A glass rib curtain wall system

A technology for glass ribs and curtain walls, applied to walls, building components, buildings, etc., can solve problems such as the difficulty in meeting the large span of glass ribs, the difficulty in ensuring the quality of glue injection, and the increase in the number or diameter of bolts at the top joints of glass ribs, etc., to achieve The effect of clear load transmission mode, reliable construction quality, and convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

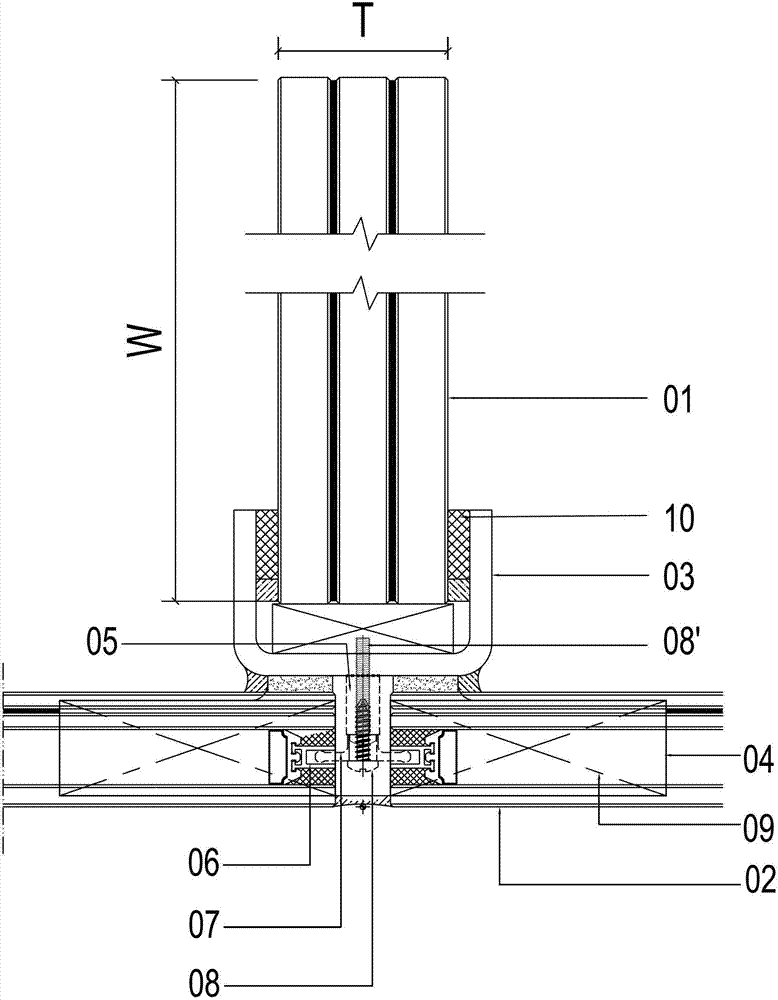

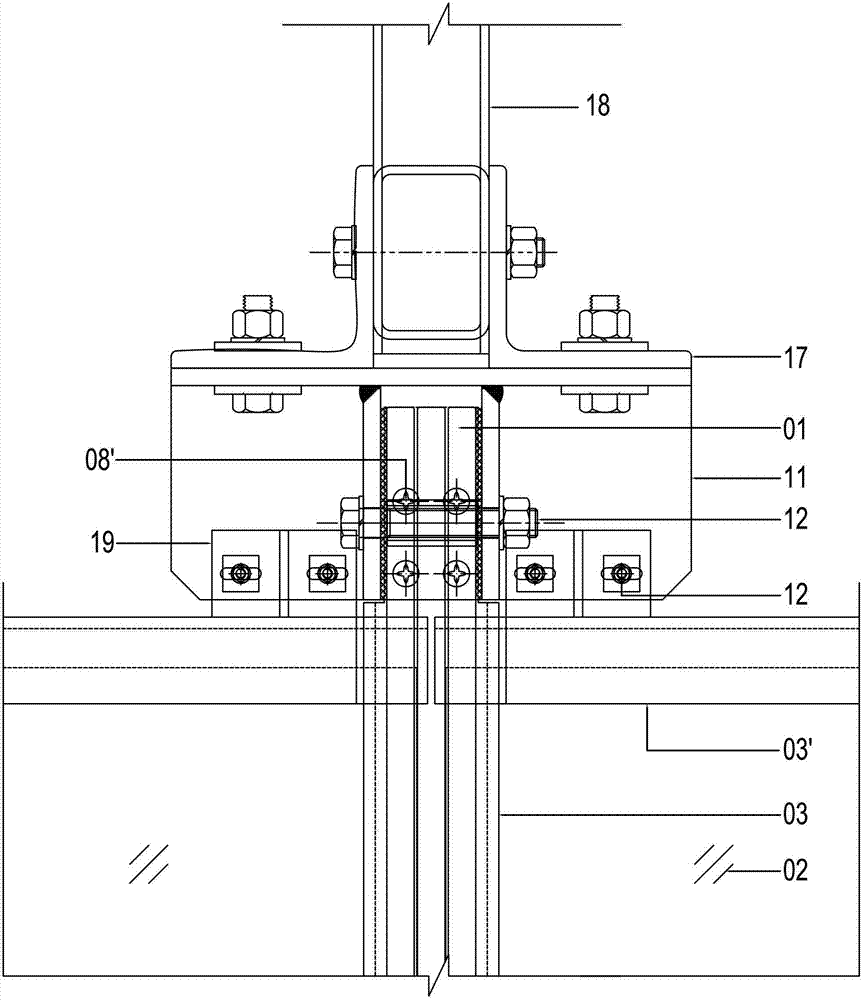

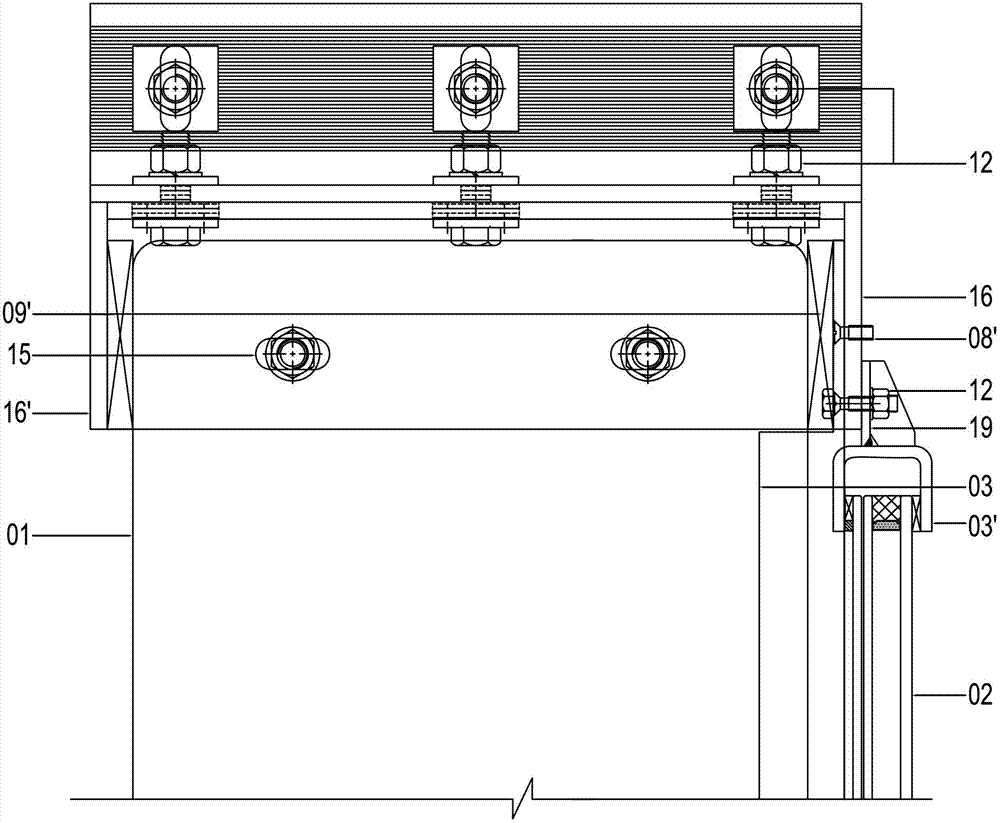

[0052] Such as Figure 1 to Figure 6 As shown, the vertical suspension connector in this embodiment is a vertical U-shaped groove 03, which extends at the longitudinal seam of the grid panel, and the horizontal support is a glass bracket 04, which is placed at the horizontal joint of the grid panel. Seam, which is fixedly connected with the vertical U-shaped groove 03. In this embodiment, the glass rib holder 04 is welded and fixedly connected with the vertical U-shaped groove 03, and the connection between the U-shaped groove and the main structure 18 is fastened. Parts use bolt 12.

[0053] Specifically, the height of the glass rib 01 reaches 10.76m, and the matching glass surface is divided into grids, and the divided glass panel 02 is divided into three pieces in the vertical direction, for example, and the width of each divided glass panel is 1.8m. The connection between the glass panels 02 of the glass grid is a fully hidden frame structure, such as figure 1 As shown, ...

Embodiment 2

[0059] Such as Figures 7 to 12 In the illustrated embodiment, the longitudinal suspension connectors are tie rods 23 and the transverse supports are beams 21 . The connecting fastener between glass rib 01 and main structure 18 adopts pin shaft 12' (see Figure 11 ). Pull rod 23 is arranged on the back of glass panel 02 parallel to the longitudinal seam of glass panel 02 , beam 21 is embedded in the transverse seam of glass panel 02 to support glass panel, and cross beam 21 is fixedly connected with pull rod 23 . Such as Figure 7 As shown, the beam is disconnected at the glass rib 01, and the two ends are fixed on the two opposite sides in the width direction of the glass rib through the adapter. The adapter and the glass rib are pierced with connection holes, in which bolts 12 Fix the beam 21 and the glass rib 01 together.

[0060] The combination of tie rods and beams is suitable for the case where the horizontal division of glass panel 02 is relatively large, generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com