High density circulating fluidized bed device of four-point air-inflated structure used B category particle

A circulating fluidized bed and air-filled structure technology, applied in the field of clean energy, can solve problems such as reducing fuel conversion rate and utilization rate, hidden dangers of device safety operation, and affecting gas-solid two-phase heat and mass transfer efficiency, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

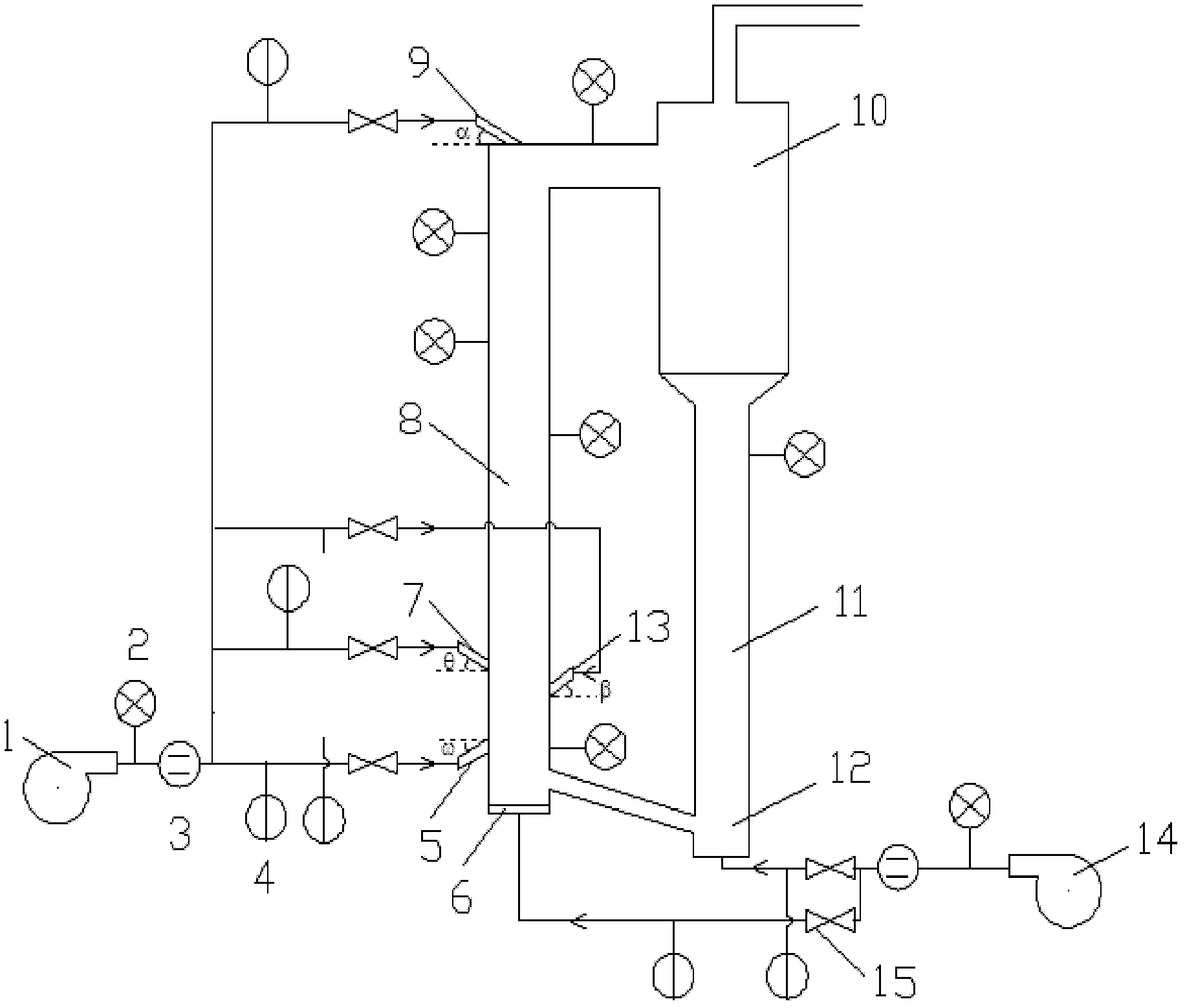

[0031] See figure 1 , is a high-density circulating fluidized bed device using B-type particles in a four-point inflatable structure of the present invention, which is composed of an air supply system, a main bed system, a separation system, a material return system and a test system. Including: two air compressors 1, 14, multiple manual valves 15, multiple pressure sensors 2, multiple temperature sensors 3, multiple mass flow meters 4, air distribution plate 6, riser pipe 8, cyclone separator 10, lower Feed pipe 11, J valve return feeder 12. Among them, three aeration points are asymmetrically distributed at the bottom of the riser 8 of the high-density circulating fluidized bed using B-type particles, and one aeration point is arranged at the top of the riser 8 above the strongly restricted outlet. Wherein the high-density circulating fluidized bed according to Grace etc. (references are: J.R.Grace, A.S.Issangya, D.Bai. 2116.) to define the standard, that is: the solid flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com