Piezoresistive high-frequency dynamic soil stress sensor and fabricating method thereof

A stress sensor and high-frequency dynamic technology, which is applied in the field of sensors for soil stress measurement, can solve problems such as poor precision, low frequency response, and large sensor diameter, and achieve the effects of small size, high range, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

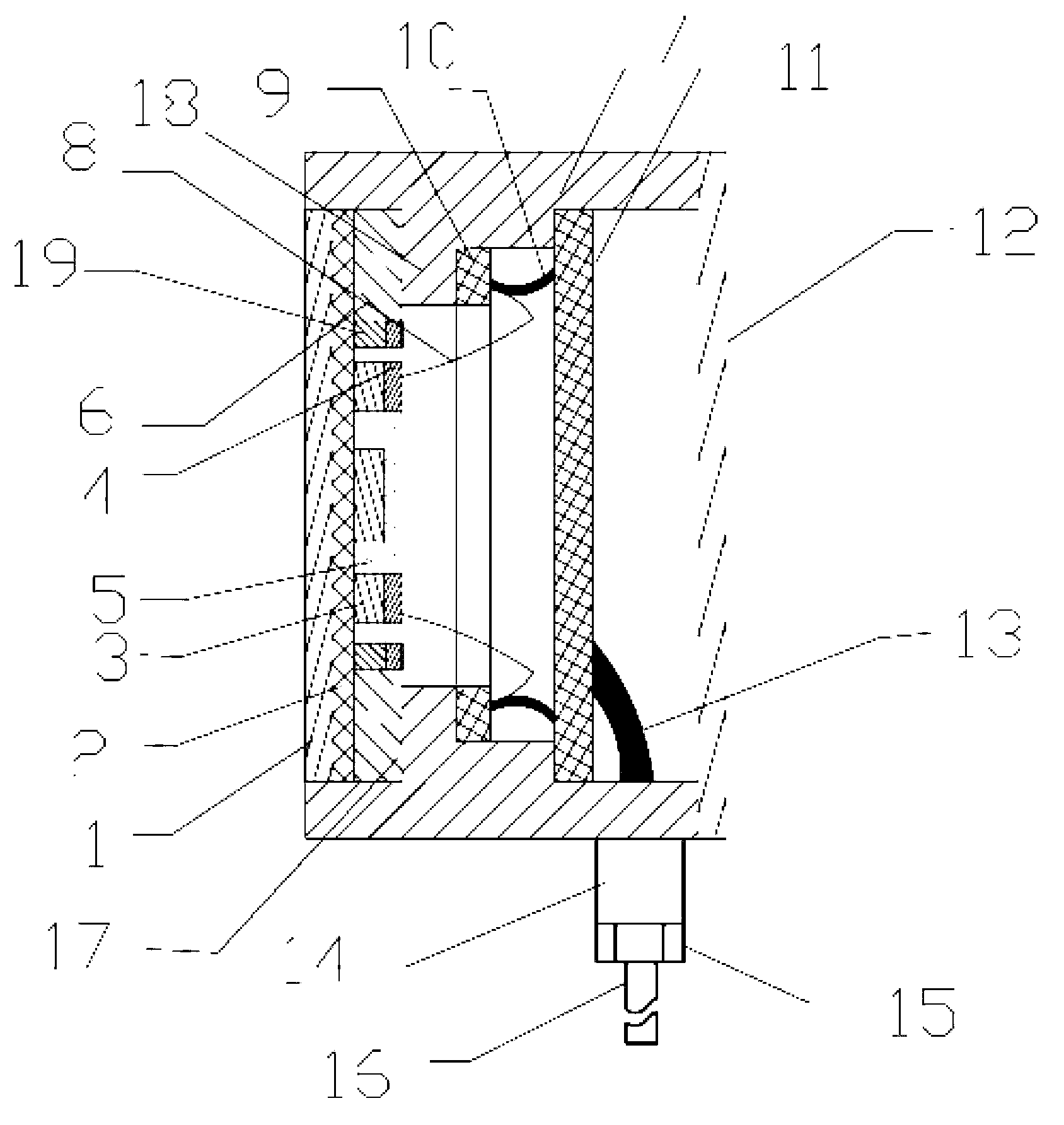

[0023] The following is attached figure 1 For further description:

[0024] A high-frequency dynamic force sensor for measuring soil stress in the surrounding environment of underground hazardous waste is mainly composed of a sensor housing 7, a stress-sensitive component and a signal conditioning amplifier circuit 11. The sensor housing is made of high-quality Hitachi alloy, and the stress Sensitive components include the structure of the stress-sensitive components of the soil stress high-frequency dynamic sensor in the present invention. The structure is made of substrate 1—insulation isolation layer 2—boron-doped P-type microcrystalline silicon strain resistance 3—insulation protection layer 5; The component is electrostatically sealed to the fixed support step 18 at the front end of the sensor housing 7 through borosilicate glass 6. The stainless steel diaphragm 1 of the stress-sensitive component and the sensor housing 7 are fixed by laser welding. The gold electrode 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com