High-molecular rapid rotary screen blue-light plate-making photosensitive resist

A technology of polymer and photosensitive adhesive, which is applied in the direction of photoplate making process, optics, and optomechanical equipment on the pattern surface, which can solve the problems of long time and achieve increased density, high resolution, and good photocrosslinking and curing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

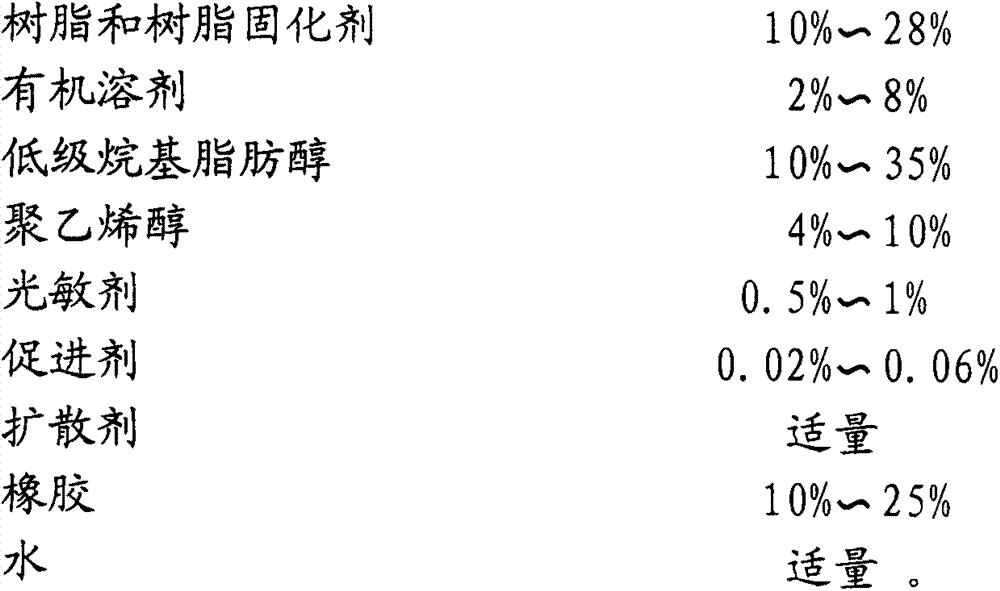

[0026] The macromolecule fast rotary screen blue-ray plate-making photosensitive adhesive provided by the invention is composed of the following compounds (weight):

[0027]

Embodiment 2

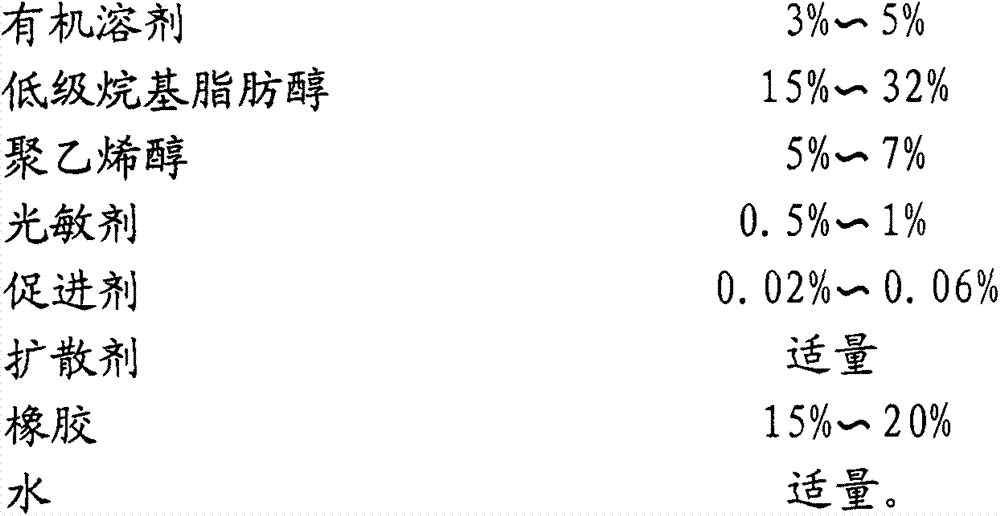

[0029] The macromolecule fast rotary screen blue-ray plate-making photosensitive adhesive provided by the invention is composed of the following compounds (weight):

[0030]

Embodiment 3

[0032] The macromolecule fast rotary screen blue-ray plate-making photosensitive adhesive provided by the invention is composed of the following compounds (weight):

[0033]

[0034] The materials in the formulas of the above three examples are mixed and stirred evenly, and then coated on the circular net for drying. The dried adhesive layer is photosensitive, and the 720dpi ultraviolet laser spots emitted by the LD blue-ray network equipment undergo photocrosslinking reactions. Then it is developed by water, baked at high temperature, and cured to form a fast screen-making adhesive layer, which is suitable for rotary screen blue-ray plate-making in reactive printing and anti-discharge printing processes.

[0035] The photosensitive adhesive for polymer fast rotary screen blue-ray plate-making provided by the present invention adopts interpenetrating network technology and new materials, so that each component is cross-linked to form an interpenetrating network, and the dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com