Gas diffusion homogenization device and plasma process equipment using same

A technology of gas diffusion and plasma, applied in ion implantation plating, gaseous chemical plating, metal material coating process, etc., can solve the difficulty and cost of machining and assembly of vacuum chamber, cost increase, difficulty and High cost and other issues, to achieve the effect of improved gas diffusion uniformity, cost reduction, simple and reliable machining and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

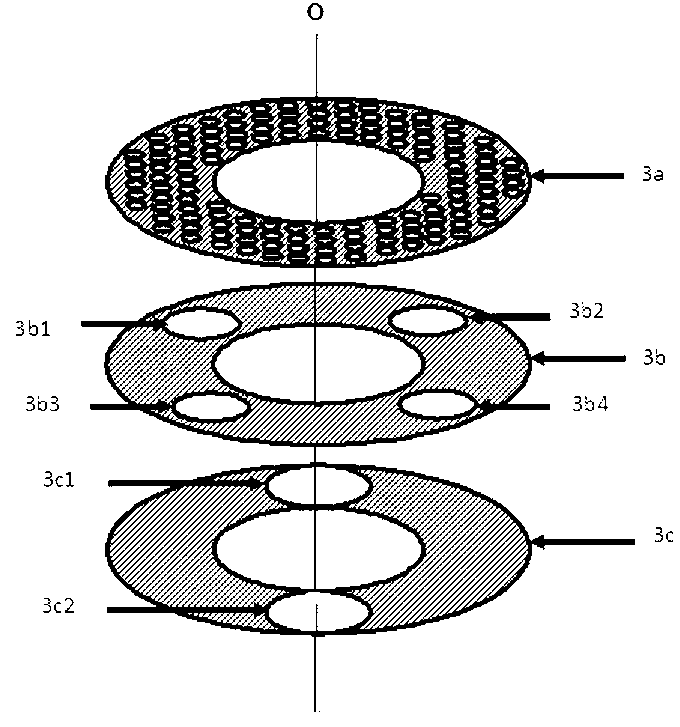

[0040] Such as image 3 As shown, an embodiment of the gas diffusion homogenization device provided by the present invention includes three diffusion rings, from top to bottom: the first diffusion ring 3a, the middle diffusion ring 3b and the bottom diffusion ring 3c, and the three diffusion rings From the appearance, it is three ring plates. Several gas through-holes are evenly arranged on the three diffusion rings, that is, the center distances of adjacent gas through-holes are equal, and the gas through-holes on the same diffusion ring are of equal size. The number and size of the gas passage holes on the diffusion rings of each layer are different. The gas through holes on the two adjacent layers of diffusion rings are staggered and symmetrically arranged, that is, the central axes of the gas through holes on the two layers of diffusion rings do not coincide with each other, and one gas through hole on a certain layer of diffusion rings There is an equal minimum distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com