Reinforcement bar and method for manufacturing same

A technology of reinforcing strips and fibers, used in building reinforcements, building construction, transportation and packaging, etc., can solve the problems of negative effects of concrete dehydration and curing process, difficult mixing of water absorption tendency, clogging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

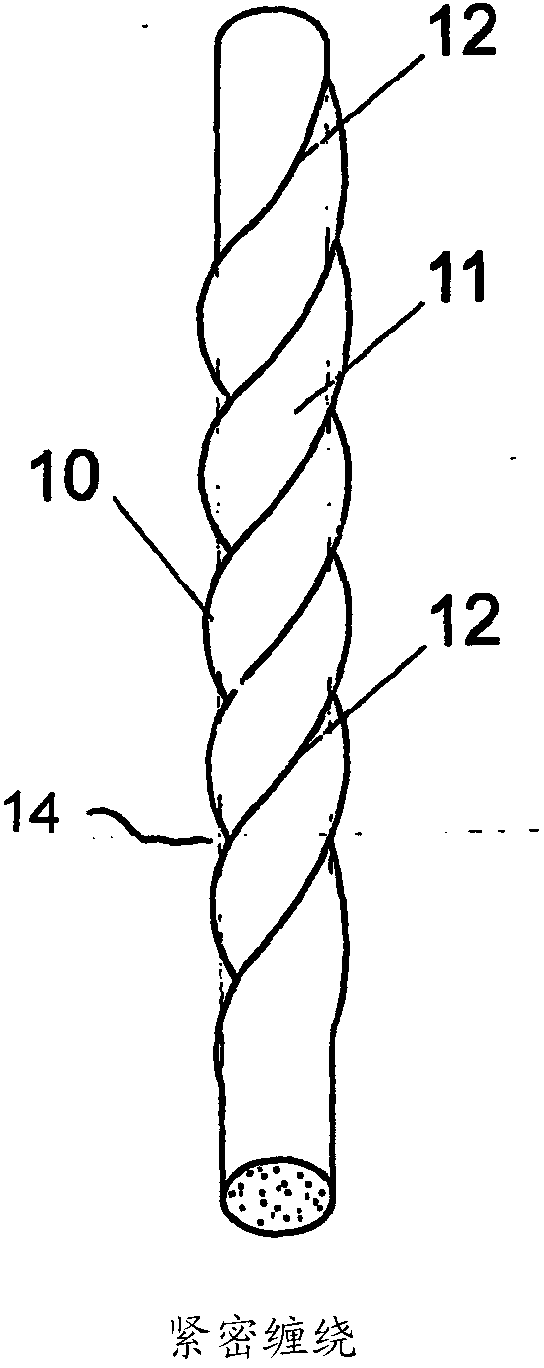

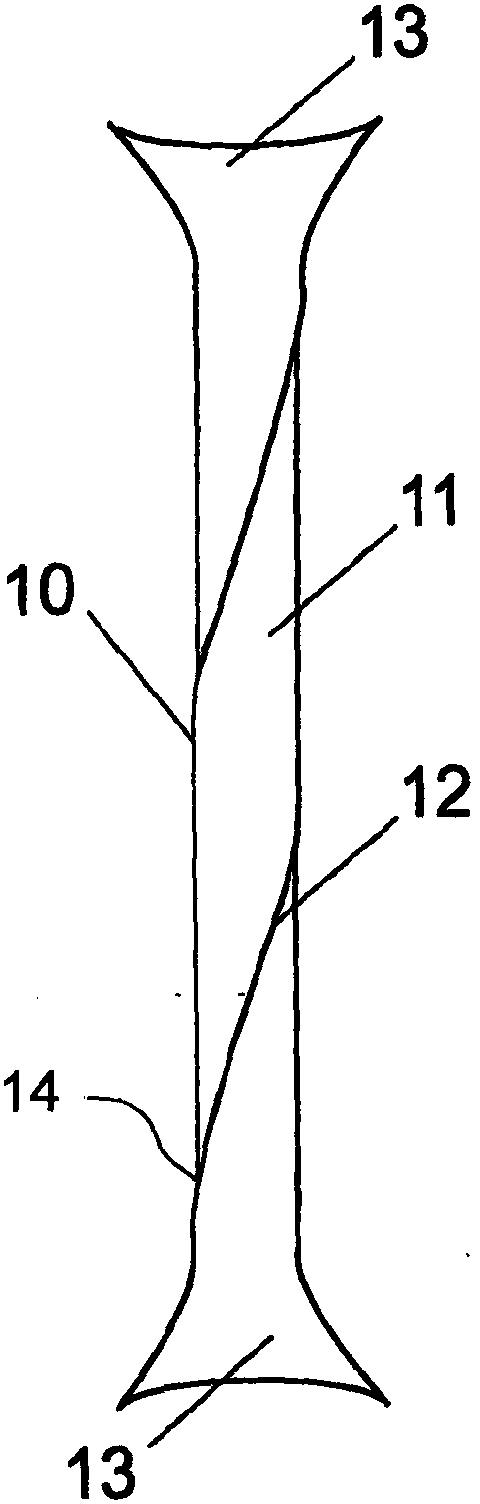

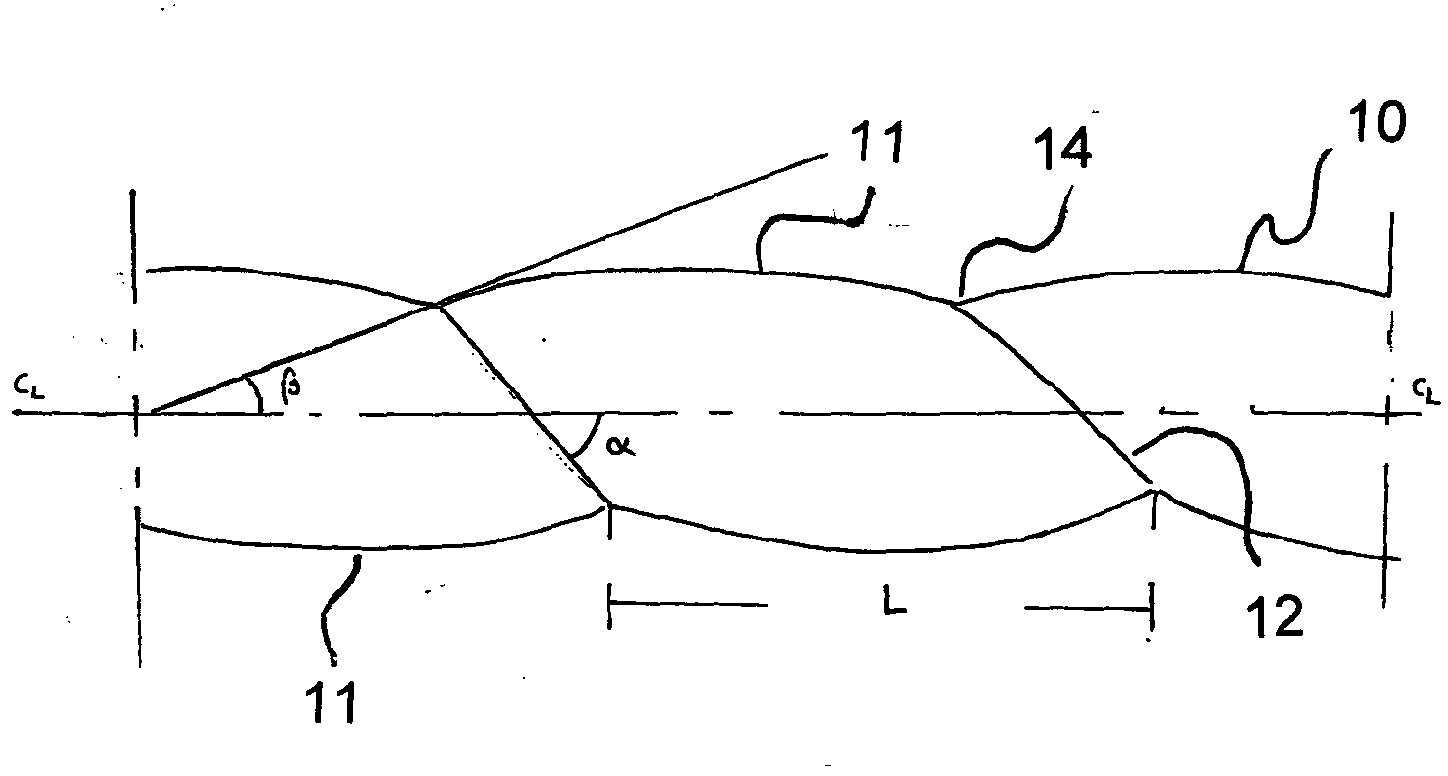

[0105] figure 1 Schematically shows a MiniBar according to the present invention TM 10 view of the first embodiment. MiniBar TM 10 comprises a plurality of parallel fibers 11 of basalt, glass fibers or carbon embedded in a cured matrix of conventional type resistant to alkaline corrosion. Such a matrix may be, for example, thermoplastic, vinyl ester (VE) or epoxy. An elastic or non-elastic strand 12 is continuously wound around the elongated embedded fibers, and tension is applied to the strand 12 to partially deform the circumferential surface of the strip 10, creating an elongated helically arranged indentation 14. This winding operation is preferably carried out simultaneously with or after the embedding of the elongated fibers 11 in the matrix, but before the final curing step, so as to ensure the desired deformation of the circumferential surface of the strip 10 . Further, MiniBar TM 10 The elongated rope or strip can be made in a continuous process, whereupon the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com