Metal wire double boron coating tank

A metal wire, boron-coated tank technology, applied in the direction of metal material coating process, etc., can solve the problems of low production efficiency, large area and high production cost, and achieve the effect of saving space, prolonging life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

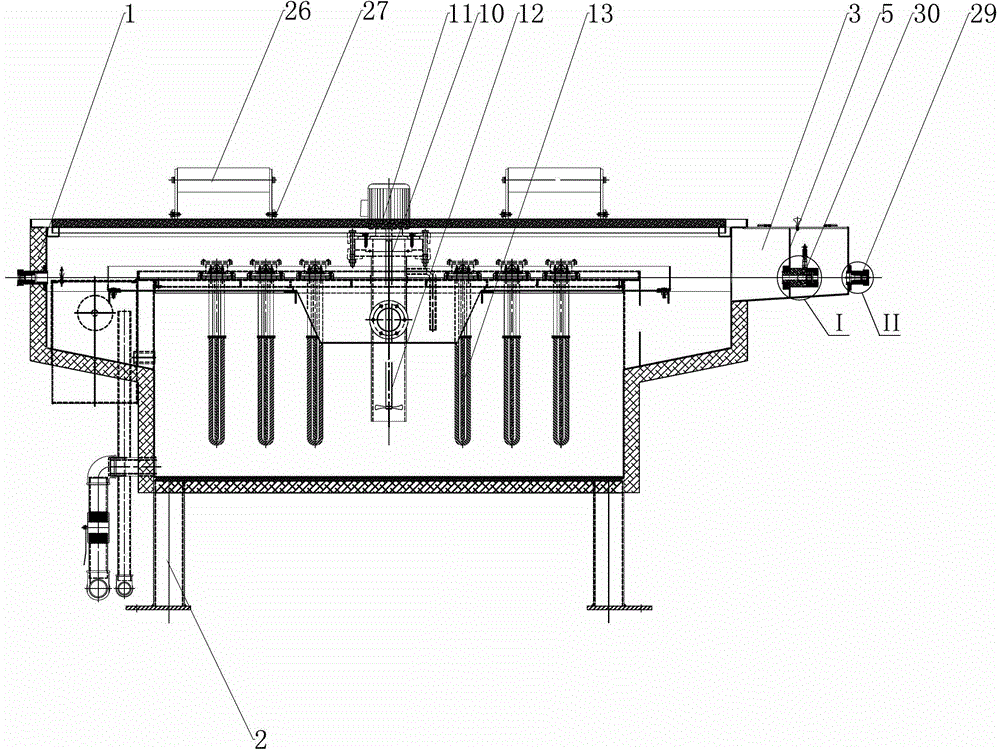

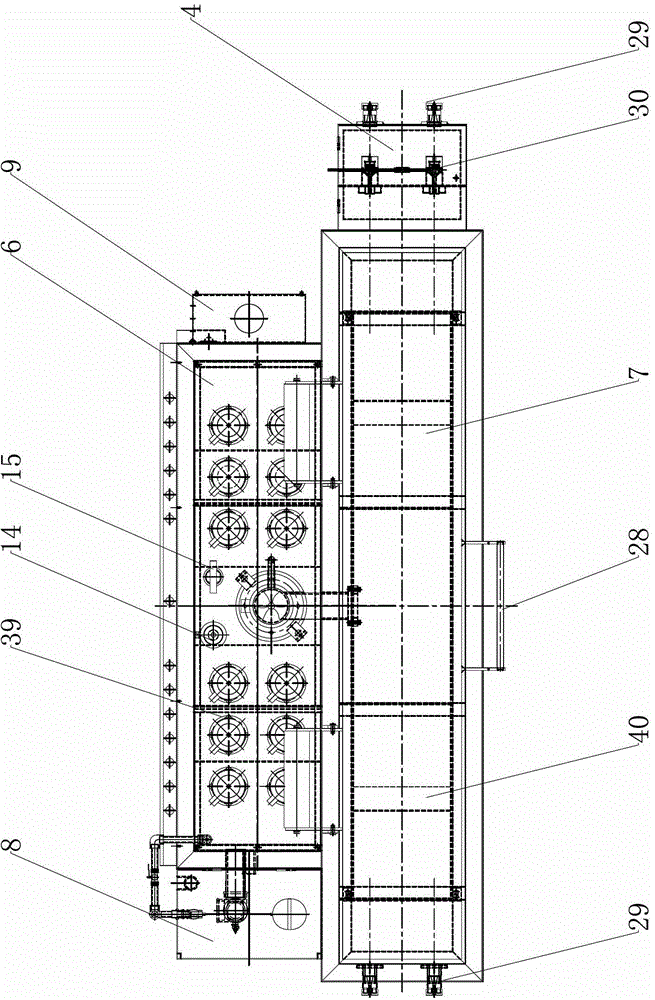

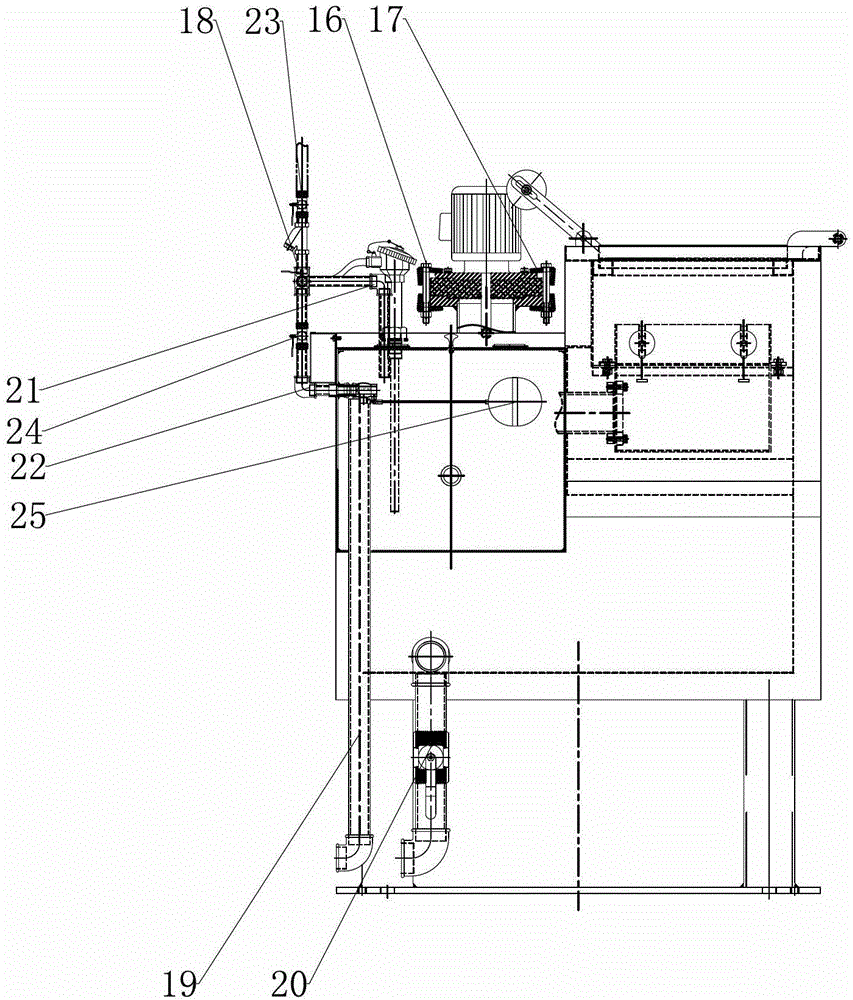

[0022] Such as Figure 1~3 As shown, the present invention mainly includes a tank body 1, the tank body 1 includes a heating chamber 39 and a boron-coated chamber 40 connected side by side, the heating chamber 39 fixes the heating box cover 6, and the upper end of the boron-coated chamber 40 is connected to the upper cover 7. The lifting pump 10 is installed on the heating box cover 6 by a positioning clip 17, and the positioning clip 17 is fastened on the heating box cover 6 by bolts 16. The lower end of the lift pump 10 is located in the tank body 1 . A plurality of flanged heating tubes 13 are installed on the heating box cover 6, and the flanged heating tubes 13 are located in the tank body 1, and the water in the tank body 1 is heated through the flanged heating tubes 13.

[0023] One end of the tank body 1 is connected to the liquid level contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com