Self-cleaning plastic film with lotus leaf structure, surface microstructure and preparation method thereof

A micro-structure, self-cleaning technology, applied in coating and other directions, can solve the problems of unable to achieve self-cleaning function, affecting the self-cleaning function of finished products, complex processing procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

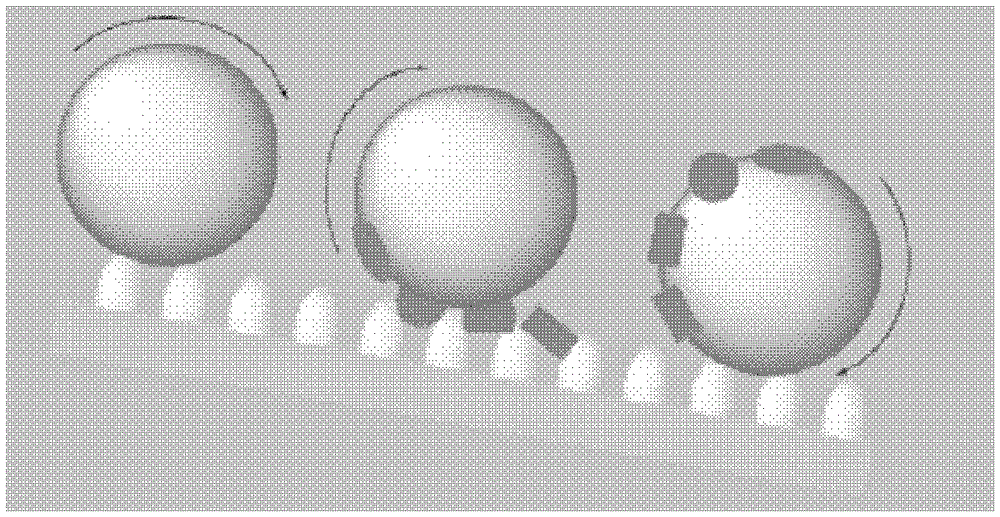

[0029] In nature, such as figure 1 As shown, the surface of lotus leaf has a unique self-cleaning function, which is determined by its surface microstructure and chemical substances containing low surface energy. We use scanning electron microscopy to observe the surface of lotus leaf. Such as figure 2 As shown, it can be found that the surface of the lotus leaf has microstructures arranged in a certain order. image 3 is a schematic diagram of the contact angle between the surface microstructure of the lotus leaf and the water droplet, such as Figure 4 It is the effect diagram of the application of microstructures with hydrophobic or self-cleaning functions on different materials, from left to right are the effects obtained on glass materials, ceramic materials and metal materials.

[0030] Water droplets have different contact angles on microstructures of different materials, such as Figure 5 As shown, the schematic diagram of the hydrophilic effect of water droplets u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com