Method of reverse water gas shift reaction for reverse water gas shift catalyst

A technology for shifting catalyst and reverse water gas, applied in the directions of carbon monoxide, reagents, educts, etc., to achieve good catalytic activity, low cost, and good activation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

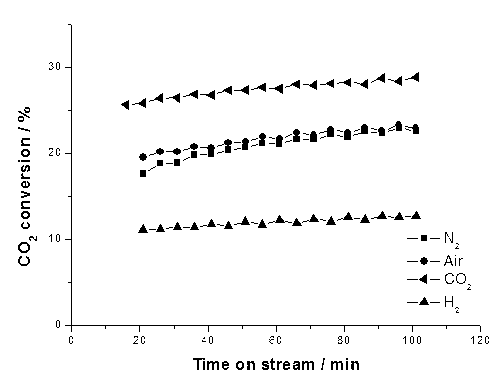

Image

Examples

Embodiment 1

[0030] (1) Activation of the catalyst

[0031] Use 60-100 mesh nickel-cerium catalyst with a mass percentage of 0.25% nickel as the reverse water gas shift catalyst, and use high-purity carbon dioxide gas with a purity of more than 99.99% to activate the nickel-cerium catalyst at 600 ° C for 2 hours, calculated as 1 mg of nickel-cerium catalyst , high-purity carbon dioxide gas ventilation rate at 2.5ml / min.

[0032] (2) Reverse water gas shift reaction

[0033] Mix the activated nickel-cerium catalyst with 60-100 mesh quartz sand evenly in a weight ratio of 1:2.5, and pass the raw material gas of the reverse water gas. Based on 1 mg of nickel-cerium catalyst, the ventilation rate of the raw material gas of the reverse water gas is 5ml / min. The composition of water gas raw material gas is 50vol.%CO 2 , 50vol.%H 2 ; Catalyzed reaction at 600 ° C to obtain water gas.

Embodiment 2

[0035] (1) Activation of the catalyst

[0036]Use 60-100 mesh nickel-cerium catalyst with a mass percentage of 0.5% nickel as the reverse water gas shift catalyst, and use high-purity carbon dioxide gas with a purity of more than 99.99% to activate the nickel-cerium catalyst at 800 ° C for 1 hour, calculated as 1 mg of nickel-cerium catalyst , high-purity carbon dioxide gas ventilation rate at 5ml / min.

[0037] (2) Reverse water gas shift reaction

[0038] Mix the nickel-cerium catalyst after the activation treatment with 60-100 mesh quartz sand according to the weight ratio of 1: 3, and feed the feed gas of reverse water gas. Based on 1 mg of nickel-cerium catalyst, the ventilation rate of feed gas for reverse water gas is 8ml / min. The composition of water gas raw material gas is 50vol.%CO 2 , 50vol.%H 2 ; Catalyzed reaction at 800 ° C to obtain water gas.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com