Screw air compressor oil composition

A technology of air compressor oil and composition, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve the problems of compressor operation failure, easy oxidation of lubricating oil, increase of sludge, etc. Generate trending effects

Inactive Publication Date: 2013-07-03

PETROCHINA CO LTD

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The screw air compressor that dominates the compressor, the lubricating oil used is in high temperature and high pressure environment in contact with the air for a long time, the lubricating oil is easily oxidized, causing the viscosity, acid value and sludge of the oil to increase, resulting in the operation of the compressor Fault

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

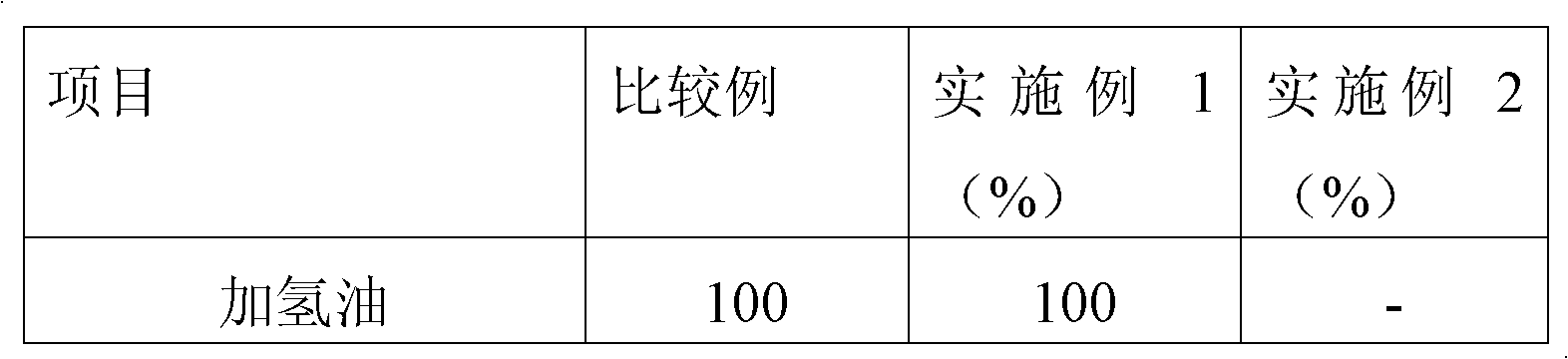

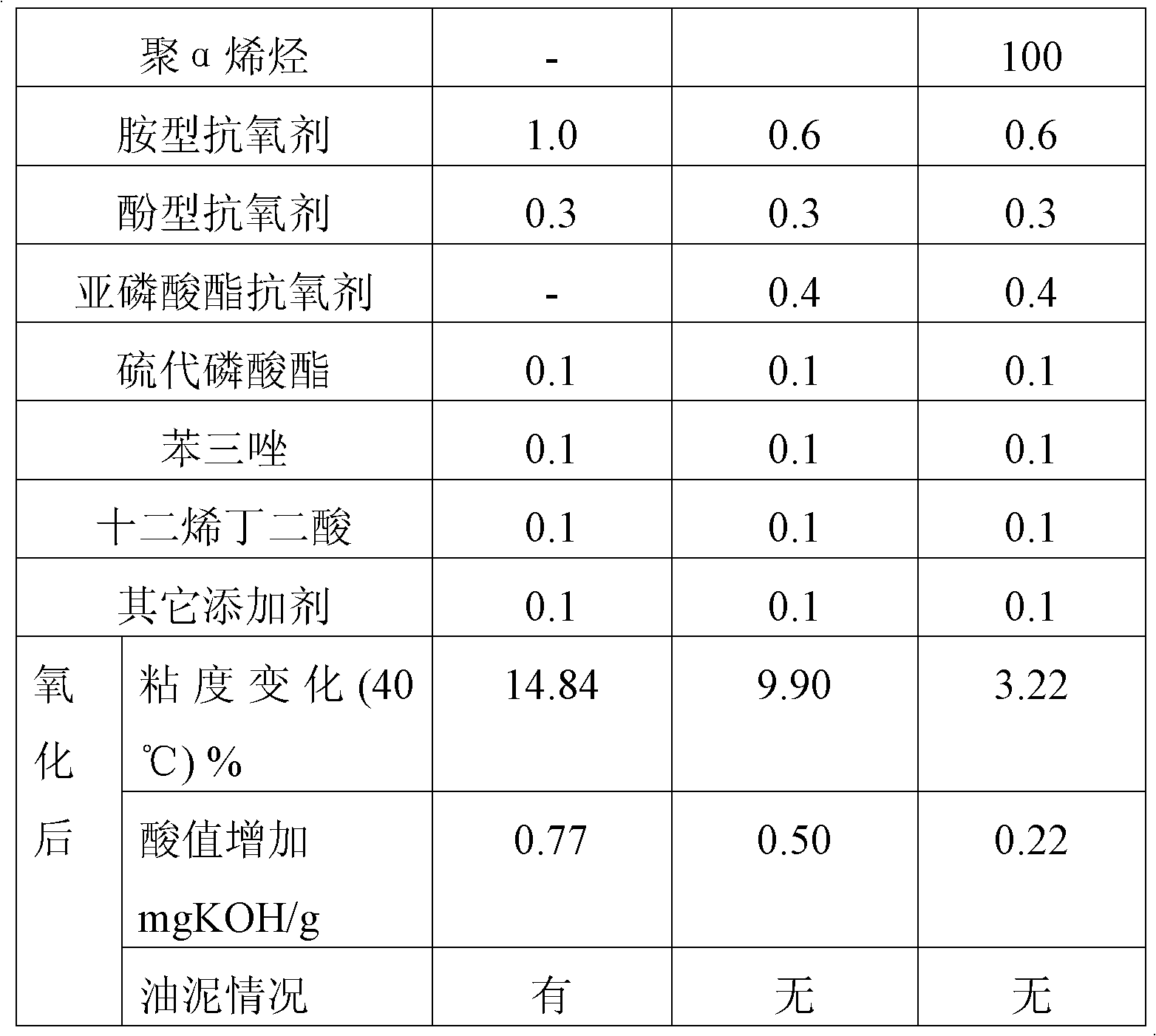

[0021] The preparation method of this example: put the base oil into the blending kettle, add antioxidants, extreme pressure and anti-wear agents, anti-rust and anti-corrosion agents and other additives in the proportions listed in the table, heat to 60-80 °C, and keep the temperature constant Stir for 1-2 hours, cool down to 50°C, filter and package to obtain the product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

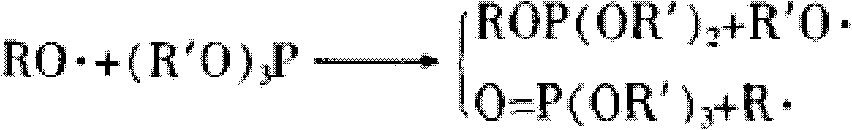

The invention relates to a screw type air compressor oil composition, by calculating the weight of base oil as 100%, the screw type air compressor oil composition comprises the following components: 1-5% of high temperature anti-oxidant, 0.01-5% of extreme-pressure anti-grinding agent, 0.01-0.5% of corrosion resistance agent and 0.01-0.5% of antirust agent, wherein the high temperature anti-oxidant is composed of an amine type anti-oxidant, a phenol type anti-oxidant and a phosphite type anti-oxidant, and the weight ratio of amine type anti-oxidant to phenol type anti-oxidant to phosphite type anti-oxidant is 20: 30: 50-50: 30: 20; the phosphite type anti-oxidant is introduced in the screw compressor oil, and is synergized with the phenol or amine type anti-oxidant, compared with a common amine and phenol type anti-oxidant system, the antioxidation performance of the oil product can be greatly increased, the oil sludge generation trend can be better controlled, and the composition is suitable for the screw compressor oil which takes hydrogenation oil, PAO synthetic oil and semi-synthetic oil as base oil.

Description

technical field [0001] The invention relates to a lubricating oil composition, in particular to a lubricating oil composition which has good oxidation resistance, can reduce the tendency of sludge formation, and is suitable for screw air compressors. Background technique [0002] A compressor is a machine used to compress gas, increase the pressure of gas or transport gas. With the development of production technology, the types and structural forms of compressors are increasing day by day. Nowadays, compressors of various types and specifications are widely used in petrochemical, machinery manufacturing, civil engineering, mining and metallurgy, transportation, national defense, medical, textile and food and other fields. The screw air compressor that dominates the compressor, the lubricating oil used is in high temperature and high pressure environment in contact with the air for a long time, the lubricating oil is easily oxidized, causing the viscosity, acid value and sl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M141/10C10N30/10

Inventor 刘功德王辉

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com