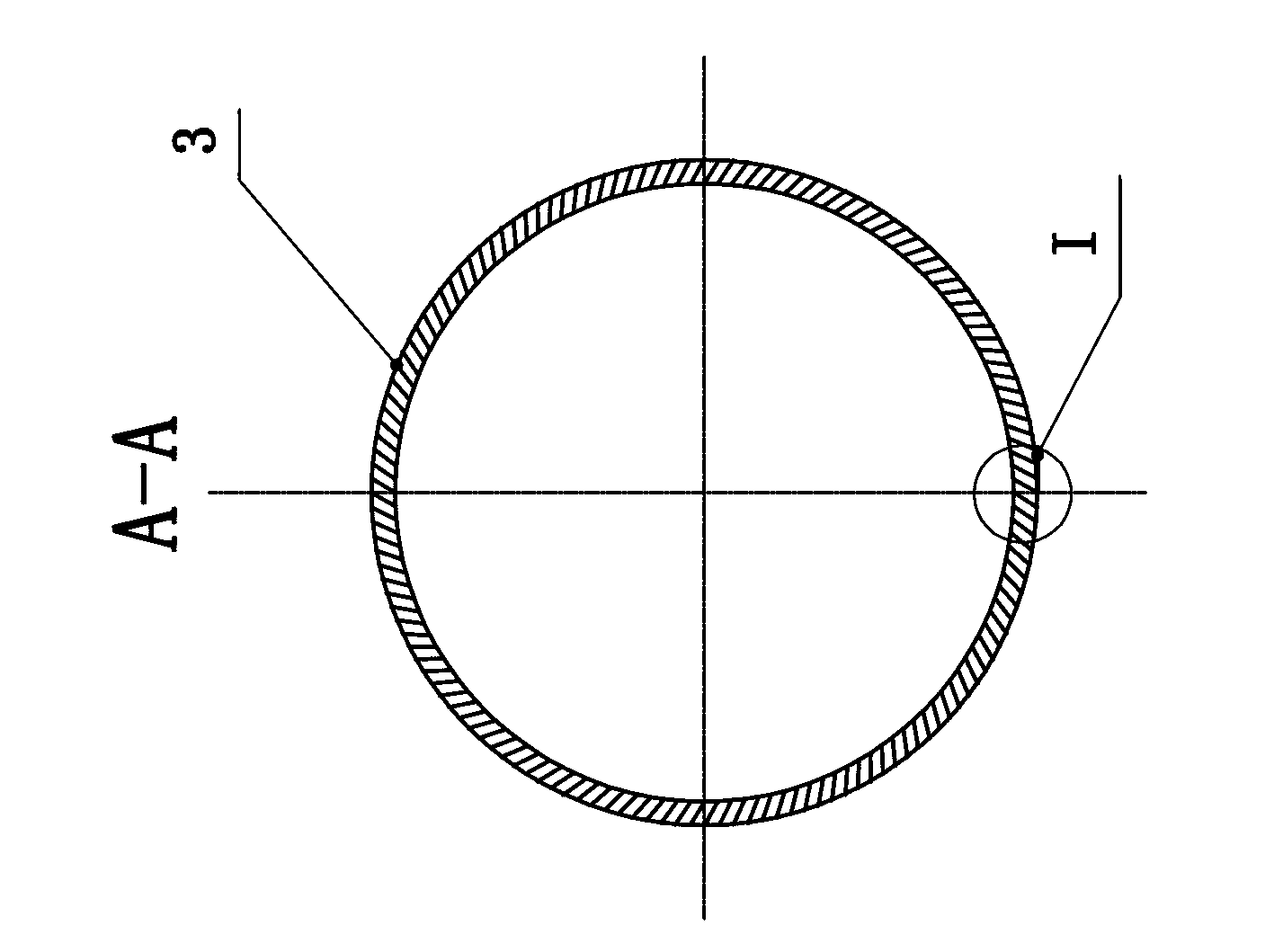

[0018] Such as Figure 1-5 The specific embodiment of the present invention shown includes a tank body 1 and an upper cover 2, the upper cover 2 is provided with an exhaust port 21, and the tank body is provided with a liquid inlet 12 and a liquid outlet 13. During the reaction, the lye enters the tank body from the liquid inlet 12. After the reaction is completed, the liquid in the tank is discharged from the liquid outlet 13. In this embodiment, the liquid outlet 13 is connected with a liquid outlet pipe 131. In addition, in this embodiment The tank body 1 described in the example is fixed with an oblique microporous aeration hose 3, the inner end of the oblique microporous aeration hose 3 is closed, and the outer end is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com