High temperature resisting powder paint and preparation method thereof

A technology of powder coating and high temperature resistance, applied in the field of chemical materials, can solve problems such as easy foaming and poor adhesion, achieve the effect of improving adhesion, improving surface adhesion, and eliminating easy foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

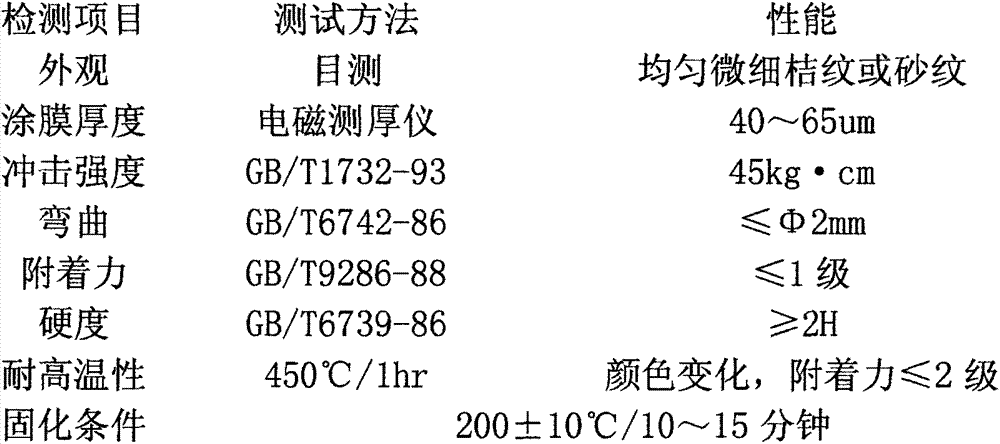

Image

Examples

Embodiment 1

[0021] The high-temperature-resistant powder coating described in the embodiment of the present invention has the mass fractions of various components: 40% of modified silicone resin, 3% of curing agent, 40% of high-temperature filler, 2% of auxiliary agent, and 0.5% of high-temperature pigment .

[0022] Its preparation method is:

[0023] Step 1: Put 55% by mass fraction of xylene and 45% by mass fraction of silicone resin into the reaction kettle, start stirring and slowly heat to 90° C. with steam, and keep the constant temperature until the silicone resin is completely dissolved;

[0024] Step 2: Pour epoxy-containing silane coupling agent and xylene equivalent to 3.5% of the mass fraction of silicone resin into the head tank at a ratio of 1:1 for later use;

[0025] Step 3: After the silicone resin is completely dissolved in the reaction kettle, raise the temperature to 120°C, open the discharge valve of the high level tank, and drop the mixture containing epoxy silane ...

Embodiment 2

[0029] The high temperature resistant powder coating described in the embodiment of the present invention has the mass fractions of various components: 55% modified silicone resin, 2% curing agent, 48% high temperature filler, 1% additive, and 3% high temperature pigment.

[0030] Its preparation method is:

[0031] Step 1: Put 55% by mass fraction of xylene and 45% by mass fraction of silicone resin into the reaction kettle, start stirring and slowly heat to 90° C. with steam, and keep the constant temperature until the silicone resin is completely dissolved;

[0032] Step 2: Pour epoxy-containing silane coupling agent and xylene equivalent to 3.5% of the mass fraction of silicone resin into the head tank at a ratio of 1:1 for later use;

[0033] Step 3: After the silicone resin is completely dissolved in the reaction kettle, raise the temperature to 120°C, open the discharge valve of the high level tank, and drop the mixture containing epoxy silane coupling agent and xylene ...

Embodiment 3

[0037] The high-temperature-resistant powder coating described in the embodiment of the present invention has the mass fractions of various components: 50% modified silicone resin, 2.5% curing agent, 44% high-temperature filler, 1.5% additive, and 1.5% high-temperature pigment.

[0038] Its preparation method is:

[0039] Step 1: Put 55% by mass fraction of xylene and 45% by mass fraction of silicone resin into the reaction kettle, start stirring and slowly heat to 90° C. with steam, and keep the constant temperature until the silicone resin is completely dissolved;

[0040] Step 2: Pour epoxy-containing silane coupling agent and xylene equivalent to 3.5% of the mass fraction of silicone resin into the head tank at a ratio of 1:1 for later use;

[0041] Step 3: After the silicone resin is completely dissolved in the reaction kettle, raise the temperature to 120°C, open the discharge valve of the high level tank, and drop the mixture containing epoxy silane coupling agent and x...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com